Please Choose Your Language

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

The 400T high-precision injection molding machine is engineered for medium-large plastic products that demand excellent stability and smooth surface quality. Powered by a servo hydraulic system, it delivers fast response, strong clamping force, and reduced energy consumption. Its optimized screw and injection unit ensure consistent melt flow, making it suitable for a wide range of industrial and consumer plastic applications.

| Availability: | |

|---|---|

| Quantity: | |

NT400

Leantall

400T

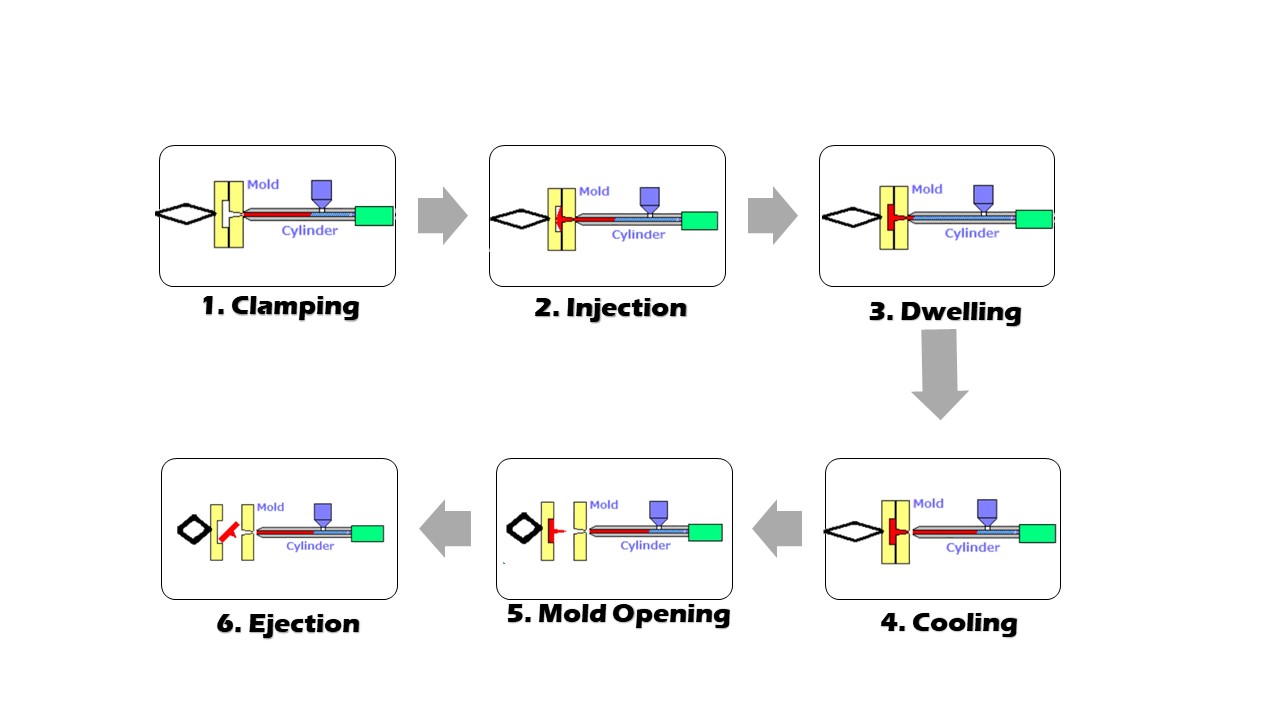

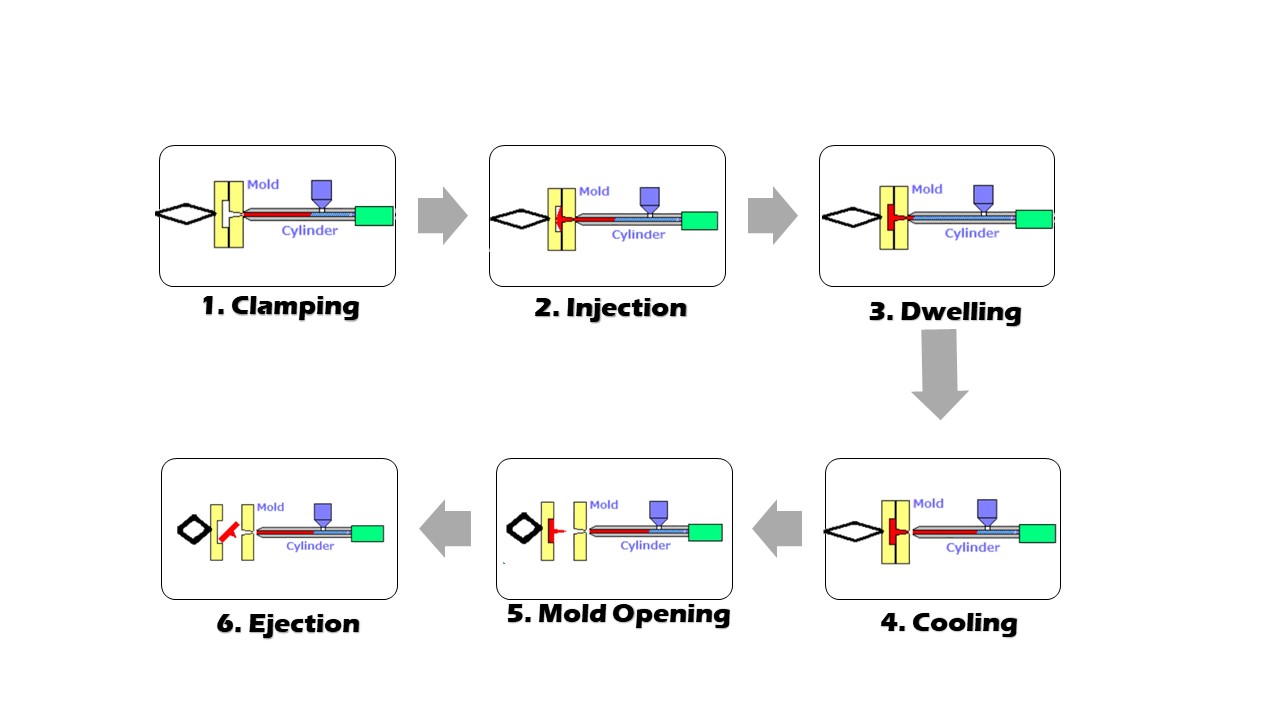

The 400T injection machine follows a complete and efficient molding cycle that ensures product uniformity and dimensional accuracy. During the injection process, plastic pellets are fed into the barrel, heated to a molten state, and injected into the mold cavity under precisely controlled pressure. Once filled, the mold is held under pressure to prevent shrinkage and ensure structural integrity. After cooling and solidifying, the mold opens and ejects the finished product, making the entire cycle highly efficient and repeatable for mass production.

With its balanced clamping force and large-platen design, the 400T machine is ideal for producing medium-large plastic parts such as automotive interior components, household appliance covers, plastic crates, storage boxes, industrial trays, instrument panels, baby bathtub shells, dustbins, and multi-functional daily-use products. It supports a variety of materials including PP, ABS, HDPE, and reinforced plastics, providing excellent flexibility for diverse manufacturing needs.

Part | Name | Unit | 400 | ||

Injection Unit

| SCREW DIAMETER | mm | 70 | 75 | 80 |

SCREW L/D RATIO | L/D | 21.4 | 20 | 19 | |

INJECTION STROKE | mm | 390 | 390 | 390 | |

NJECTION SPEED | Mm/sec | 97 | 97 | 97 | |

SHOT VOLUME(THEORETICAL) | CM3 | 1501 | 1723 | 1960 | |

INJECTION WEIGHT(PS) | g | 1366 | 1568 | 1784 | |

INJECTION PRESSURE | Mpa | 194 | 169 | 148 | |

INJECTION RATE | cm⊃3;/sec | 373 | 428 | 487 | |

SCREW SPEED | rpm | 170 | |||

Clamping Unit

| CLAMP FORCE | Kn | 4000 | ||

OPEN STROKE | mm | 725 | |||

SPACE BETWEEN TIE BARS | mm×mm | 730X730 | |||

MAX.MOULD HEIGHT | mm | 780 | |||

MIN.MOULD HEIGHT | mm | 250 | |||

EJECTOR STROKE | mm | 150 | |||

EJECTOR FORCE | Kn | 79 | |||

EJECTOR NUMBER | N | 13 | |||

Others

| MAX.PUMP PRESSURE | Mpa | 16 | ||

SEVRO DRIVE POWER | Kw | 55 | |||

HEATING POWER | Kw | 29.5 | |||

MACHINE DIMENSION(L*W*H) | m×m×m | 7.6*1.85*2.35 | |||

MACHINE WEIGHT(ESTIMATE) | T | 16 | |||

This injection molding machine stands out for 4 core strengths: First, its precise control ensures uniform plastic part quality, avoiding defects. Second, fast cycle times boost production efficiency—critical for tight deadlines. Third, wide adaptability fits automotive, electronics, packaging sectors, plus both small-batch prototypes and large-scale runs. Lastly, the plastic injection machine uses energy-saving tech, slashing operational costs while maintaining reliability. These traits make it a cost-effective, versatile choice for plastic manufacturing.

You know energy bills can eat into profits. Our machine’s servo motor uses up to 30% less electricity than standard models. The intelligent control system reduces idle energy waste, too. You’ll see savings month after month, making your production more cost-effective.

A 400-ton clamping force means it handles large molds with ease. The robust steel frame and precision hydraulic system ensure stable operation, even during continuous 24/7 runs. You won’t have to worry about vibrations or misalignment affecting your parts’ quality.

You don’t want a machine that’s hard to use. Our intuitive control panel lets you set parameters quickly—mold size, injection speed, cooling time. Real-time diagnostics alert you to issues before they become problems, minimizing downtime and training costs.

Let’s break it down. First, the hopper feeds plastic pellets into the heating barrel. The screw melts the plastic and injects it into the mold under high pressure. The 400-ton clamp holds the mold tight to prevent leaks. Once the part cools, the clamp opens, and the ejector pushes out the finished product. The servo motor adjusts speed and pressure dynamically, ensuring every cycle is efficient and accurate. You get high-quality parts, fast—without wasting energy or material.

You need consistent, durable packaging. Use this machine to mold plastic boxes, crates, or trays. The large tonnage handles thick-walled designs, while energy savings help keep your packaging costs low.

Precision is key for automotive parts. The stable clamping force ensures complex parts like dash panels or engine components have clean edges and tight tolerances. You’ll meet industry standards without extra effort.

From buckets to furniture parts, this machine handles diverse materials—PP, PE, ABS. The energy-saving design is perfect for high-volume production, so you can meet consumer demand efficiently.

You deserve a machine that works as hard as you do. Our 400-ton energy-saving injection machine offers power, precision, and savings—all in one. It’s built for businesses that want to grow without compromising on costs or quality. Don’t let inefficient machines hold you back. Upgrade today and see the difference in your production line’s performance and your bottom line.

The 400T injection machine follows a complete and efficient molding cycle that ensures product uniformity and dimensional accuracy. During the injection process, plastic pellets are fed into the barrel, heated to a molten state, and injected into the mold cavity under precisely controlled pressure. Once filled, the mold is held under pressure to prevent shrinkage and ensure structural integrity. After cooling and solidifying, the mold opens and ejects the finished product, making the entire cycle highly efficient and repeatable for mass production.

With its balanced clamping force and large-platen design, the 400T machine is ideal for producing medium-large plastic parts such as automotive interior components, household appliance covers, plastic crates, storage boxes, industrial trays, instrument panels, baby bathtub shells, dustbins, and multi-functional daily-use products. It supports a variety of materials including PP, ABS, HDPE, and reinforced plastics, providing excellent flexibility for diverse manufacturing needs.

Part | Name | Unit | 400 | ||

Injection Unit

| SCREW DIAMETER | mm | 70 | 75 | 80 |

SCREW L/D RATIO | L/D | 21.4 | 20 | 19 | |

INJECTION STROKE | mm | 390 | 390 | 390 | |

NJECTION SPEED | Mm/sec | 97 | 97 | 97 | |

SHOT VOLUME(THEORETICAL) | CM3 | 1501 | 1723 | 1960 | |

INJECTION WEIGHT(PS) | g | 1366 | 1568 | 1784 | |

INJECTION PRESSURE | Mpa | 194 | 169 | 148 | |

INJECTION RATE | cm⊃3;/sec | 373 | 428 | 487 | |

SCREW SPEED | rpm | 170 | |||

Clamping Unit

| CLAMP FORCE | Kn | 4000 | ||

OPEN STROKE | mm | 725 | |||

SPACE BETWEEN TIE BARS | mm×mm | 730X730 | |||

MAX.MOULD HEIGHT | mm | 780 | |||

MIN.MOULD HEIGHT | mm | 250 | |||

EJECTOR STROKE | mm | 150 | |||

EJECTOR FORCE | Kn | 79 | |||

EJECTOR NUMBER | N | 13 | |||

Others

| MAX.PUMP PRESSURE | Mpa | 16 | ||

SEVRO DRIVE POWER | Kw | 55 | |||

HEATING POWER | Kw | 29.5 | |||

MACHINE DIMENSION(L*W*H) | m×m×m | 7.6*1.85*2.35 | |||

MACHINE WEIGHT(ESTIMATE) | T | 16 | |||

This injection molding machine stands out for 4 core strengths: First, its precise control ensures uniform plastic part quality, avoiding defects. Second, fast cycle times boost production efficiency—critical for tight deadlines. Third, wide adaptability fits automotive, electronics, packaging sectors, plus both small-batch prototypes and large-scale runs. Lastly, the plastic injection machine uses energy-saving tech, slashing operational costs while maintaining reliability. These traits make it a cost-effective, versatile choice for plastic manufacturing.

You know energy bills can eat into profits. Our machine’s servo motor uses up to 30% less electricity than standard models. The intelligent control system reduces idle energy waste, too. You’ll see savings month after month, making your production more cost-effective.

A 400-ton clamping force means it handles large molds with ease. The robust steel frame and precision hydraulic system ensure stable operation, even during continuous 24/7 runs. You won’t have to worry about vibrations or misalignment affecting your parts’ quality.

You don’t want a machine that’s hard to use. Our intuitive control panel lets you set parameters quickly—mold size, injection speed, cooling time. Real-time diagnostics alert you to issues before they become problems, minimizing downtime and training costs.

Let’s break it down. First, the hopper feeds plastic pellets into the heating barrel. The screw melts the plastic and injects it into the mold under high pressure. The 400-ton clamp holds the mold tight to prevent leaks. Once the part cools, the clamp opens, and the ejector pushes out the finished product. The servo motor adjusts speed and pressure dynamically, ensuring every cycle is efficient and accurate. You get high-quality parts, fast—without wasting energy or material.

You need consistent, durable packaging. Use this machine to mold plastic boxes, crates, or trays. The large tonnage handles thick-walled designs, while energy savings help keep your packaging costs low.

Precision is key for automotive parts. The stable clamping force ensures complex parts like dash panels or engine components have clean edges and tight tolerances. You’ll meet industry standards without extra effort.

From buckets to furniture parts, this machine handles diverse materials—PP, PE, ABS. The energy-saving design is perfect for high-volume production, so you can meet consumer demand efficiently.

You deserve a machine that works as hard as you do. Our 400-ton energy-saving injection machine offers power, precision, and savings—all in one. It’s built for businesses that want to grow without compromising on costs or quality. Don’t let inefficient machines hold you back. Upgrade today and see the difference in your production line’s performance and your bottom line.