Please Choose Your Language

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

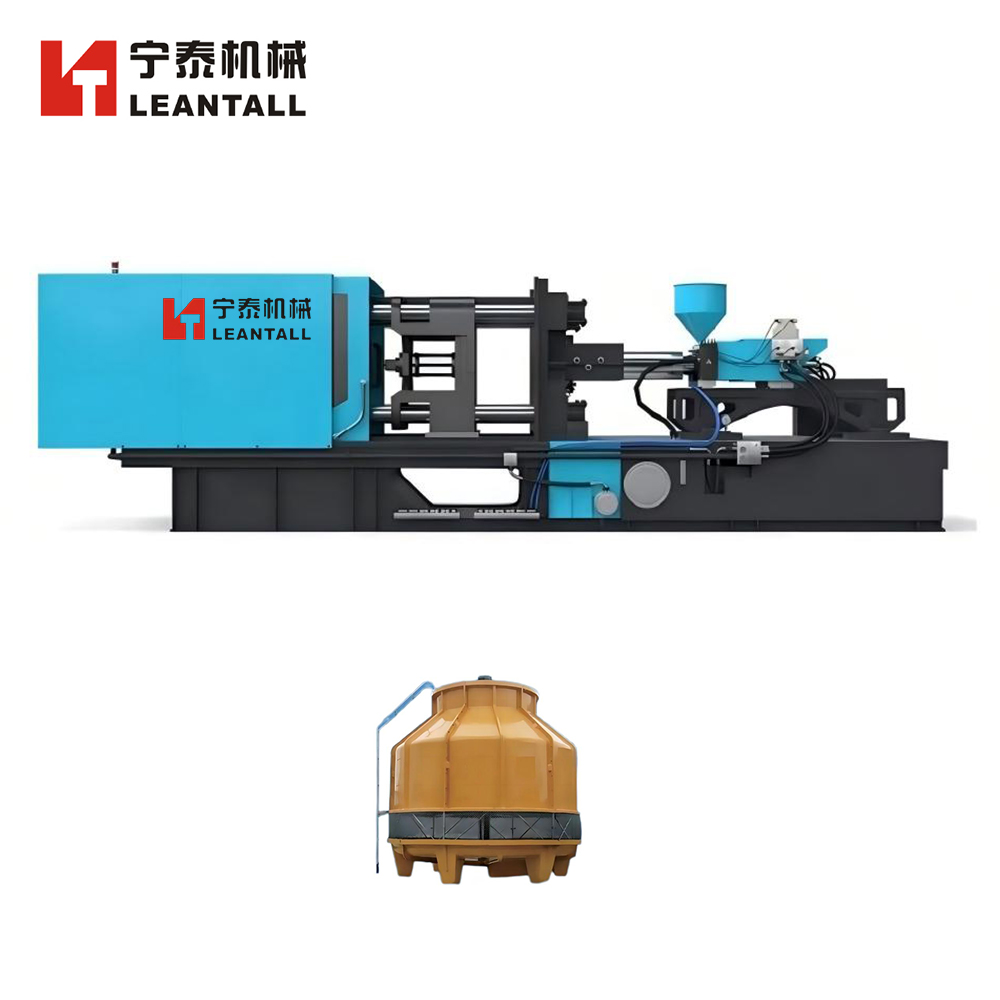

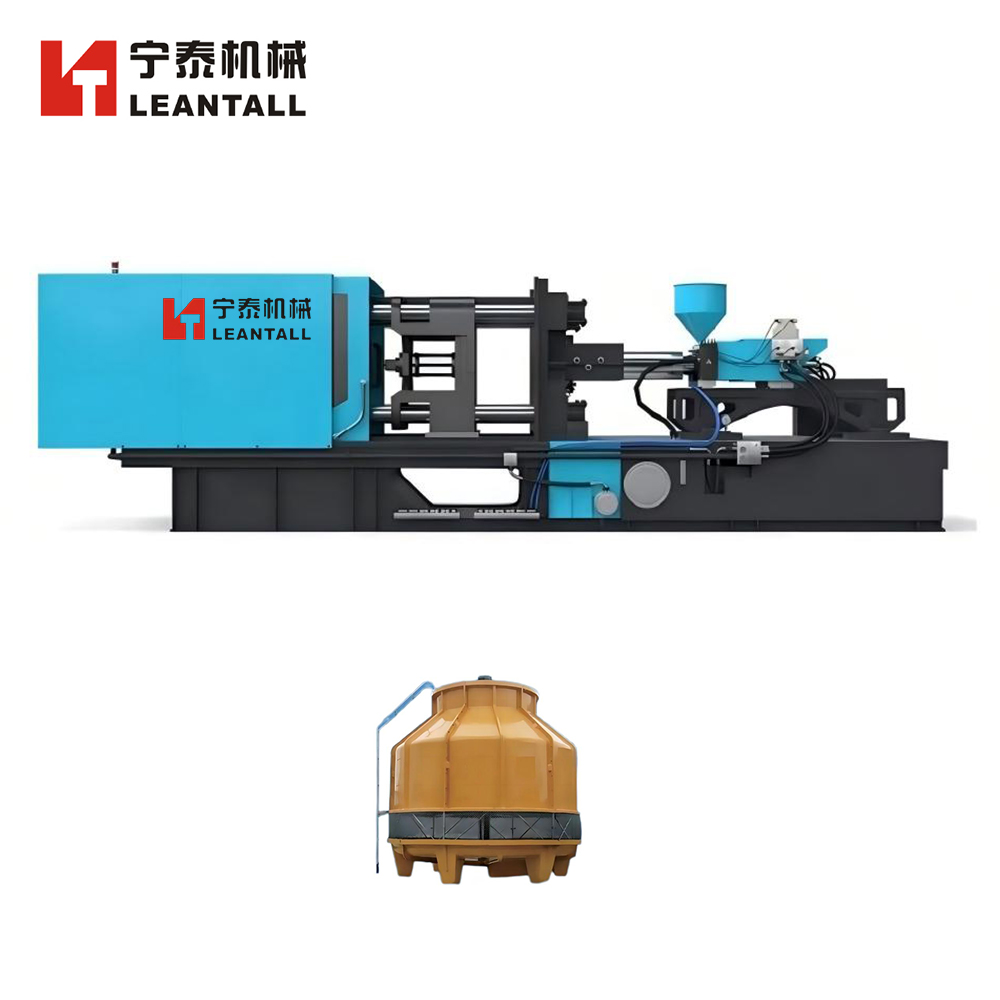

50T

LEANTALL

Product Description

Industrial 50T Water Cooling Tower

An injection molding machine cooling tower is a crucial component in the injection molding process, designed to maintain optimal temperature conditions for the machine and improve the overall efficiency of production. These cooling towers are used to cool down the circulating water or other cooling fluids that pass through the injection molding machine's cooling system.

Function:

The primary function of a cooling tower for injection molding machines is to dissipate the heat generated during the molding process. Injection molding machines operate at high temperatures, and maintaining a consistent, controlled temperature is essential for product quality and mold longevity. The cooling tower works by circulating water through the machine’s cooling channels, absorbing the excess heat, and then releasing the heated water into the tower, where it is cooled down through evaporation before being recirculated.

Advantages:

1. Improved Efficiency: By maintaining consistent cooling, the cooling tower helps to ensure that the injection molding machine operates at peak efficiency, reducing downtime and preventing overheating of the system.

2. Energy Savings: Cooling towers are energy-efficient because they use water to cool down the machine, minimizing the need for energy-intensive cooling methods like air conditioning.

3. Increased Production Speed: Stable cooling conditions enable faster cycle times in the injection molding process, leading to higher throughput and improved productivity.

4. Extended Equipment Life: Consistent and effective cooling reduces the wear and tear on the machine’s components, leading to a longer lifespan for the injection molding machine and less frequent maintenance.

5. Cost-Effective: The use of cooling towers helps reduce energy consumption and extends the life of the equipment, which ultimately lowers operating costs.

6. Environmental Friendliness: Cooling towers use water in a closed-loop system, making them more environmentally friendly by reducing the consumption of other cooling agents and minimizing waste.

In conclusion, a cooling tower for injection molding machines is an indispensable component that ensures efficient cooling, improves production speed, reduces operational costs, and prolongs the lifespan of the equipment.

Product Parameters

| Model: | 50T |

| Flow rate: | 39.3m³/h |

| Air volume: | 330CMM |

| Appearance size: | Tower Height 2500mm, Diameter 1870mm |

| Weight: | 191kg |

| Fan diameter: | 880mm |

| Motor power: | 1.1kw |

| Water inlet diameter: | 80mm |

| Water outlet diameter: | 80mm |

FAQ

1. Are you manufacturer or trading company?

We are manufacturer,located in Ningbo,Zhejiang province.

2. What is the product range?

Focus on the manufacture and development of the molds, plastic injection molding machines, auxiliary equipment and system.

3. Where is your main selling market?

We have business in domestic,India,Indonesia,Egypt,Turkey,Uzbekistan,Russia etc.

4. Will you offer field installation and operator training at the buyer's factory?

Yes,we will arrange our skilled engineers for filed installation and training.

5. What is the delivery time?

For mold,it will be around 90days for production after getting confirmation of samples and drawings.

For injection molding machines will be ready around 60 days after getting mold size and prepayment.

For the auxiliary equipment like chiller, cooling tower etc, it will take around 15-20days after payment.

6. Do you also have source for raw material and spare parts?

Yes,we can offer with very competitive quality and reasonable price.

7. What is the standard of package?

Wooden case packing or standard export packing at the seller's options.

Full container shipment is highly suggest.

Product Description

Industrial 50T Water Cooling Tower

An injection molding machine cooling tower is a crucial component in the injection molding process, designed to maintain optimal temperature conditions for the machine and improve the overall efficiency of production. These cooling towers are used to cool down the circulating water or other cooling fluids that pass through the injection molding machine's cooling system.

Function:

The primary function of a cooling tower for injection molding machines is to dissipate the heat generated during the molding process. Injection molding machines operate at high temperatures, and maintaining a consistent, controlled temperature is essential for product quality and mold longevity. The cooling tower works by circulating water through the machine’s cooling channels, absorbing the excess heat, and then releasing the heated water into the tower, where it is cooled down through evaporation before being recirculated.

Advantages:

1. Improved Efficiency: By maintaining consistent cooling, the cooling tower helps to ensure that the injection molding machine operates at peak efficiency, reducing downtime and preventing overheating of the system.

2. Energy Savings: Cooling towers are energy-efficient because they use water to cool down the machine, minimizing the need for energy-intensive cooling methods like air conditioning.

3. Increased Production Speed: Stable cooling conditions enable faster cycle times in the injection molding process, leading to higher throughput and improved productivity.

4. Extended Equipment Life: Consistent and effective cooling reduces the wear and tear on the machine’s components, leading to a longer lifespan for the injection molding machine and less frequent maintenance.

5. Cost-Effective: The use of cooling towers helps reduce energy consumption and extends the life of the equipment, which ultimately lowers operating costs.

6. Environmental Friendliness: Cooling towers use water in a closed-loop system, making them more environmentally friendly by reducing the consumption of other cooling agents and minimizing waste.

In conclusion, a cooling tower for injection molding machines is an indispensable component that ensures efficient cooling, improves production speed, reduces operational costs, and prolongs the lifespan of the equipment.

Product Parameters

| Model: | 50T |

| Flow rate: | 39.3m³/h |

| Air volume: | 330CMM |

| Appearance size: | Tower Height 2500mm, Diameter 1870mm |

| Weight: | 191kg |

| Fan diameter: | 880mm |

| Motor power: | 1.1kw |

| Water inlet diameter: | 80mm |

| Water outlet diameter: | 80mm |

FAQ

1. Are you manufacturer or trading company?

We are manufacturer,located in Ningbo,Zhejiang province.

2. What is the product range?

Focus on the manufacture and development of the molds, plastic injection molding machines, auxiliary equipment and system.

3. Where is your main selling market?

We have business in domestic,India,Indonesia,Egypt,Turkey,Uzbekistan,Russia etc.

4. Will you offer field installation and operator training at the buyer's factory?

Yes,we will arrange our skilled engineers for filed installation and training.

5. What is the delivery time?

For mold,it will be around 90days for production after getting confirmation of samples and drawings.

For injection molding machines will be ready around 60 days after getting mold size and prepayment.

For the auxiliary equipment like chiller, cooling tower etc, it will take around 15-20days after payment.

6. Do you also have source for raw material and spare parts?

Yes,we can offer with very competitive quality and reasonable price.

7. What is the standard of package?

Wooden case packing or standard export packing at the seller's options.

Full container shipment is highly suggest.