Please Choose Your Language

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

NT360

LEANTALL

8477101090

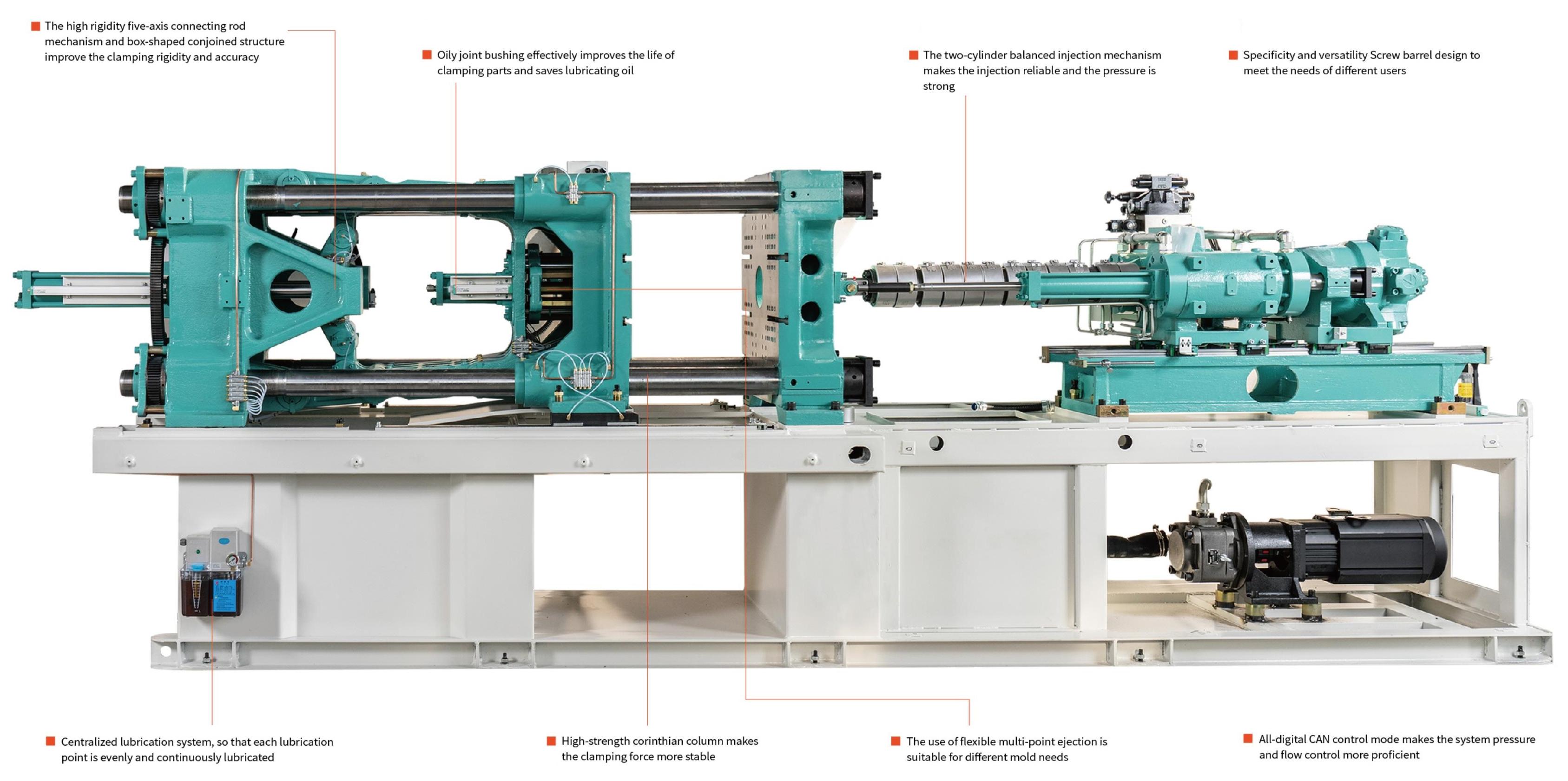

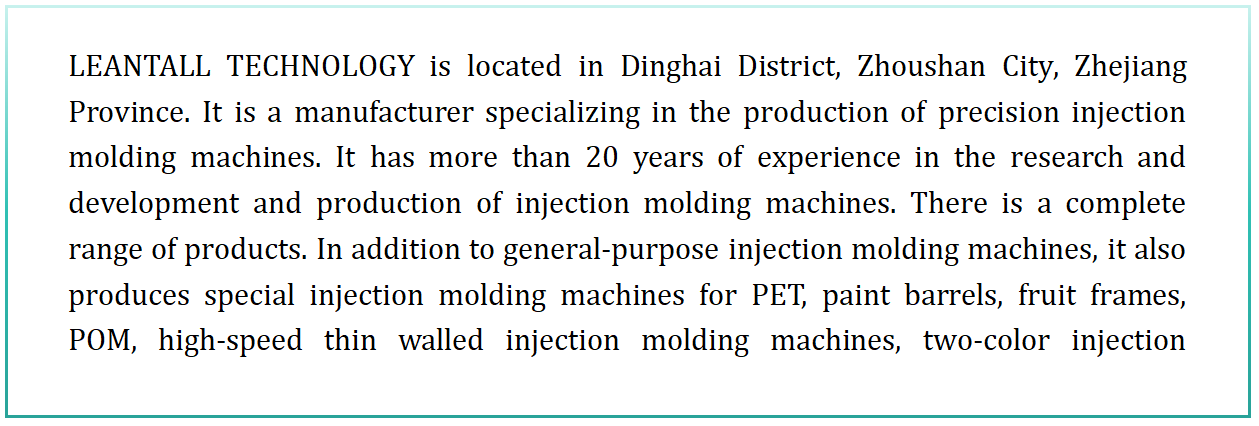

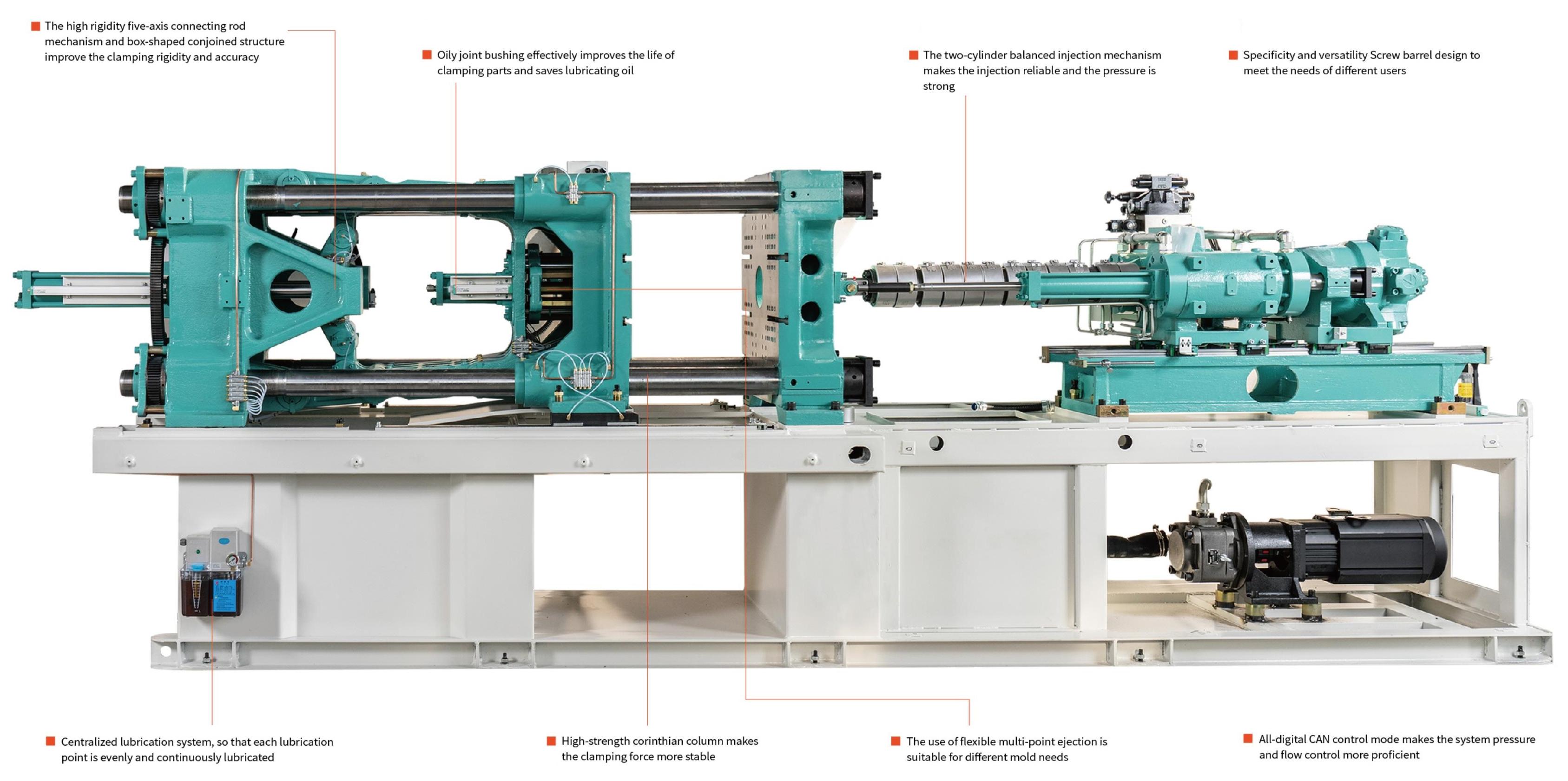

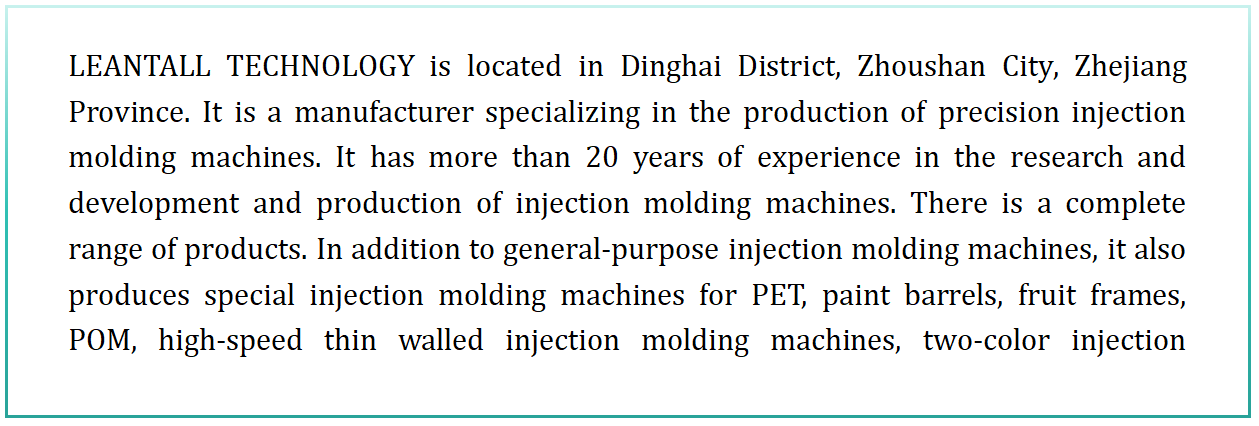

Plastic injection molding equipment consists of plasticizing system, injection system, the clamping system and transmission system. Our company has been applying die casting technologies to injection moulding machines for many years, like in mechanical, hydraulic, electric control, etc for comprehensive improvement, perfect combination of dynamic pressure casting and speed.

In order to improve the production stability and energy saving of medical products such as syringes, our company especially added infrared heating coil and servo motor system on the standard injection molding machine.

Technical Parameter | |||||

Part | Name | Unit | NT360 | ||

Injection unit | SCREW DIAMETER | mm | 65 | 70 | 75 |

SCREW L/D RATIO | L/D | 22 | 20 | 19 | |

SHOT VOLUME(THEORETICAL) | cm3 | 1161 | 1347 | 1546 | |

INJECTION WEIGHT(PS) | g | 1056 | 1225 | 1406 | |

INJECTION PRESSURE | Mpa | 202 | 174 | 152 | |

INJECTION RATE | cm⊃3;/sec | 328 | 380 | 437 | |

PLASTICZATION CAPACITY(PS) | g/sec | 63 | 76 | 93 | |

INJECTION STROKE | mm | 350 | |||

INJECTION SPEED | Mm/sec | 99 | |||

SCREW SPEED | rpm | 180 | |||

Clamping unit | CLAMP FORCE | Kn | 3600 | ||

OPEN STROKE | mm | 670 | |||

SPACE BETWEEN TIE BARS | mm×mm | 730X680 | |||

MAX.MOULD HEIGHT | mm | 700 | |||

MIN.MOULD HEIGHT | mm | 250 | |||

EJECTOR STROKE | mm | 195 | |||

EJECTOR FORCE | Kn | 101 | |||

EJECTOR NUMBER | N | 13 | |||

Others | MAX.PUMP PRESSURE | Mpa | 16 | ||

PUMP MOTOR POWER | Kw | 44 | |||

HEATING POWER | Kw | 22.5 | |||

MACHINE DIMENSION(L*W*H) | m×m×m | 7.2*1.85*2.35 | |||

MACHINE WEIGHT(ESTIMATE) | T | 11 | |||

1. Q: What is the product range?

A: Focus on the manufacture and development of plastic injection molding machines and its auxiliary equipment such as cooling tower, chiller, etc.

2. Q: Where is your main selling market?

A: We have business domestic, USA, Russia, Indonesia, Egypt, Turkey, Uzbekistan, Pakistan, etc.

3. Q: Will you offer field installation and operator training at the buyer's factory?

A: Yes, we will arrange our skilled engineers for filed installation and training.

4. Q: What is the delivery time(equipment production time)?

A: It will be ready around 50-75 days after getting mutual confirmation about the order details and prepayment.

5. Q: Do you also have source for molds and spare parts?

A: Yes, we can offer with the competitive quality and reasonable price. Customized as required.

6. Q: What is the standard of package?

A: Wooden case packing for the auxiliary equipment, bare packing for the plastic injection molding machine. Full container shipment is highly suggest.

Plastic injection molding equipment consists of plasticizing system, injection system, the clamping system and transmission system. Our company has been applying die casting technologies to injection moulding machines for many years, like in mechanical, hydraulic, electric control, etc for comprehensive improvement, perfect combination of dynamic pressure casting and speed.

In order to improve the production stability and energy saving of medical products such as syringes, our company especially added infrared heating coil and servo motor system on the standard injection molding machine.

Technical Parameter | |||||

Part | Name | Unit | NT360 | ||

Injection unit | SCREW DIAMETER | mm | 65 | 70 | 75 |

SCREW L/D RATIO | L/D | 22 | 20 | 19 | |

SHOT VOLUME(THEORETICAL) | cm3 | 1161 | 1347 | 1546 | |

INJECTION WEIGHT(PS) | g | 1056 | 1225 | 1406 | |

INJECTION PRESSURE | Mpa | 202 | 174 | 152 | |

INJECTION RATE | cm⊃3;/sec | 328 | 380 | 437 | |

PLASTICZATION CAPACITY(PS) | g/sec | 63 | 76 | 93 | |

INJECTION STROKE | mm | 350 | |||

INJECTION SPEED | Mm/sec | 99 | |||

SCREW SPEED | rpm | 180 | |||

Clamping unit | CLAMP FORCE | Kn | 3600 | ||

OPEN STROKE | mm | 670 | |||

SPACE BETWEEN TIE BARS | mm×mm | 730X680 | |||

MAX.MOULD HEIGHT | mm | 700 | |||

MIN.MOULD HEIGHT | mm | 250 | |||

EJECTOR STROKE | mm | 195 | |||

EJECTOR FORCE | Kn | 101 | |||

EJECTOR NUMBER | N | 13 | |||

Others | MAX.PUMP PRESSURE | Mpa | 16 | ||

PUMP MOTOR POWER | Kw | 44 | |||

HEATING POWER | Kw | 22.5 | |||

MACHINE DIMENSION(L*W*H) | m×m×m | 7.2*1.85*2.35 | |||

MACHINE WEIGHT(ESTIMATE) | T | 11 | |||

1. Q: What is the product range?

A: Focus on the manufacture and development of plastic injection molding machines and its auxiliary equipment such as cooling tower, chiller, etc.

2. Q: Where is your main selling market?

A: We have business domestic, USA, Russia, Indonesia, Egypt, Turkey, Uzbekistan, Pakistan, etc.

3. Q: Will you offer field installation and operator training at the buyer's factory?

A: Yes, we will arrange our skilled engineers for filed installation and training.

4. Q: What is the delivery time(equipment production time)?

A: It will be ready around 50-75 days after getting mutual confirmation about the order details and prepayment.

5. Q: Do you also have source for molds and spare parts?

A: Yes, we can offer with the competitive quality and reasonable price. Customized as required.

6. Q: What is the standard of package?

A: Wooden case packing for the auxiliary equipment, bare packing for the plastic injection molding machine. Full container shipment is highly suggest.