Please Choose Your Language

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

NT580

LEANTALL

8477101090

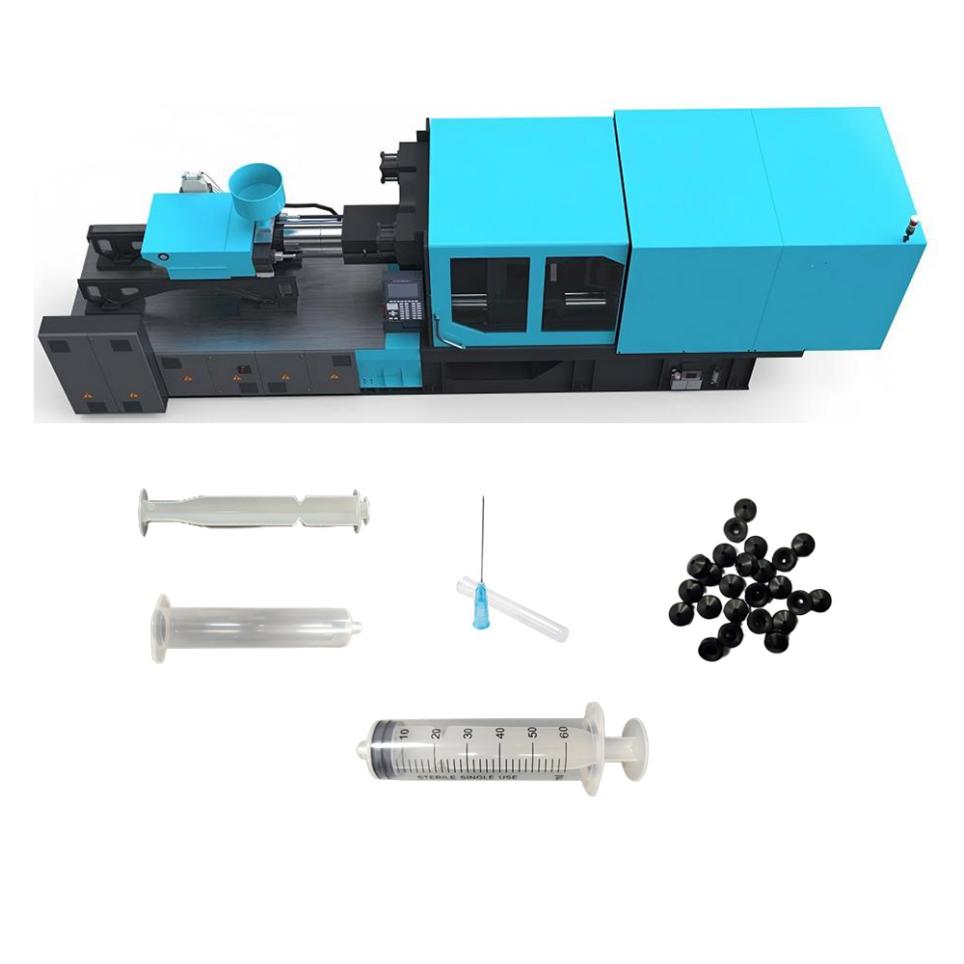

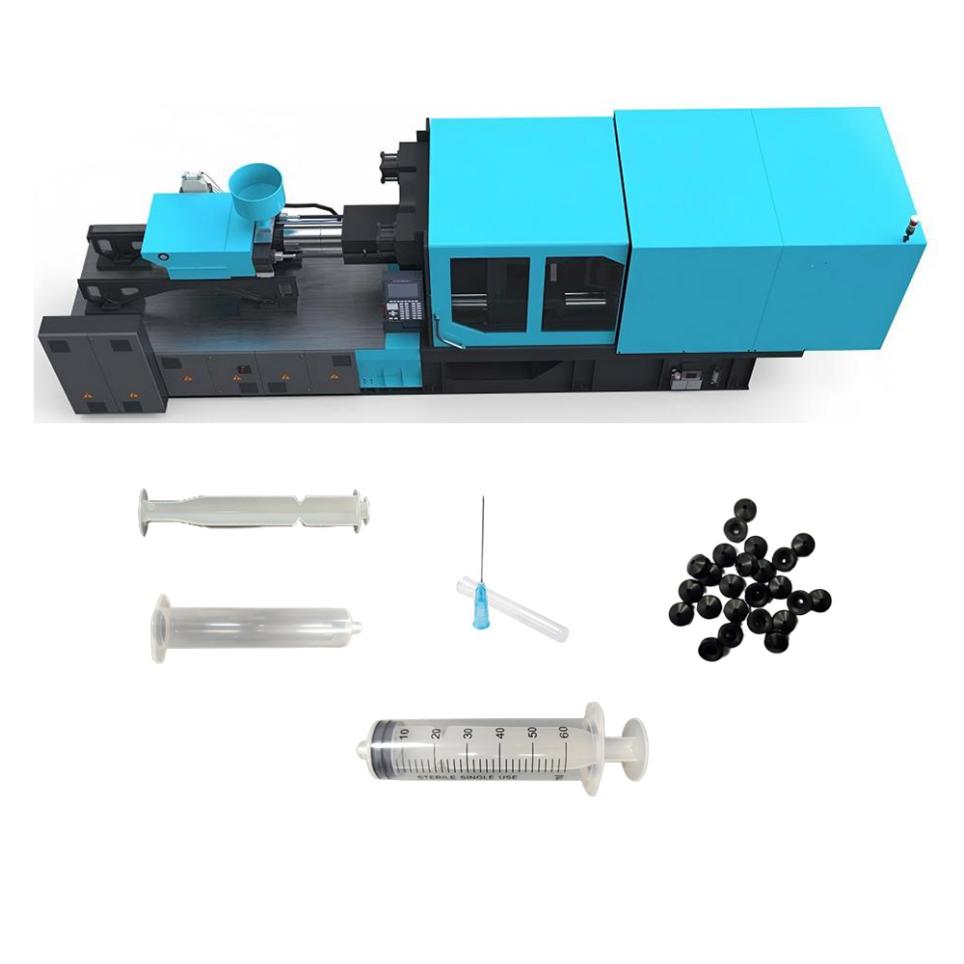

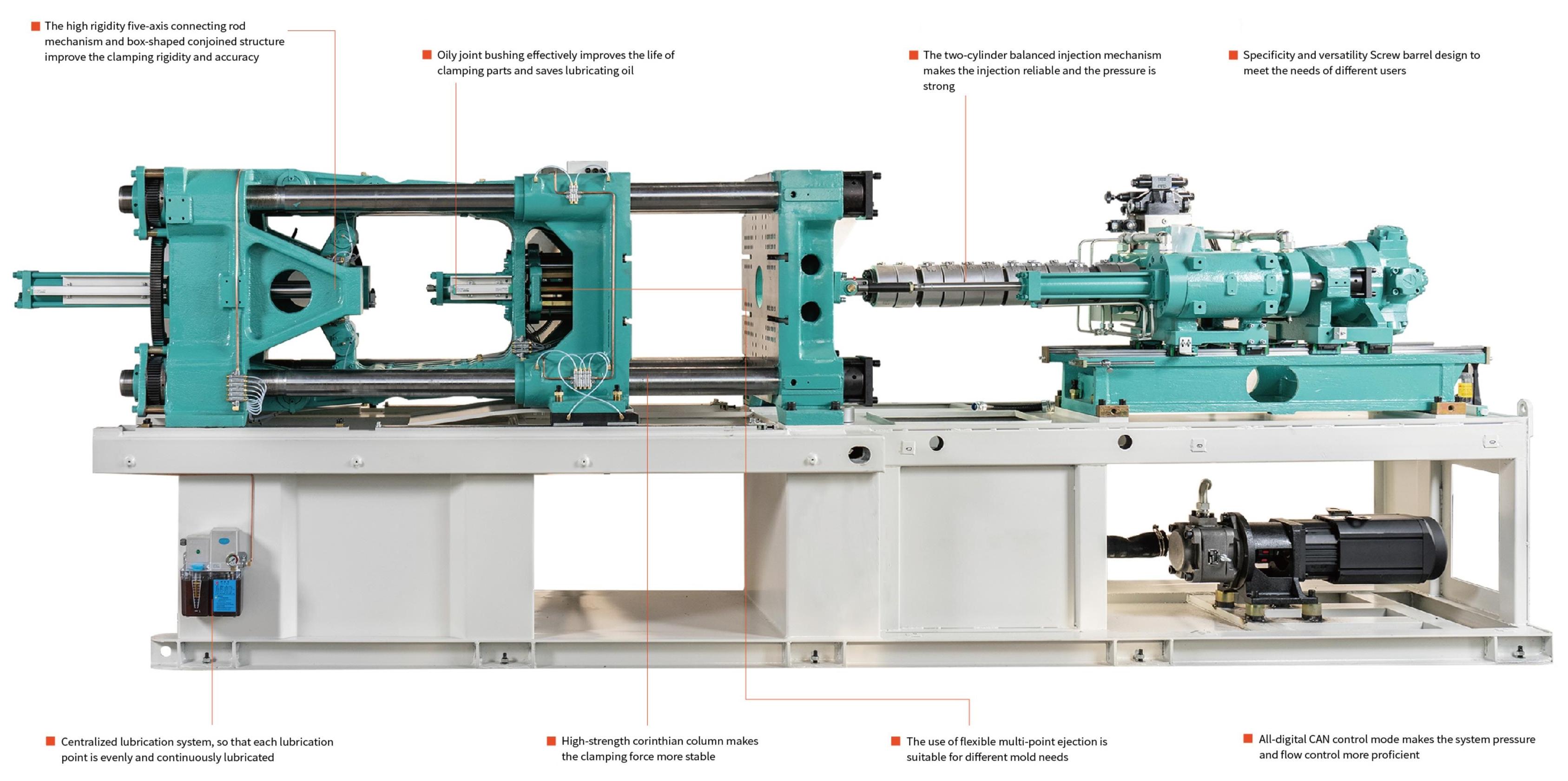

Injection molding machines capable of processing ABS, PVC, PP, PE, and PET provide manufacturers with the ability to produce a wide range of products using different types of plastics, each with unique properties suited for different applications.

Material Compatibility: These machines can be configured to handle a variety of thermoplastic materials, such as ABS (acrylonitrile butadiene styrene), PVC (polyvinyl chloride), PP (polypropylene), PE (polyethylene), and PET (polyethylene terephthalate).

High Precision and Versatility: These machines provide flexibility in producing different types of parts, whether they require high strength, chemical resistance, or clarity.

Advanced Control Systems: Optimized for each material, the machines offer advanced control over injection pressure, temperature, and cycle times, ensuring quality parts with minimal waste.

ABS: Used in automotive parts, appliance housings, and consumer products.

PVC: Common in pipes, window profiles, and electrical cable insulation.

PP: Used for packaging, medical devices, and automotive parts.

PE: Ideal for bottles, plastic bags, and containers.

PET: Common in beverage bottles, food packaging, and cosmetic containers.

These injection molding machines provide manufacturers with the flexibility to process a wide range of materials, ensuring versatility in production.

Technical Parameter | |||||

Part | Name | Unit | NT580 | ||

Injection unit | SCREW DIAMETER | mm | 80 | 85 | 90 |

SCREW L/D RATIO | L/D | 21.4 | 20 | 19 | |

SHOT VOLUME(THEORETICAL) | cm3 | 2010 | 2269 | 2544 | |

INJECTION WEIGHT(PS) | g | 1829 | 2064 | 2315 | |

INJECTION PRESSURE | Mpa | 174 | 154 | 137 | |

INJECTION RATE | cm⊃3;/sec | 517 | 584 | 655 | |

PLASTICZATION CAPACITY(PS) | g/sec | 93 | 110 | 133 | |

INJECTION STROKE | mm | 400 | |||

INJECTION SPEED | Mm/sec | 103 | |||

SCREW SPEED | rpm | 150 | |||

Clamping unit | CLAMP FORCE | Kn | 5800 | ||

OPEN STROKE | mm | 850 | |||

SPACE BETWEEN TIE BARS | mm×mm | 870X810 | |||

MAX.MOULD HEIGHT | mm | 830 | |||

MIN.MOULD HEIGHT | mm | 330 | |||

EJECTOR STROKE | mm | 235 | |||

EJECTOR FORCE | Kn | 152 | |||

EJECTOR NUMBER | N | 13 | |||

Others | MAX.PUMP PRESSURE | Mpa | 16 | ||

PUMP MOTOR POWER | Kw | 65 | |||

HEATING POWER | Kw | 33.5 | |||

MACHINE DIMENSION(L*W*H) | m×m×m | 8.6*2.3*2.6 | |||

MACHINE WEIGHT(ESTIMATE) | T | 20 | |||

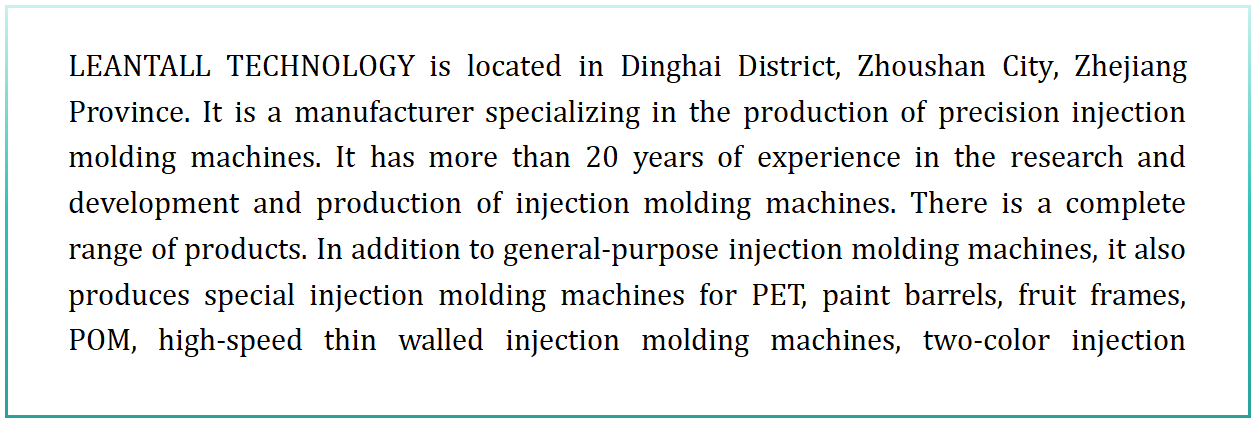

1. Q: What is the product range?

A: Focus on the manufacture and development of plastic injection molding machines and its auxiliary equipment such as cooling tower, chiller, etc.

2. Q: Where is your main selling market?

A: We have business domestic, USA, Russia, Indonesia, Egypt, Turkey, Uzbekistan, Pakistan, etc.

3. Q: Will you offer field installation and operator training at the buyer's factory?

A: Yes, we will arrange our skilled engineers for filed installation and training.

4. Q: What is the delivery time(equipment production time)?

A: It will be ready around 50-75 days after getting mutual confirmation about the order details and prepayment.

5. Q: Do you also have source for molds and spare parts?

A: Yes, we can offer with the competitive quality and reasonable price. Customized as required.

6. Q: What is the standard of package?

A: Wooden case packing for the auxiliary equipment, bare packing for the plastic injection molding machine. Full container shipment is highly suggest.

Injection molding machines capable of processing ABS, PVC, PP, PE, and PET provide manufacturers with the ability to produce a wide range of products using different types of plastics, each with unique properties suited for different applications.

Material Compatibility: These machines can be configured to handle a variety of thermoplastic materials, such as ABS (acrylonitrile butadiene styrene), PVC (polyvinyl chloride), PP (polypropylene), PE (polyethylene), and PET (polyethylene terephthalate).

High Precision and Versatility: These machines provide flexibility in producing different types of parts, whether they require high strength, chemical resistance, or clarity.

Advanced Control Systems: Optimized for each material, the machines offer advanced control over injection pressure, temperature, and cycle times, ensuring quality parts with minimal waste.

ABS: Used in automotive parts, appliance housings, and consumer products.

PVC: Common in pipes, window profiles, and electrical cable insulation.

PP: Used for packaging, medical devices, and automotive parts.

PE: Ideal for bottles, plastic bags, and containers.

PET: Common in beverage bottles, food packaging, and cosmetic containers.

These injection molding machines provide manufacturers with the flexibility to process a wide range of materials, ensuring versatility in production.

Technical Parameter | |||||

Part | Name | Unit | NT580 | ||

Injection unit | SCREW DIAMETER | mm | 80 | 85 | 90 |

SCREW L/D RATIO | L/D | 21.4 | 20 | 19 | |

SHOT VOLUME(THEORETICAL) | cm3 | 2010 | 2269 | 2544 | |

INJECTION WEIGHT(PS) | g | 1829 | 2064 | 2315 | |

INJECTION PRESSURE | Mpa | 174 | 154 | 137 | |

INJECTION RATE | cm⊃3;/sec | 517 | 584 | 655 | |

PLASTICZATION CAPACITY(PS) | g/sec | 93 | 110 | 133 | |

INJECTION STROKE | mm | 400 | |||

INJECTION SPEED | Mm/sec | 103 | |||

SCREW SPEED | rpm | 150 | |||

Clamping unit | CLAMP FORCE | Kn | 5800 | ||

OPEN STROKE | mm | 850 | |||

SPACE BETWEEN TIE BARS | mm×mm | 870X810 | |||

MAX.MOULD HEIGHT | mm | 830 | |||

MIN.MOULD HEIGHT | mm | 330 | |||

EJECTOR STROKE | mm | 235 | |||

EJECTOR FORCE | Kn | 152 | |||

EJECTOR NUMBER | N | 13 | |||

Others | MAX.PUMP PRESSURE | Mpa | 16 | ||

PUMP MOTOR POWER | Kw | 65 | |||

HEATING POWER | Kw | 33.5 | |||

MACHINE DIMENSION(L*W*H) | m×m×m | 8.6*2.3*2.6 | |||

MACHINE WEIGHT(ESTIMATE) | T | 20 | |||

1. Q: What is the product range?

A: Focus on the manufacture and development of plastic injection molding machines and its auxiliary equipment such as cooling tower, chiller, etc.

2. Q: Where is your main selling market?

A: We have business domestic, USA, Russia, Indonesia, Egypt, Turkey, Uzbekistan, Pakistan, etc.

3. Q: Will you offer field installation and operator training at the buyer's factory?

A: Yes, we will arrange our skilled engineers for filed installation and training.

4. Q: What is the delivery time(equipment production time)?

A: It will be ready around 50-75 days after getting mutual confirmation about the order details and prepayment.

5. Q: Do you also have source for molds and spare parts?

A: Yes, we can offer with the competitive quality and reasonable price. Customized as required.

6. Q: What is the standard of package?

A: Wooden case packing for the auxiliary equipment, bare packing for the plastic injection molding machine. Full container shipment is highly suggest.