Please Choose Your Language

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

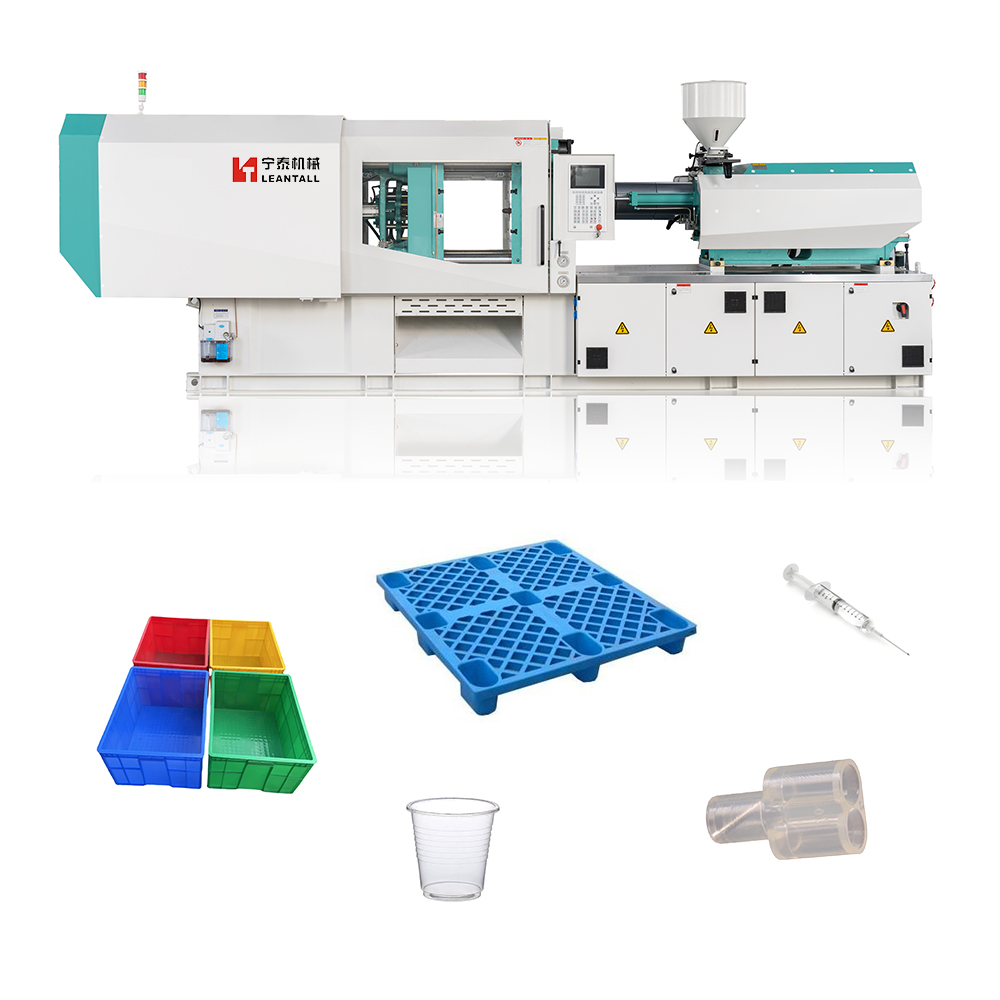

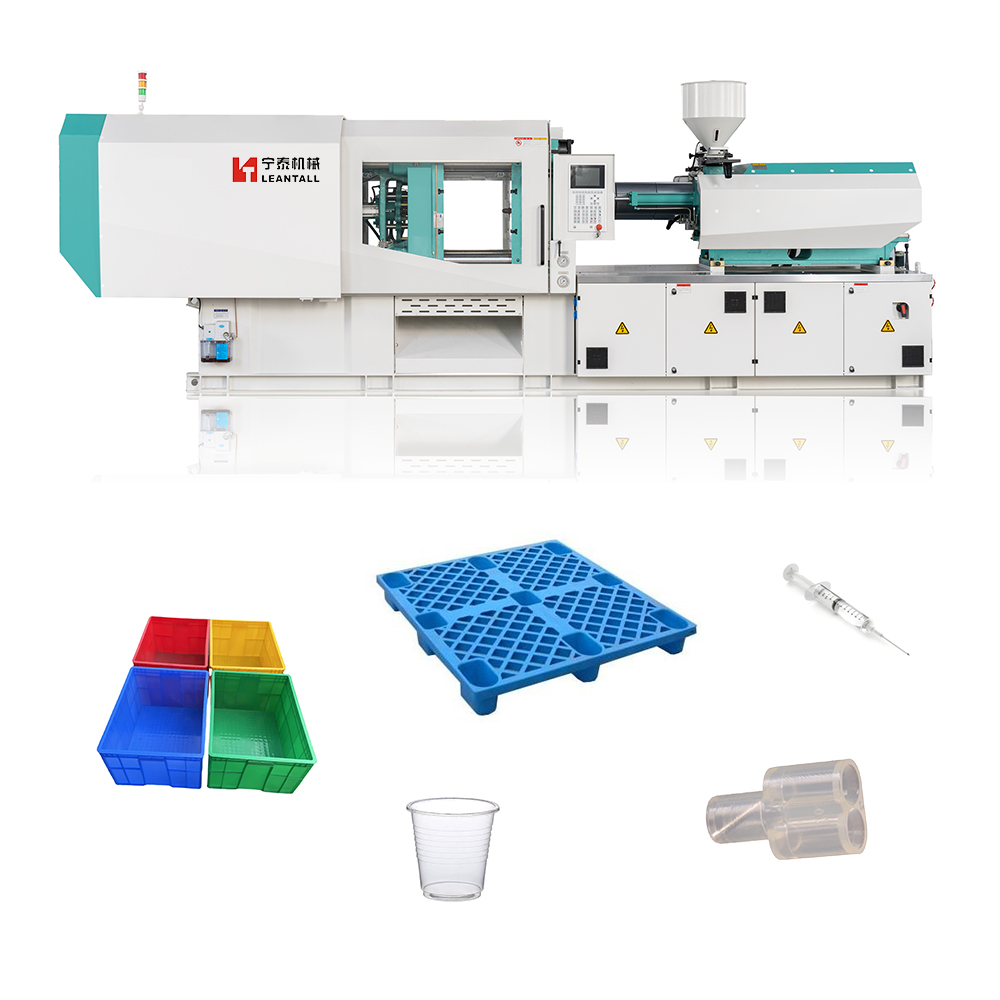

NT280

LEANTALL

8477101090

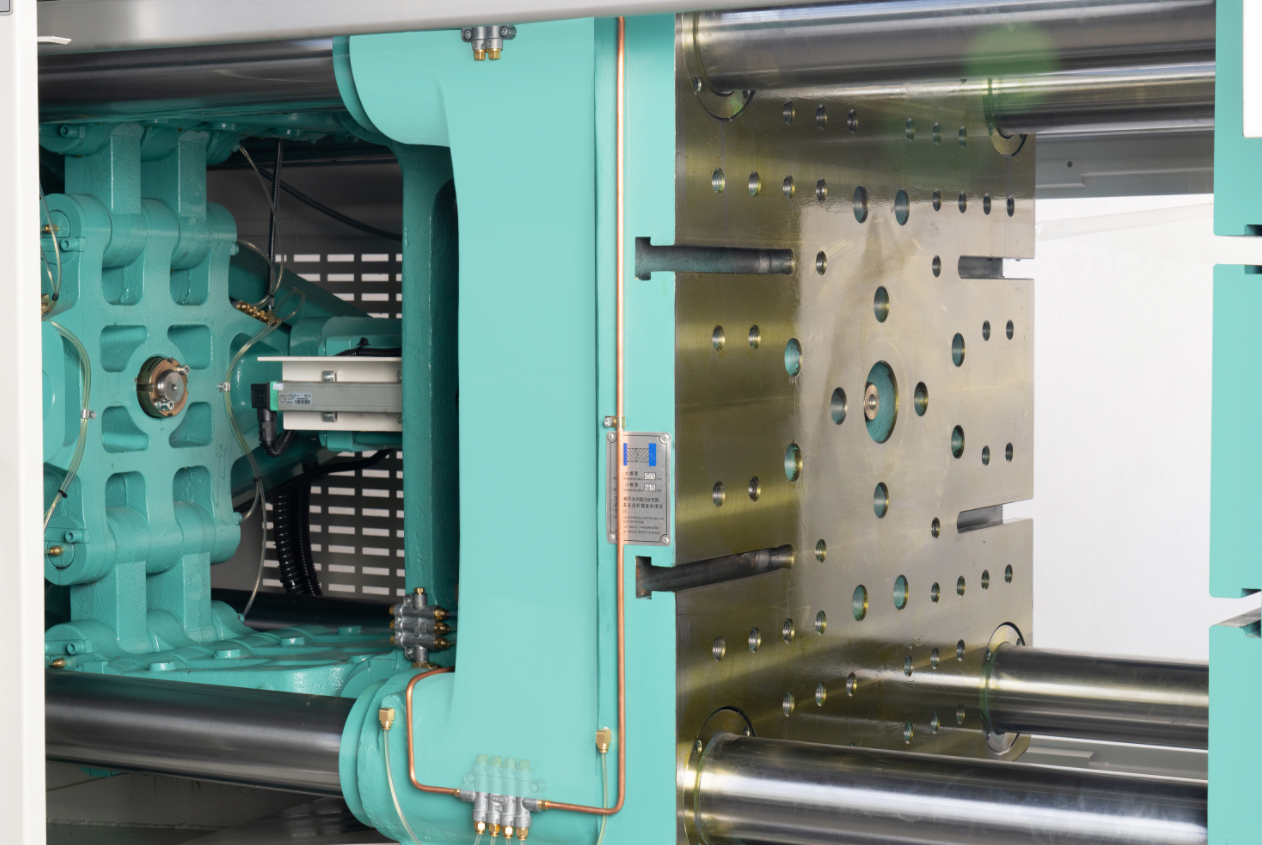

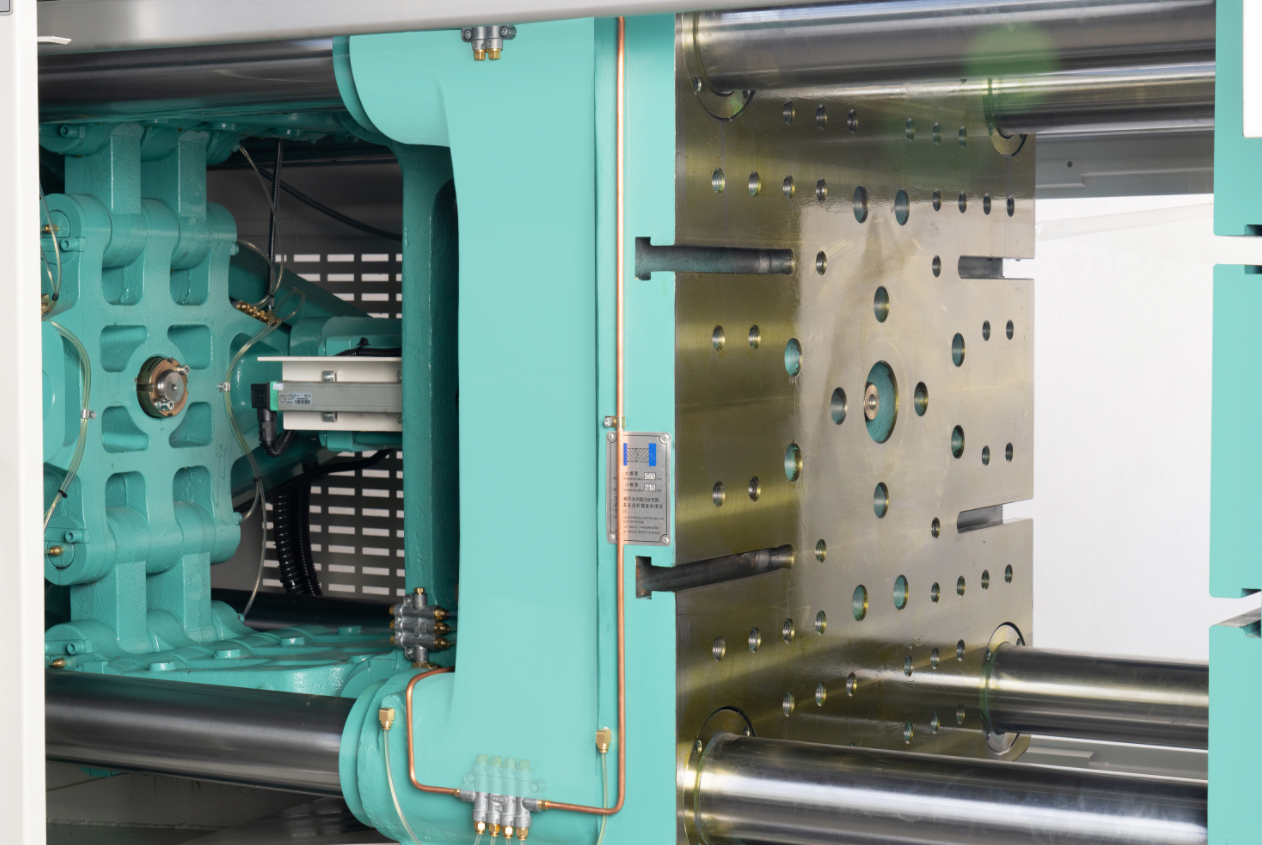

CLAMPING UNIT

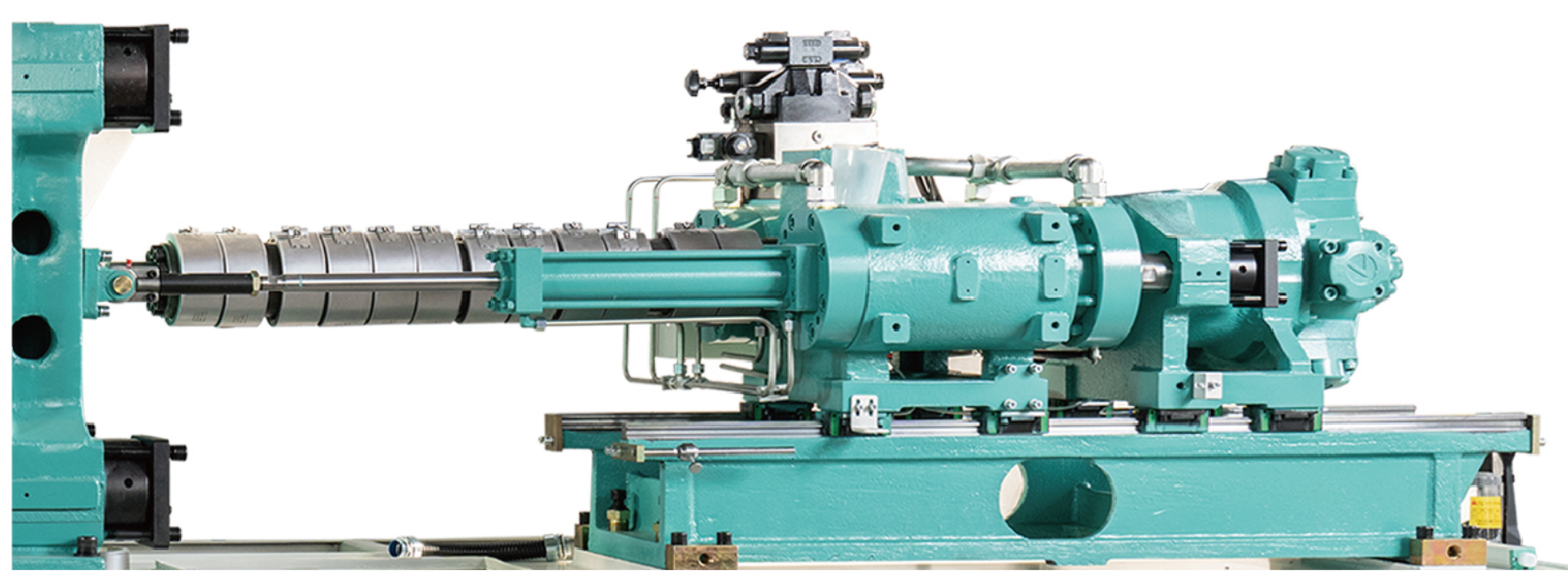

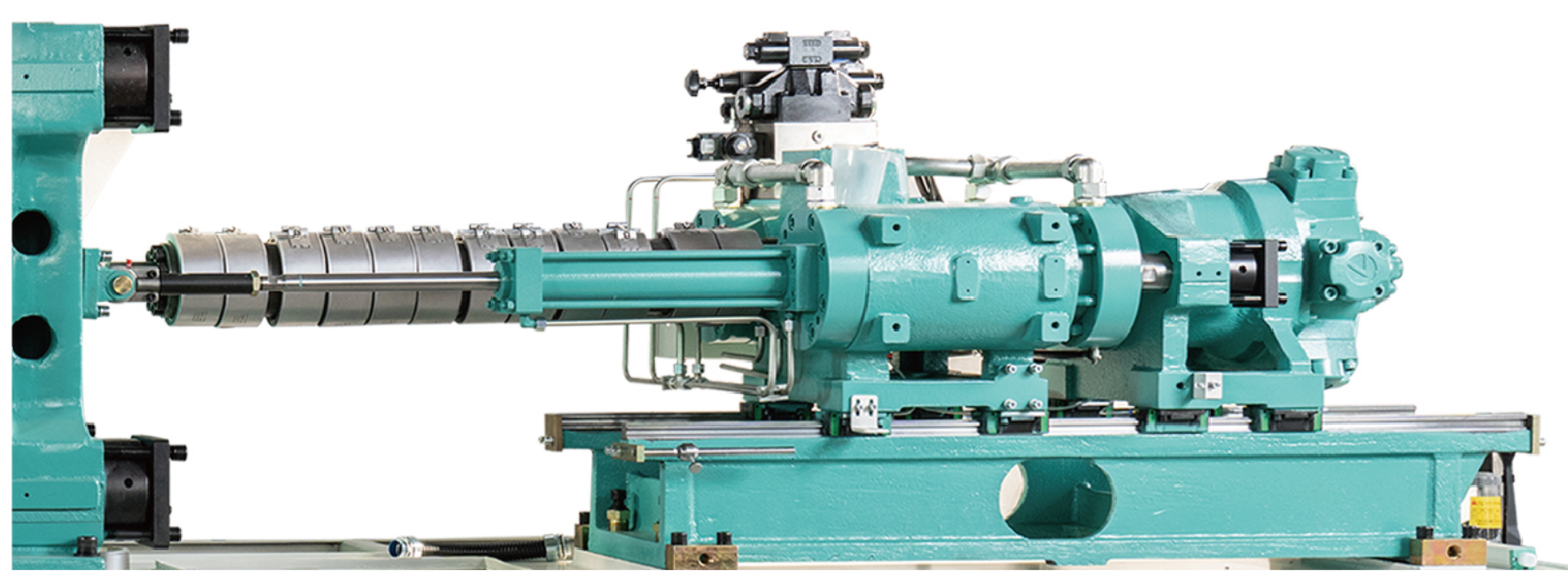

INJECTION UNIT

With over 20 years of experience in the research, development, and production of injection molding machines, we bring deep expertise to the table, ensuring our machines are at the forefront of innovation and performance.

Continuous Innovation: Decades of experience have driven the development of advanced molding technologies, including energy-efficient systems, high-speed machines, and precision molding capabilities. These innovations enhance the overall performance and versatility of injection molding machines, helping manufacturers keep pace with evolving market demands.

Customization Expertise: With extensive experience, we are well-equipped to design and build customized molding machines tailored to meet specific production needs, whether it’s for small batches, large-volume runs, or specialty products.

Reliable Support and Service: An established presence in the market ensures that we can provide ongoing technical support, maintenance, and training services, ensuring the longevity and efficiency of their equipment.

General-purpose injection molding machines are the workhorses of the plastics industry. They are designed to handle a wide range of materials and can produce various parts, making them highly versatile for different industries. These machines are commonly used for manufacturing plastic products in industries such as consumer goods, automotive, and electronics.

Material Flexibility: General-purpose machines can mold a wide variety of materials, including ABS, PVC, PP, PE, and PET. This makes them ideal for manufacturers who need to process multiple types of plastics.

Adjustable Parameters: These machines offer adjustable settings for injection pressure, temperature, and cycle time, providing flexibility to optimize for different material types and part specifications.

Standardized Design: They feature a simple, cost-effective design, making them suitable for mass production. The standardization of the process also helps to keep operational costs low.

High Reliability: General-purpose machines are built for long-lasting performance and are known for their reliability in producing quality products in high-volume manufacturing environments.

Consumer Products: From bottles to toys, general-purpose injection molding machines can handle the production of everyday plastic items.

Automotive Parts: Used to produce parts like dashboard components, plastic trims, and fasteners.

Packaging: They are heavily used in the packaging industry for manufacturing containers, caps, and closures.

General-purpose injection molding machines offer an excellent balance between cost, efficiency, and versatility, making them a popular choice for manufacturers across multiple industries.

Technical Parameter | |||||

Part | Name | Unit | NT280 | ||

Injection unit | SCREW DIAMETER | mm | 55 | 60 | 65 |

SCREW L/D RATIO | L/D | 22 | 20 | 18.3 | |

SHOT VOLUME(THEORETICAL) | CM3 | 677 | 805 | 945 | |

INJECTION WEIGHT(PS) | g | 616 | 732 | 860 | |

INJECTION PRESSURE | Mpa | 200 | 168 | 143 | |

INJECTION RATE | cm⊃3;/sec | 266 | 316 | 371 | |

PLASTICZATION CAPACITY(PS) | g/sec | 48 | 56 | 71 | |

INJECTION STROKE | mm | 285 | |||

INJECTION SPEED | Mm/sec | 112 | |||

SCREW SPEED | rpm | 210 | |||

Clamping unit | CLAMP FORCE | Kn | 2800 | ||

OPEN STROKE | mm | 590 | |||

SPACE BETWEEN TIE BARS | mm×mm | 630X580 | |||

MAX.MOULD HEIGHT | mm | 570 | |||

MIN.MOULD HEIGHT | mm | 190 | |||

EJECTOR STROKE | mm | 160 | |||

EJECTOR FORCE | Kn | 101 | |||

EJECTOR NUMBER | N | 13 | |||

Others | MAX.PUMP PRESSURE | Mpa | 16 | ||

PUMP MOTOR POWER | Kw | 39 | |||

HEATING POWER | Kw | 18.5 | |||

MACHINE DIMENSION(L*W*H) | m×m×m | 6.2*1.6*2.35 | |||

MACHINE WEIGHT(ESTIMATE) | T | 8.8 | |||

1. Q: What is the product range?

A: Focus on the manufacture and development of plastic injection molding machines and its auxiliary equipment such as cooling tower, chiller, etc.

2. Q: Where is your main selling market?

A: We have business domestic, USA, Russia, Indonesia, Egypt, Turkey, Uzbekistan, Pakistan, etc.

3. Q: Will you offer field installation and operator training at the buyer's factory?

A: Yes, we will arrange our skilled engineers for filed installation and training.

4. Q: What is the delivery time(equipment production time)?

A: It will be ready around 50-75 days after getting mutual confirmation about the order details and prepayment.

5. Q: Do you also have source for molds and spare parts?

A: Yes, we can offer with the competitive quality and reasonable price. Customized as required.

6. Q: What is the standard of package?

A: Wooden case packing for the auxiliary equipment, bare packing for the plastic injection molding machine. Full container shipment is highly suggest.

CLAMPING UNIT

INJECTION UNIT

With over 20 years of experience in the research, development, and production of injection molding machines, we bring deep expertise to the table, ensuring our machines are at the forefront of innovation and performance.

Continuous Innovation: Decades of experience have driven the development of advanced molding technologies, including energy-efficient systems, high-speed machines, and precision molding capabilities. These innovations enhance the overall performance and versatility of injection molding machines, helping manufacturers keep pace with evolving market demands.

Customization Expertise: With extensive experience, we are well-equipped to design and build customized molding machines tailored to meet specific production needs, whether it’s for small batches, large-volume runs, or specialty products.

Reliable Support and Service: An established presence in the market ensures that we can provide ongoing technical support, maintenance, and training services, ensuring the longevity and efficiency of their equipment.

General-purpose injection molding machines are the workhorses of the plastics industry. They are designed to handle a wide range of materials and can produce various parts, making them highly versatile for different industries. These machines are commonly used for manufacturing plastic products in industries such as consumer goods, automotive, and electronics.

Material Flexibility: General-purpose machines can mold a wide variety of materials, including ABS, PVC, PP, PE, and PET. This makes them ideal for manufacturers who need to process multiple types of plastics.

Adjustable Parameters: These machines offer adjustable settings for injection pressure, temperature, and cycle time, providing flexibility to optimize for different material types and part specifications.

Standardized Design: They feature a simple, cost-effective design, making them suitable for mass production. The standardization of the process also helps to keep operational costs low.

High Reliability: General-purpose machines are built for long-lasting performance and are known for their reliability in producing quality products in high-volume manufacturing environments.

Consumer Products: From bottles to toys, general-purpose injection molding machines can handle the production of everyday plastic items.

Automotive Parts: Used to produce parts like dashboard components, plastic trims, and fasteners.

Packaging: They are heavily used in the packaging industry for manufacturing containers, caps, and closures.

General-purpose injection molding machines offer an excellent balance between cost, efficiency, and versatility, making them a popular choice for manufacturers across multiple industries.

Technical Parameter | |||||

Part | Name | Unit | NT280 | ||

Injection unit | SCREW DIAMETER | mm | 55 | 60 | 65 |

SCREW L/D RATIO | L/D | 22 | 20 | 18.3 | |

SHOT VOLUME(THEORETICAL) | CM3 | 677 | 805 | 945 | |

INJECTION WEIGHT(PS) | g | 616 | 732 | 860 | |

INJECTION PRESSURE | Mpa | 200 | 168 | 143 | |

INJECTION RATE | cm⊃3;/sec | 266 | 316 | 371 | |

PLASTICZATION CAPACITY(PS) | g/sec | 48 | 56 | 71 | |

INJECTION STROKE | mm | 285 | |||

INJECTION SPEED | Mm/sec | 112 | |||

SCREW SPEED | rpm | 210 | |||

Clamping unit | CLAMP FORCE | Kn | 2800 | ||

OPEN STROKE | mm | 590 | |||

SPACE BETWEEN TIE BARS | mm×mm | 630X580 | |||

MAX.MOULD HEIGHT | mm | 570 | |||

MIN.MOULD HEIGHT | mm | 190 | |||

EJECTOR STROKE | mm | 160 | |||

EJECTOR FORCE | Kn | 101 | |||

EJECTOR NUMBER | N | 13 | |||

Others | MAX.PUMP PRESSURE | Mpa | 16 | ||

PUMP MOTOR POWER | Kw | 39 | |||

HEATING POWER | Kw | 18.5 | |||

MACHINE DIMENSION(L*W*H) | m×m×m | 6.2*1.6*2.35 | |||

MACHINE WEIGHT(ESTIMATE) | T | 8.8 | |||

1. Q: What is the product range?

A: Focus on the manufacture and development of plastic injection molding machines and its auxiliary equipment such as cooling tower, chiller, etc.

2. Q: Where is your main selling market?

A: We have business domestic, USA, Russia, Indonesia, Egypt, Turkey, Uzbekistan, Pakistan, etc.

3. Q: Will you offer field installation and operator training at the buyer's factory?

A: Yes, we will arrange our skilled engineers for filed installation and training.

4. Q: What is the delivery time(equipment production time)?

A: It will be ready around 50-75 days after getting mutual confirmation about the order details and prepayment.

5. Q: Do you also have source for molds and spare parts?

A: Yes, we can offer with the competitive quality and reasonable price. Customized as required.

6. Q: What is the standard of package?

A: Wooden case packing for the auxiliary equipment, bare packing for the plastic injection molding machine. Full container shipment is highly suggest.