Please Choose Your Language

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 100 Author: Site Editor Publish Time: 2025-11-27 Origin: Site

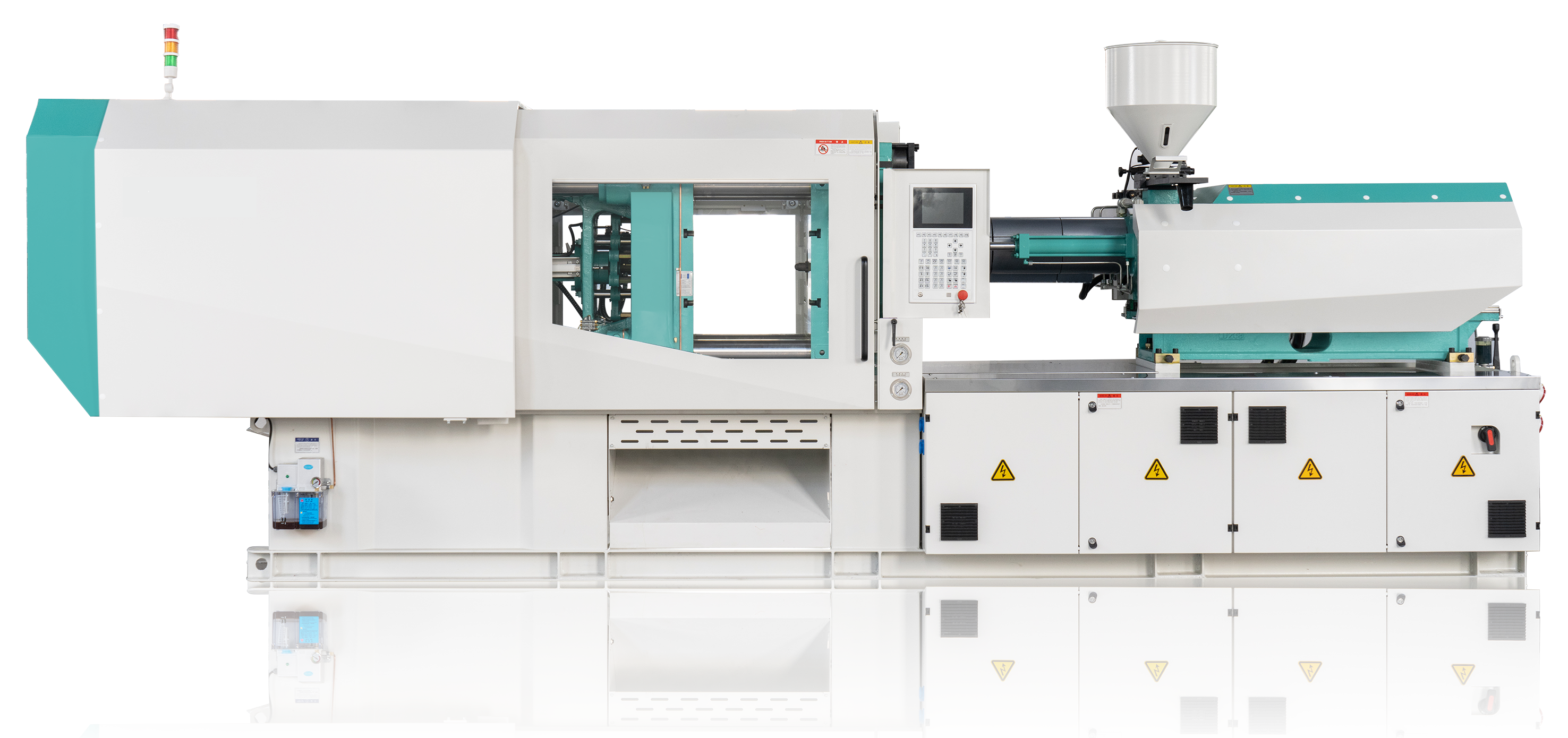

Plastic injection molding is a widely used manufacturing process that shapes plastic materials into products by injecting molten plastic into a mold. While the injection molding machine (IMM) itself plays a central role in the process, a range of auxiliary equipment is equally important to ensure the system runs efficiently and effectively. These devices enable the injection molding machine to operate at peak performance, improve productivity, and reduce human intervention—leading to a fully automated production process.

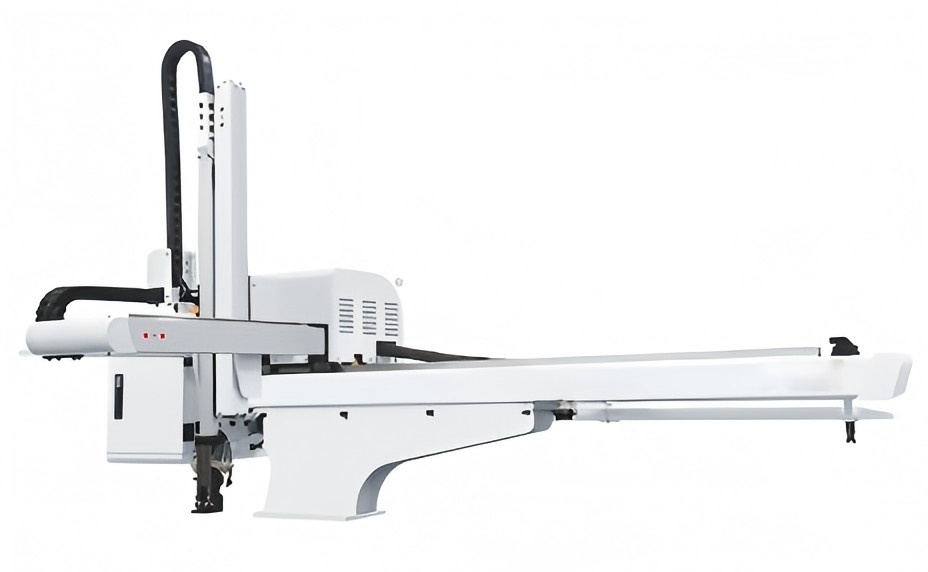

One of the key challenges in injection molding is the handling of products after they have been molded. This is where a manipulator comes into play. Installed directly on the injection molding machine, the manipulator is an automated system designed to grab the molded runners (the material used in the injection process but not part of the final product) or the finished products themselves. It can move them to other parts of the production line for further processing, such as assembly, packaging, or sorting.

By automating the process of product handling, the manipulator reduces the need for manual labor and minimizes the risk of defects caused by human error. This contributes to a smoother, faster production cycle.

The auto suction loader is a vital piece of equipment used to feed raw material particles into the injection molding machine's hopper. It is designed to automatically suck plastic pellets, resin, or other materials from a storage bin or silo and transport them into the hopper of the injection molding machine. This ensures a continuous supply of material during the production cycle, eliminating the need for manual feeding and reducing downtime.

The auto suction loader also helps to maintain the proper material flow rate, ensuring consistent quality in the molded products. Its automation capabilities improve efficiency and prevent material wastage due to inconsistent feeding.

In any plastic injection molding operation, there will inevitably be waste material—whether from sprues, runners, or parts that do not meet quality standards. To maximize material efficiency, a crusher is used to break down these plastic waste products into smaller, reusable pieces. The crushed material can be recycled and reintroduced into the production process, reducing the amount of new material needed.

Not only does this help to lower production costs, but it also supports sustainability efforts by minimizing waste and the environmental impact of the manufacturing process.

To ensure consistent quality in the finished products, it is essential that the raw materials and any color additives are properly blended. The mixer is the equipment used to achieve this. Installed before the hopper, the mixer combines plastic pellets or resin with color masterbatches (concentrated colorants in pellet form) to create a homogeneous mixture.

This is especially important for industries where product color consistency is crucial, such as in the automotive or consumer goods sectors. The mixer ensures that every batch of material used in the molding process has the same color and material properties, leading to higher-quality and more aesthetically appealing products.

One of the key factors influencing the quality of molded parts is the temperature of the mold during the injection process. A chiller plays an essential role in maintaining the inner mold temperature at an optimal level. Mold cooling is necessary for the solidification of the plastic after it has been injected into the mold cavity. If the temperature is too high, the molded part may become deformed, while if the temperature is too low, it can cause the part to stick to the mold, resulting in defects.

The chiller circulates coolant through channels within the mold, regulating the temperature and ensuring consistent cooling throughout the molding process. This leads to higher precision, better product quality, and faster cycle times.

In addition to the chiller, a cooling water tower is essential for dissipating the heat generated by the injection molding machine during its operation. Injection molding machines generate significant heat as they melt plastic and inject it into molds, and this heat must be effectively removed to prevent overheating and maintain consistent operation.

The cooling water tower acts as a heat exchange system, transferring the excess heat from the machine's cooling system to the surrounding environment. By regulating the temperature of the machine and its components, the cooling water tower helps maintain a stable operating environment, which is crucial for ensuring both the quality and efficiency of the molding process.

The integration of these auxiliary systems into the injection molding process offers numerous benefits:

Full Automation: The combination of manipulators, auto suction loaders, crushers, mixers, chillers, and cooling water towers allows for a fully automated production process. This minimizes manual intervention, improves production speed, and reduces the likelihood of human errors.

Cost-Effectiveness: Despite the upfront investment, auxiliary equipment offers long-term cost savings by reducing labor costs, material waste, and downtime. For instance, the crusher and auto suction loader contribute to material savings, while the manipulator and mixer improve operational efficiency.

Improved Productivity: With auxiliary equipment, the injection molding machine can operate at higher speeds and with greater precision, improving overall throughput and reducing cycle times. This is especially important in industries with high production demands.

Multiple Models Available: Manufacturers can select from a range of auxiliary equipment models tailored to specific needs. Whether it's a more basic system for small-scale operations or advanced automated systems for large-scale production lines, there are multiple models available to suit a variety of applications.

In conclusion, the auxiliary equipment used alongside plastic injection molding machines plays a crucial role in optimizing the entire production process. From ensuring a continuous material supply with suction loaders to maintaining mold temperatures with chillers and cooling towers, each piece of equipment enhances the efficiency, quality, and sustainability of the operation. These systems, while highly cost-effective, contribute to a fully automated and streamlined production environment—making them indispensable in the modern world of plastic manufacturing.