Please Choose Your Language

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 1000 Author: Site Editor Publish Time: 2025-11-27 Origin: Site

High-Performance Injection Molding Machines: Key Features and Benefits

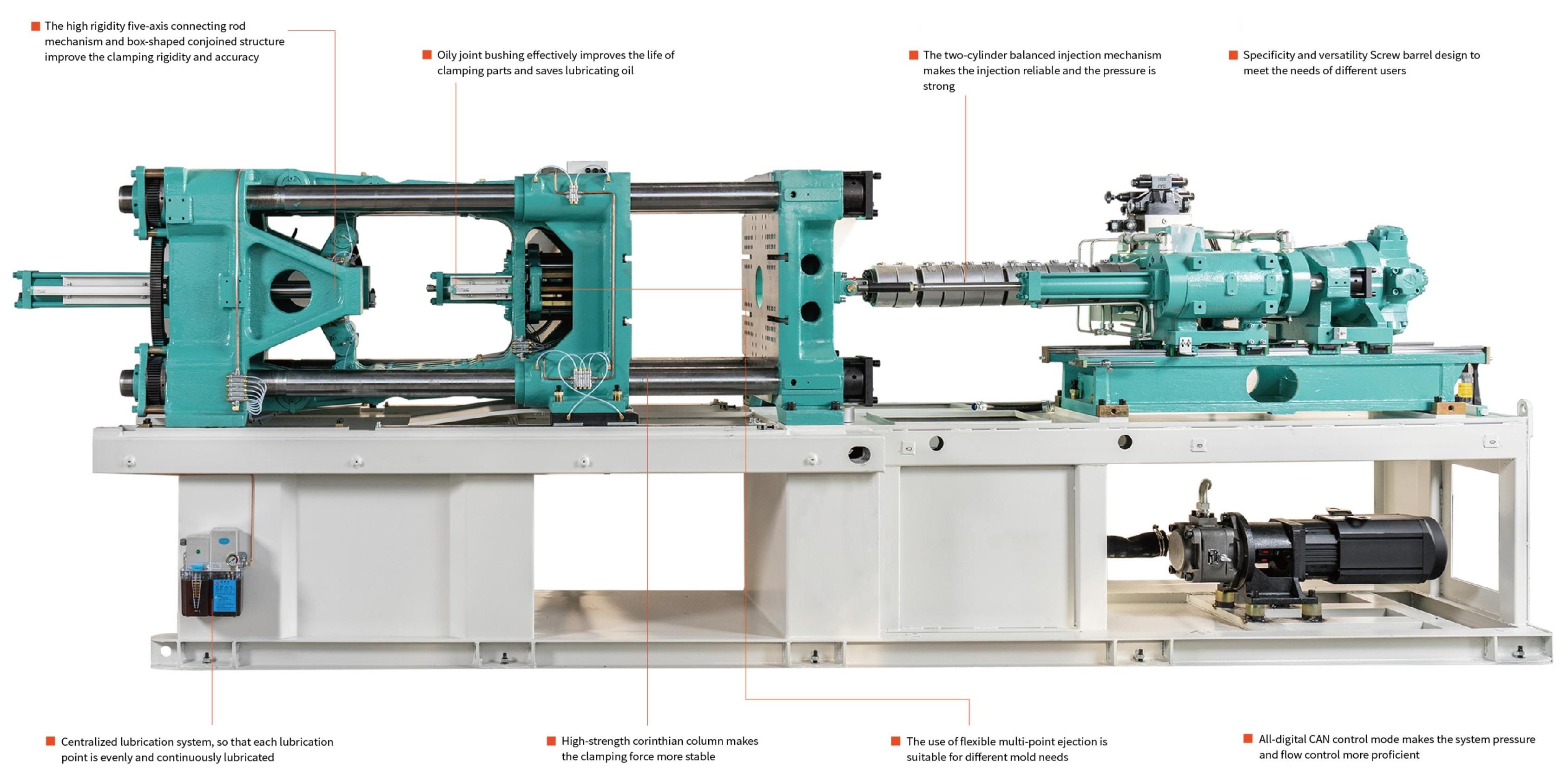

Injection molding is a widely used manufacturing process that allows for the production of precision parts in high volumes. The quality and efficiency of an injection molding machine are critical to meeting the demands of modern industries. Our injection molding machines are engineered for excellence, designed to deliver consistent results while enhancing productivity. Here’s an overview of the key features that make our machines stand out in the market:

At the heart of our injection molding machines is a high-quality, precisely engineered structure that ensures consistent performance and durability. The precise design of the machine guarantees that each component works in harmony, allowing for improved part accuracy and higher overall machine reliability. This attention to detail results in better molded parts with minimal defects, reducing waste and ensuring high production standards.

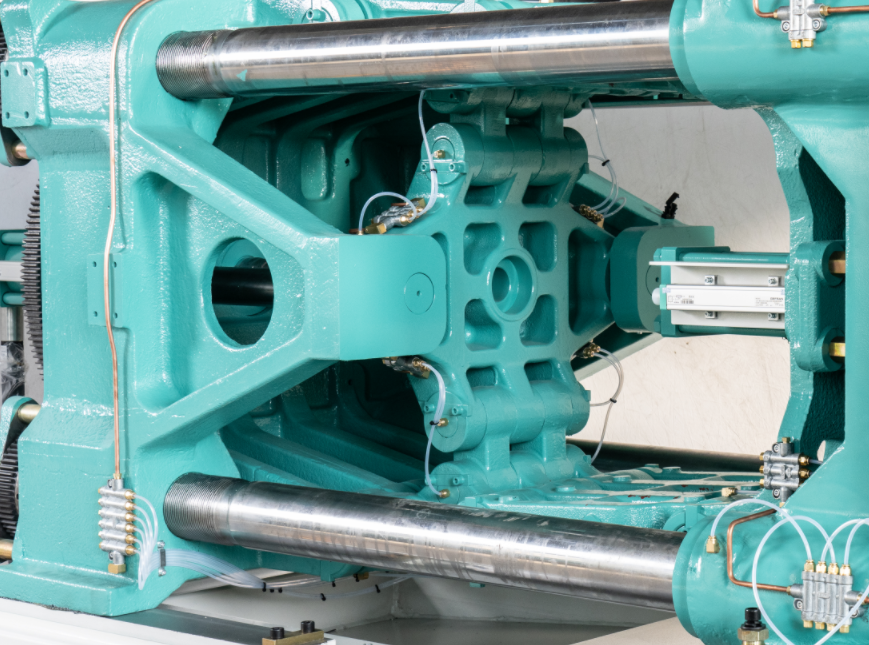

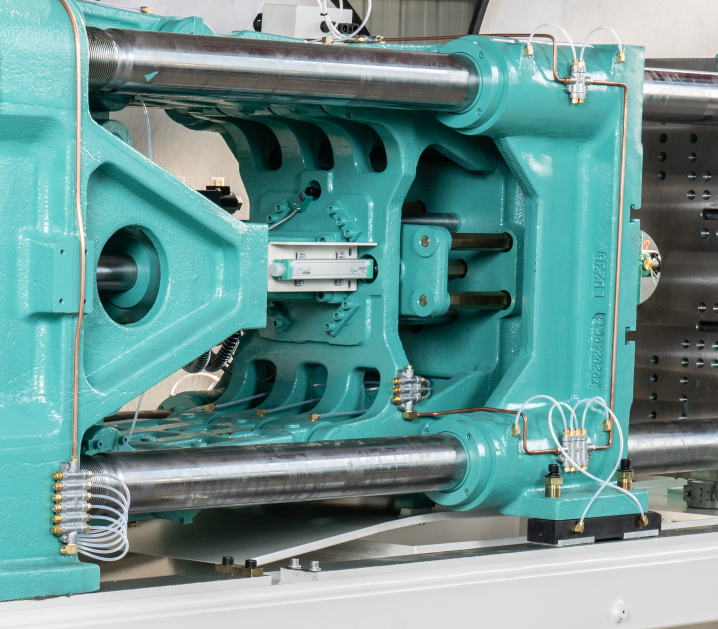

The advanced high-rigidity five-axis connecting rod mechanism is one of the standout features of our injection molding machine. This mechanism, combined with a box-shaped conjoined structure, significantly enhances the clamping rigidity and accuracy. By improving clamping stability, we ensure that mold alignment is precise, leading to better consistency in part quality. Whether you’re producing large or small components, this system provides the strength and stability necessary for reliable and repeatable results.

To improve the longevity of the clamping parts, our machine incorporates an oily joint bushing that effectively reduces wear and tear. This innovation not only extends the service life of critical components but also helps in saving lubricating oil by ensuring that lubrication is optimized. The result is lower maintenance costs and reduced downtime, making it a cost-effective solution for high-volume production environments.

Our machine features a two-cylinder balanced injection mechanism, which enhances the reliability of the injection process. This dual-cylinder system ensures that injection pressure is strong and uniform, delivering precise and consistent material flow into the mold cavity. Whether you are working with high-viscosity materials or need to inject delicate parts, this system ensures optimal performance, reducing cycle times and improving overall efficiency.

The screw barrel design is a key feature of our injection molding machine that offers both specificity and versatility. It is specifically designed to accommodate the needs of various users and materials. By tailoring the screw barrel to different material types and processing requirements, our machine can handle a wide range of applications, from thermoplastics to specialized resins. This flexibility ensures that our machine can meet the diverse needs of industries such as automotive, electronics, and medical device manufacturing.

A well-maintained lubrication system is essential for the smooth operation of any injection molding machine. Our machine comes equipped with a centralized lubrication system that ensures each lubrication point is evenly and continuously lubricated. This system reduces friction between moving parts, prolonging the lifespan of the machine and minimizing the need for frequent maintenance. By automating the lubrication process, we also improve efficiency and reduce operator intervention.

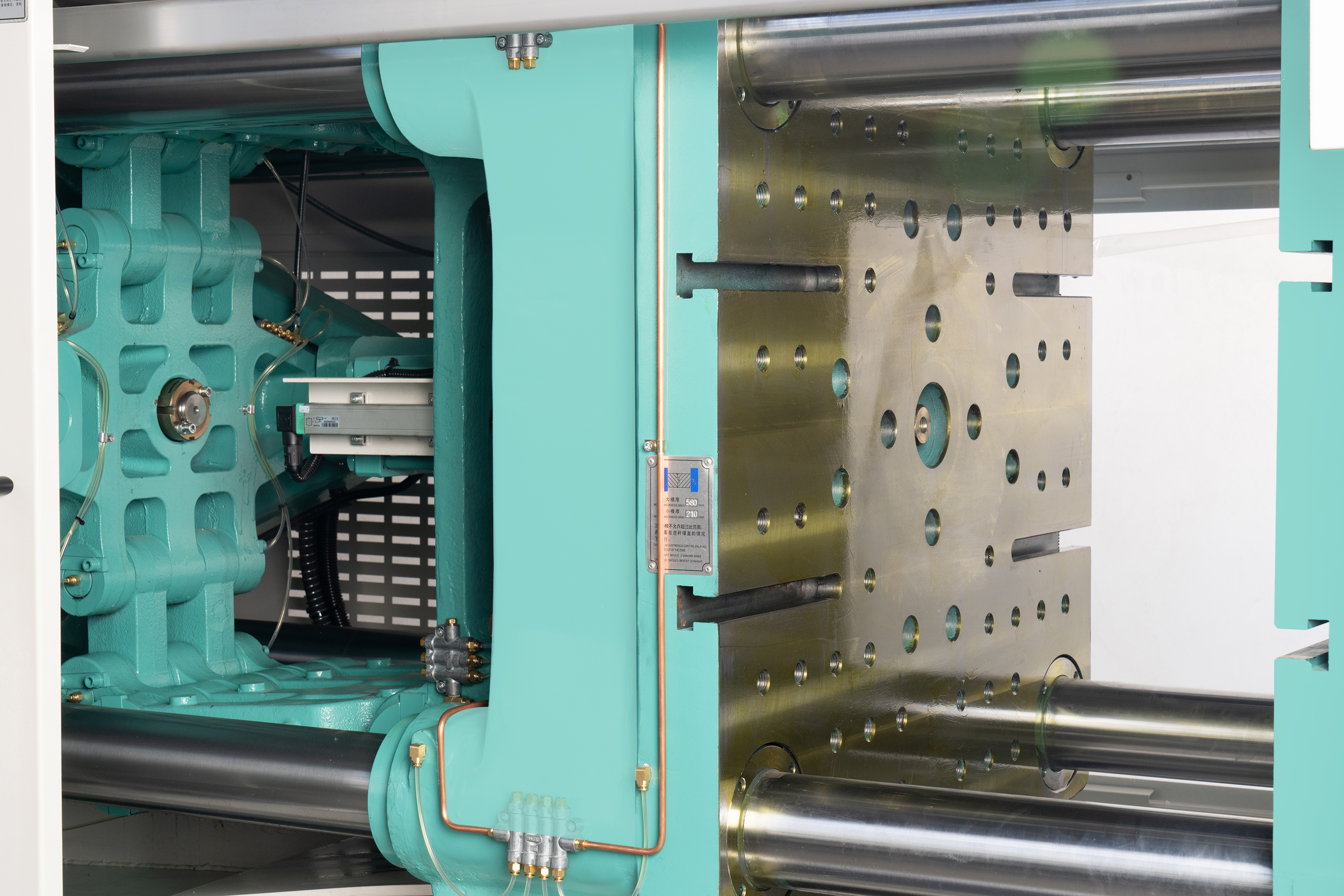

The use of a high-strength Corinthian column in our injection molding machine is a critical design feature that contributes to more stable clamping force. This robust component ensures that the clamping pressure remains constant, even during high-speed cycles, allowing for more accurate and reliable molding. With a stable clamping force, the machine produces higher-quality parts with fewer defects, meeting the most stringent production requirements.

The versatility of our injection molding machine is further enhanced by the use of flexible multi-point ejection. This feature allows the machine to accommodate different mold needs, ensuring that parts are ejected efficiently without damaging the mold or the finished component. Whether the mold is large or small, simple or complex, the flexible multi-point ejection system ensures consistent performance across a wide range of applications.

Our injection molding machine employs an all-digital CAN (Controller Area Network) control mode, which offers superior control over system pressure and flow. This advanced control system ensures that the machine operates at peak efficiency, with precise adjustments made in real-time to optimize injection performance. The result is improved repeatability, reduced scrap rates, and enhanced overall production efficiency.

The combination of advanced engineering and high-quality components makes our injection molding machines the ideal choice for manufacturers looking to optimize their production processes. With features like a high-rigidity five-axis connecting rod mechanism, reliable two-cylinder injection system, and centralized lubrication, our machines deliver precision, stability, and versatility. Whether you’re producing complex components or high-volume parts, our injection molding machines are designed to meet the needs of modern manufacturing with unparalleled performance and efficiency.

By incorporating cutting-edge technologies and innovative designs, we ensure that our machines not only meet but exceed industry expectations, making them a trusted solution for businesses around the world.