Please Choose Your Language

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

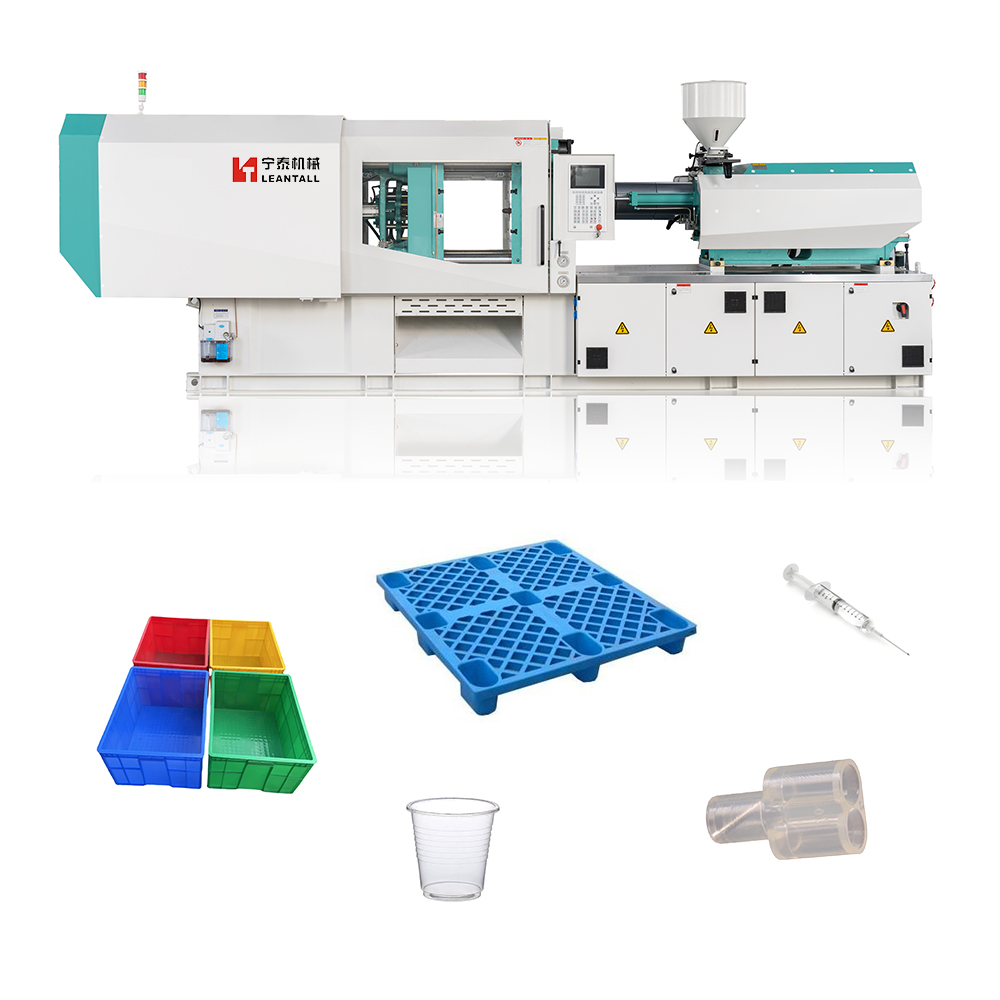

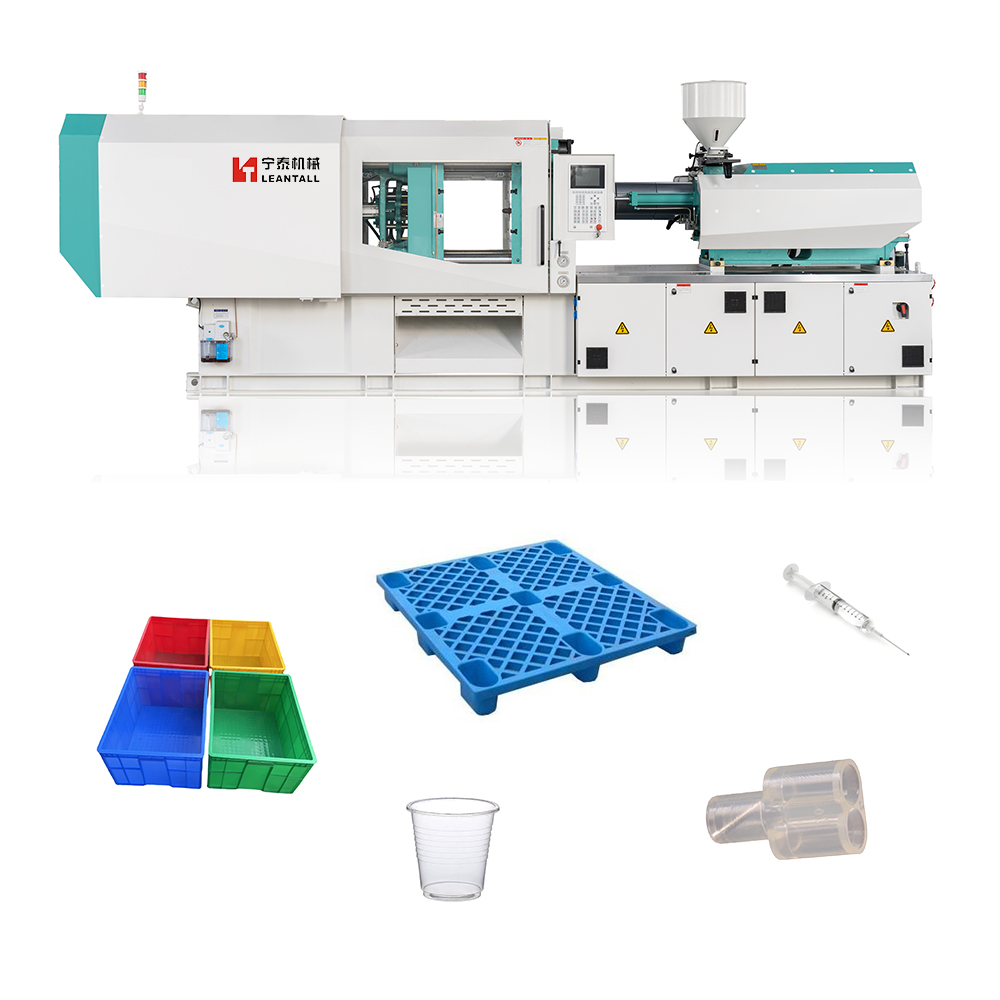

NT280

LEANTALL

8477101090

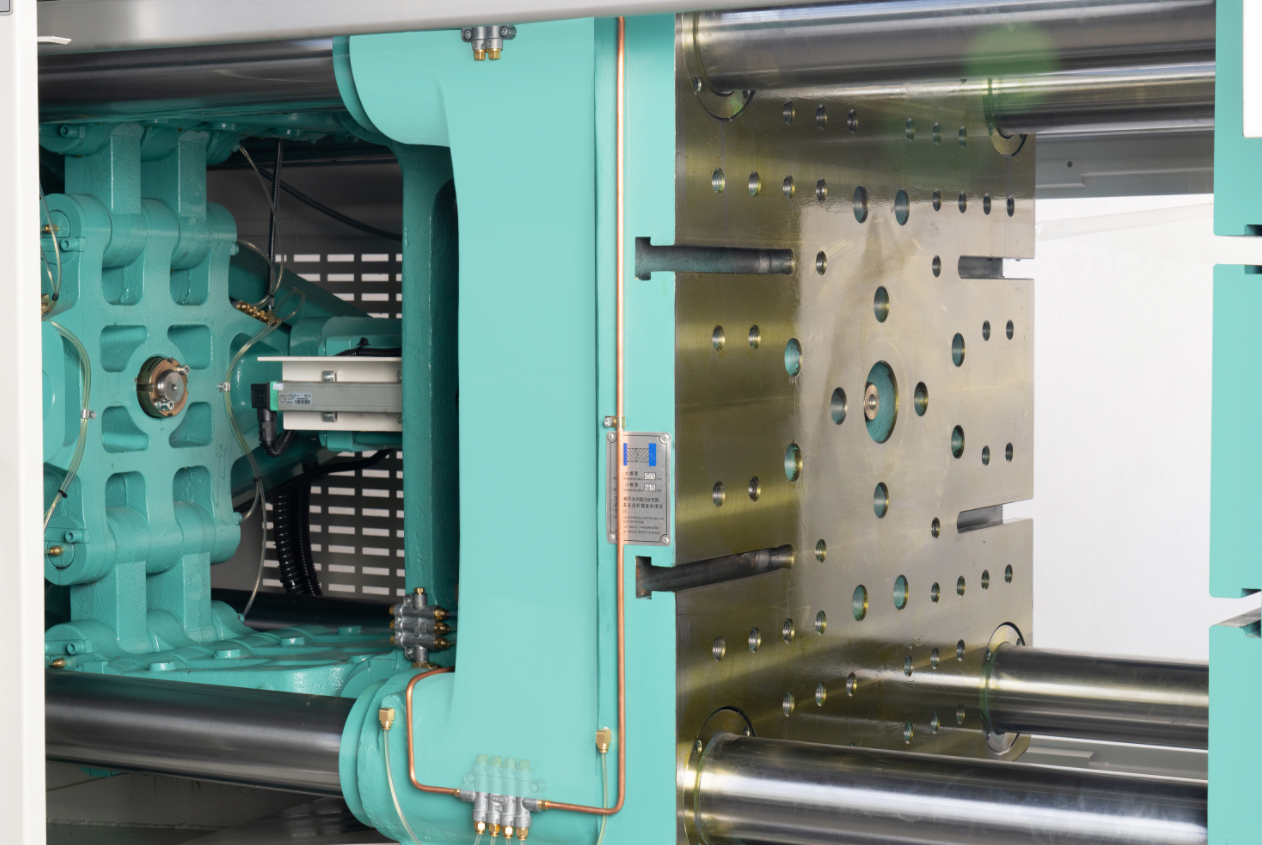

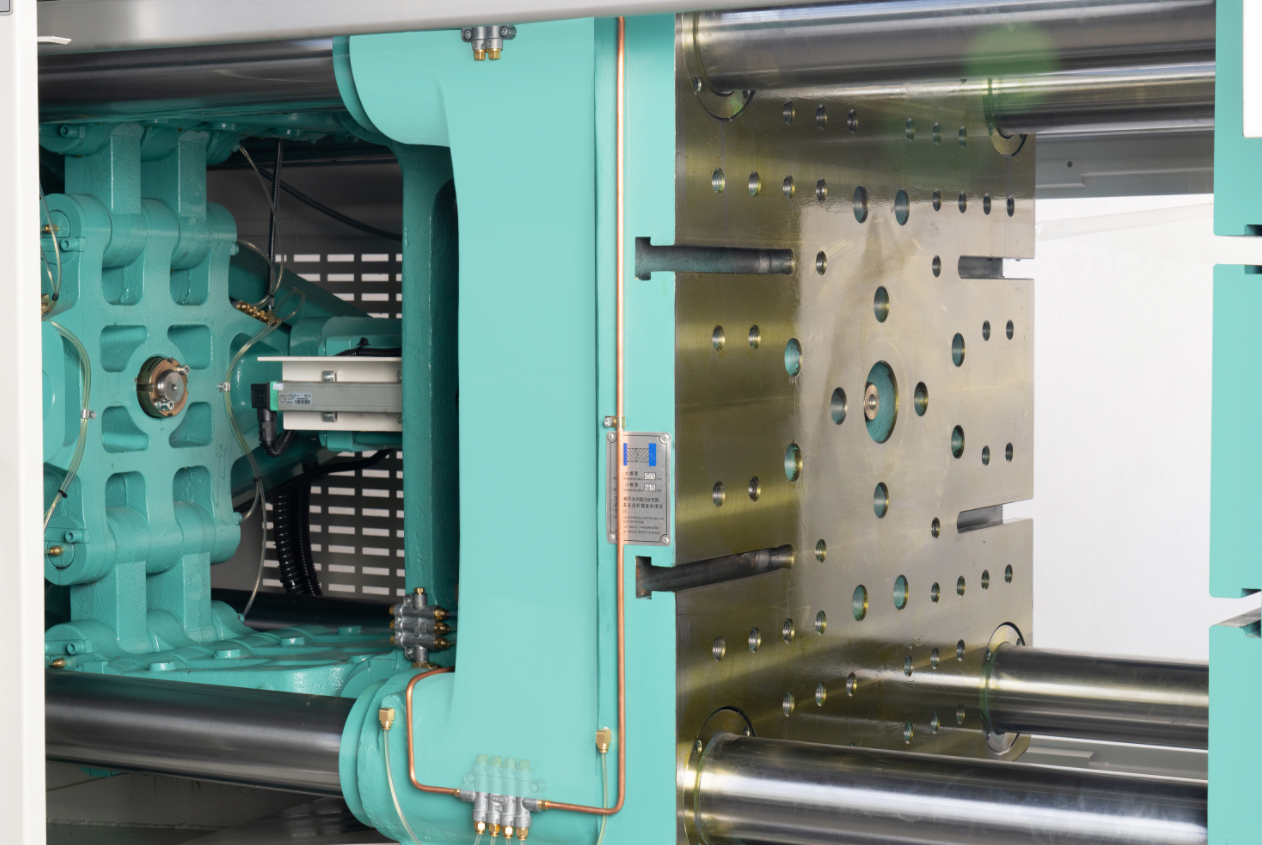

CLAMPING UNIT

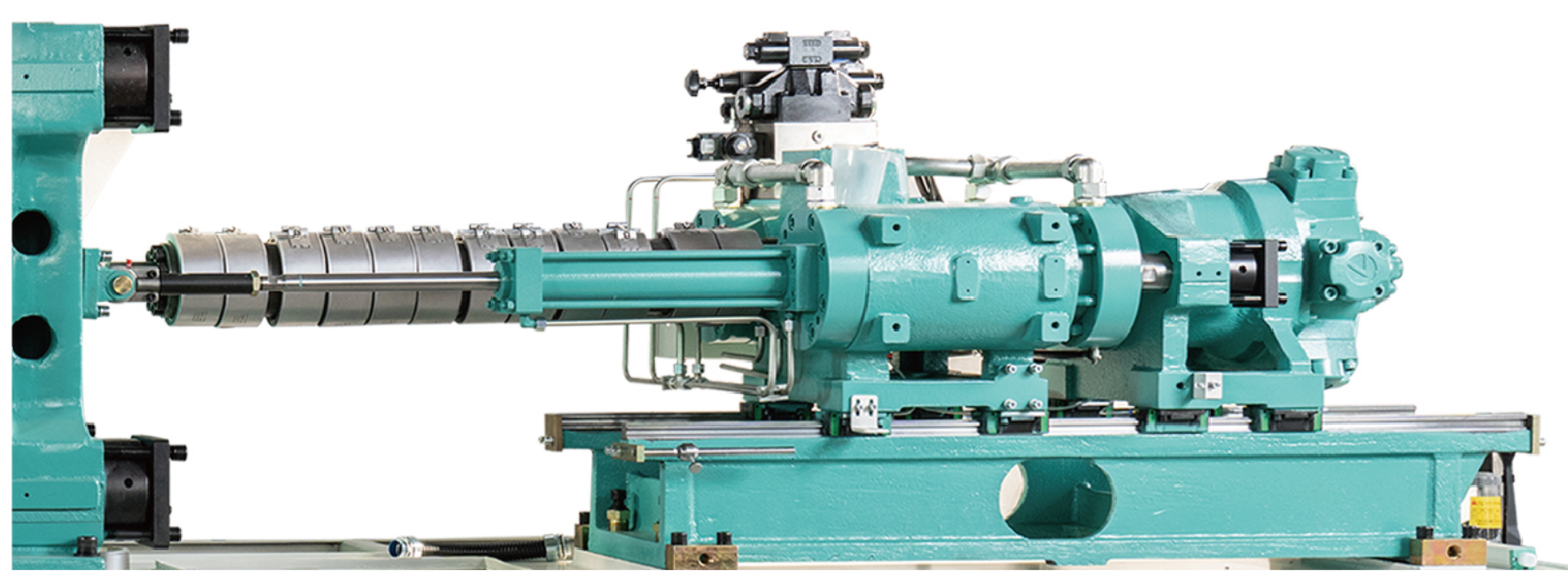

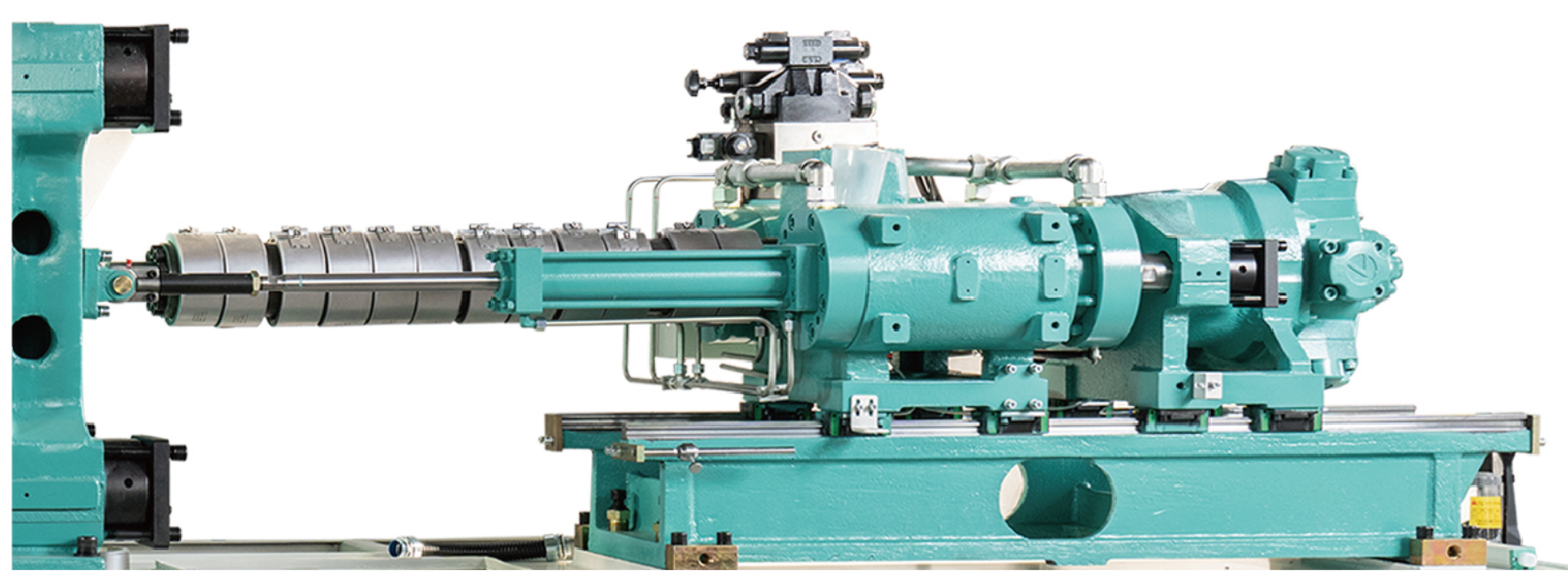

INJECTION UNIT

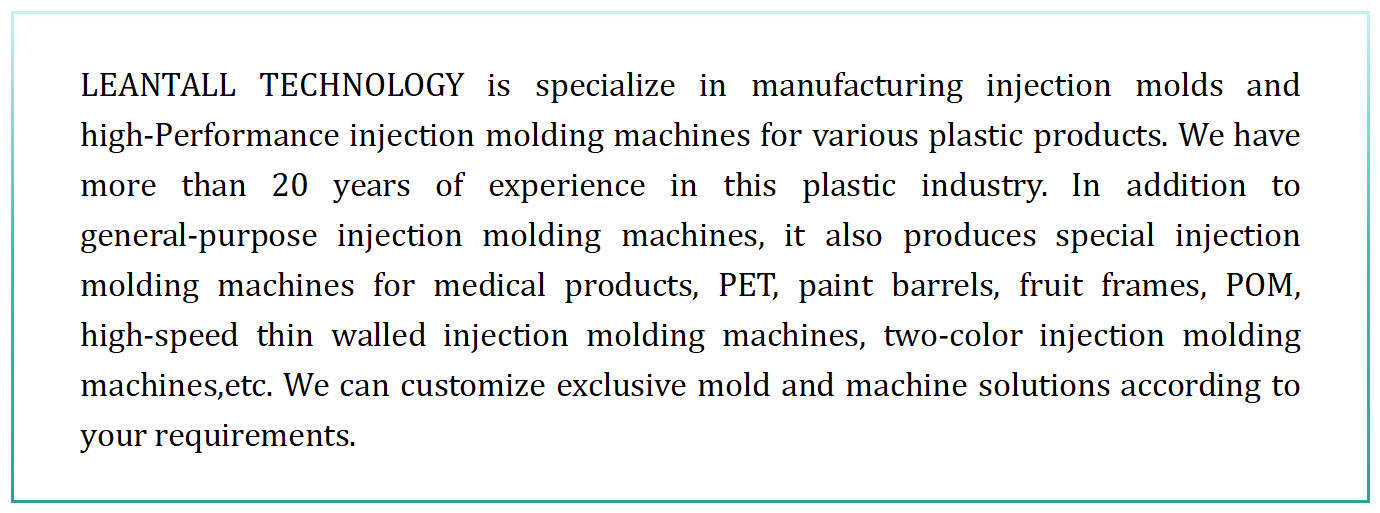

As sustainability becomes a key focus for manufacturers, energy-saving injection molding machines are helping companies reduce their carbon footprint and lower operational costs.

Hybrid Drive Systems: These machines often combine hydraulic, electric, and servo technologies to optimize energy use based on the specific molding requirements. For example, they may use hydraulics for high-power functions and electric drives for precision movements, switching seamlessly between them to save energy.

Energy Recovery Systems: Advanced energy recovery systems capture and reuse energy that would otherwise be wasted, such as the heat generated during the injection process. This significantly reduces the overall energy consumption of the machine.

Automated Monitoring: These machines often come with automated systems that monitor energy usage in real time, providing data to manufacturers about how to optimize processes further for energy savings.

Automotive and Packaging Industries: Reducing operational costs in industries that rely on high-volume production.

Sustainability-Focused Manufacturing: Suitable for companies that are looking to meet environmental goals while maintaining competitive pricing.

The evolution of injection molding technology has resulted in the development of specialized machines that cater to the unique needs of various industries. From energy-efficient solutions to highly precise medical applications, these machines are helping manufacturers meet growing demands for quality, speed, and sustainability. With continued innovation, we can expect to see even more advanced injection molding machines that push the boundaries of what’s possible in manufacturing, ultimately shaping the future of production across diverse sectors.

Technical Parameter | |||||

Part | Name | Unit | NT280 | ||

Injection unit | SCREW DIAMETER | mm | 55 | 60 | 65 |

SCREW L/D RATIO | L/D | 22 | 20 | 18.3 | |

SHOT VOLUME(THEORETICAL) | CM3 | 677 | 805 | 945 | |

INJECTION WEIGHT(PS) | g | 616 | 732 | 860 | |

INJECTION PRESSURE | Mpa | 200 | 168 | 143 | |

INJECTION RATE | cm⊃3;/sec | 266 | 316 | 371 | |

PLASTICZATION CAPACITY(PS) | g/sec | 48 | 56 | 71 | |

INJECTION STROKE | mm | 285 | |||

INJECTION SPEED | Mm/sec | 112 | |||

SCREW SPEED | rpm | 210 | |||

Clamping unit | CLAMP FORCE | Kn | 2800 | ||

OPEN STROKE | mm | 590 | |||

SPACE BETWEEN TIE BARS | mm×mm | 630X580 | |||

MAX.MOULD HEIGHT | mm | 570 | |||

MIN.MOULD HEIGHT | mm | 190 | |||

EJECTOR STROKE | mm | 160 | |||

EJECTOR FORCE | Kn | 101 | |||

EJECTOR NUMBER | N | 13 | |||

Others | MAX.PUMP PRESSURE | Mpa | 16 | ||

PUMP MOTOR POWER | Kw | 39 | |||

HEATING POWER | Kw | 18.5 | |||

MACHINE DIMENSION(L*W*H) | m×m×m | 6.2*1.6*2.35 | |||

MACHINE WEIGHT(ESTIMATE) | T | 8.8 | |||

1. Q: What is the product range?

A: Focus on the manufacture and development of plastic injection molding machines and its auxiliary equipment such as cooling tower, chiller, etc.

2. Q: Where is your main selling market?

A: We have business domestic, USA, Russia, Indonesia, Egypt, Turkey, Uzbekistan, Pakistan, etc.

3. Q: Will you offer field installation and operator training at the buyer's factory?

A: Yes, we will arrange our skilled engineers for filed installation and training.

4. Q: What is the delivery time(equipment production time)?

A: It will be ready around 50-75 days after getting mutual confirmation about the order details and prepayment.

5. Q: Do you also have source for molds and spare parts?

A: Yes, we can offer with the competitive quality and reasonable price. Customized as required.

6. Q: What is the standard of package?

A: Wooden case packing for the auxiliary equipment, bare packing for the plastic injection molding machine. Full container shipment is highly suggest.

CLAMPING UNIT

INJECTION UNIT

As sustainability becomes a key focus for manufacturers, energy-saving injection molding machines are helping companies reduce their carbon footprint and lower operational costs.

Hybrid Drive Systems: These machines often combine hydraulic, electric, and servo technologies to optimize energy use based on the specific molding requirements. For example, they may use hydraulics for high-power functions and electric drives for precision movements, switching seamlessly between them to save energy.

Energy Recovery Systems: Advanced energy recovery systems capture and reuse energy that would otherwise be wasted, such as the heat generated during the injection process. This significantly reduces the overall energy consumption of the machine.

Automated Monitoring: These machines often come with automated systems that monitor energy usage in real time, providing data to manufacturers about how to optimize processes further for energy savings.

Automotive and Packaging Industries: Reducing operational costs in industries that rely on high-volume production.

Sustainability-Focused Manufacturing: Suitable for companies that are looking to meet environmental goals while maintaining competitive pricing.

The evolution of injection molding technology has resulted in the development of specialized machines that cater to the unique needs of various industries. From energy-efficient solutions to highly precise medical applications, these machines are helping manufacturers meet growing demands for quality, speed, and sustainability. With continued innovation, we can expect to see even more advanced injection molding machines that push the boundaries of what’s possible in manufacturing, ultimately shaping the future of production across diverse sectors.

Technical Parameter | |||||

Part | Name | Unit | NT280 | ||

Injection unit | SCREW DIAMETER | mm | 55 | 60 | 65 |

SCREW L/D RATIO | L/D | 22 | 20 | 18.3 | |

SHOT VOLUME(THEORETICAL) | CM3 | 677 | 805 | 945 | |

INJECTION WEIGHT(PS) | g | 616 | 732 | 860 | |

INJECTION PRESSURE | Mpa | 200 | 168 | 143 | |

INJECTION RATE | cm⊃3;/sec | 266 | 316 | 371 | |

PLASTICZATION CAPACITY(PS) | g/sec | 48 | 56 | 71 | |

INJECTION STROKE | mm | 285 | |||

INJECTION SPEED | Mm/sec | 112 | |||

SCREW SPEED | rpm | 210 | |||

Clamping unit | CLAMP FORCE | Kn | 2800 | ||

OPEN STROKE | mm | 590 | |||

SPACE BETWEEN TIE BARS | mm×mm | 630X580 | |||

MAX.MOULD HEIGHT | mm | 570 | |||

MIN.MOULD HEIGHT | mm | 190 | |||

EJECTOR STROKE | mm | 160 | |||

EJECTOR FORCE | Kn | 101 | |||

EJECTOR NUMBER | N | 13 | |||

Others | MAX.PUMP PRESSURE | Mpa | 16 | ||

PUMP MOTOR POWER | Kw | 39 | |||

HEATING POWER | Kw | 18.5 | |||

MACHINE DIMENSION(L*W*H) | m×m×m | 6.2*1.6*2.35 | |||

MACHINE WEIGHT(ESTIMATE) | T | 8.8 | |||

1. Q: What is the product range?

A: Focus on the manufacture and development of plastic injection molding machines and its auxiliary equipment such as cooling tower, chiller, etc.

2. Q: Where is your main selling market?

A: We have business domestic, USA, Russia, Indonesia, Egypt, Turkey, Uzbekistan, Pakistan, etc.

3. Q: Will you offer field installation and operator training at the buyer's factory?

A: Yes, we will arrange our skilled engineers for filed installation and training.

4. Q: What is the delivery time(equipment production time)?

A: It will be ready around 50-75 days after getting mutual confirmation about the order details and prepayment.

5. Q: Do you also have source for molds and spare parts?

A: Yes, we can offer with the competitive quality and reasonable price. Customized as required.

6. Q: What is the standard of package?

A: Wooden case packing for the auxiliary equipment, bare packing for the plastic injection molding machine. Full container shipment is highly suggest.