Please Choose Your Language

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

NT320

LEANTALL

8477101090

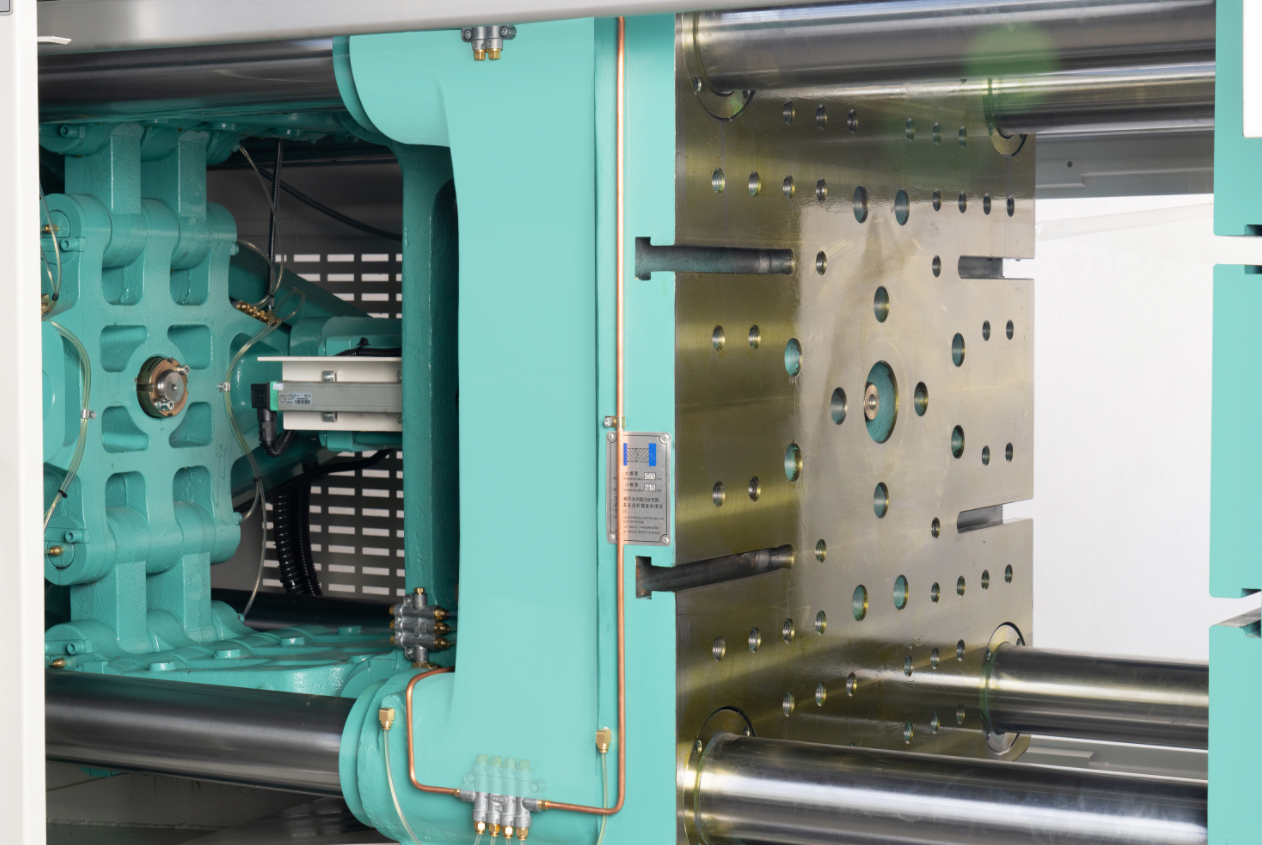

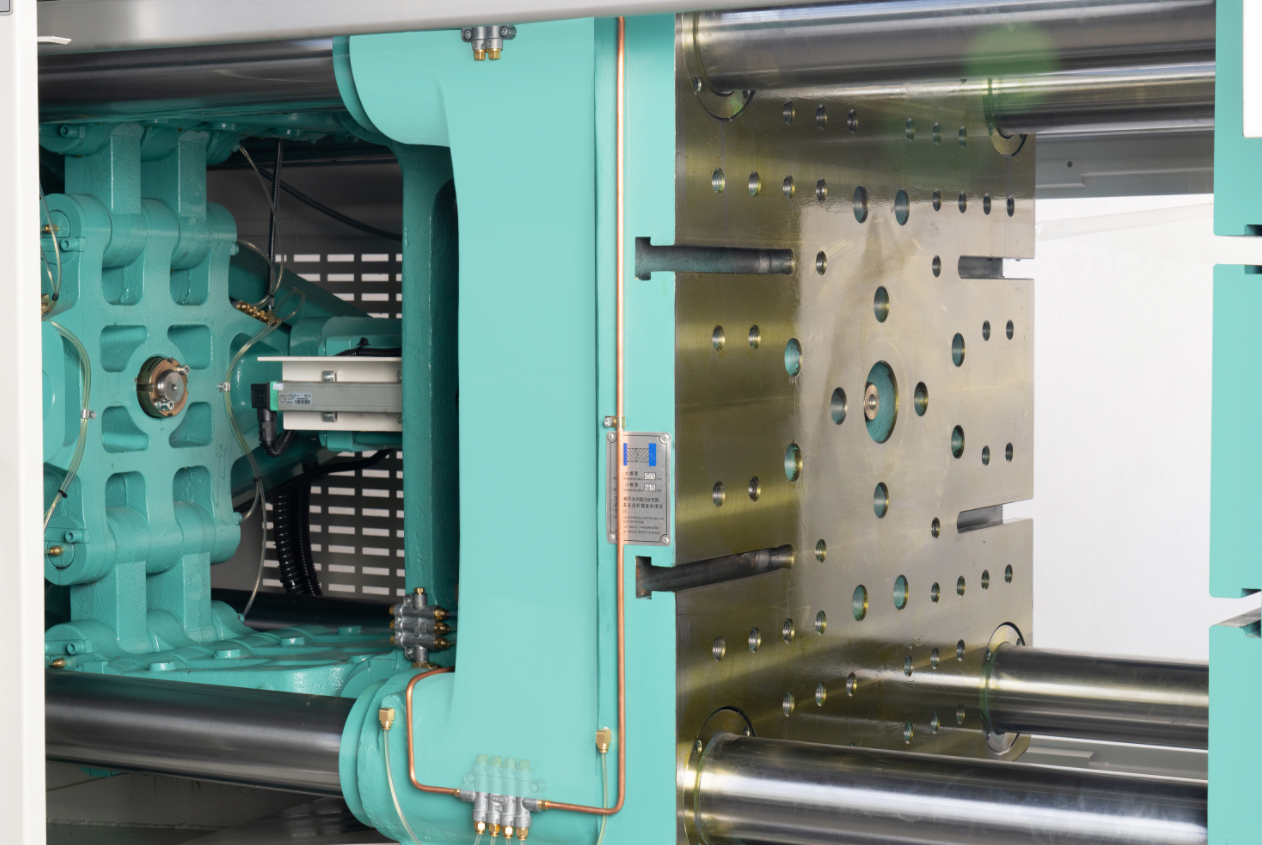

CLAMPING UNIT

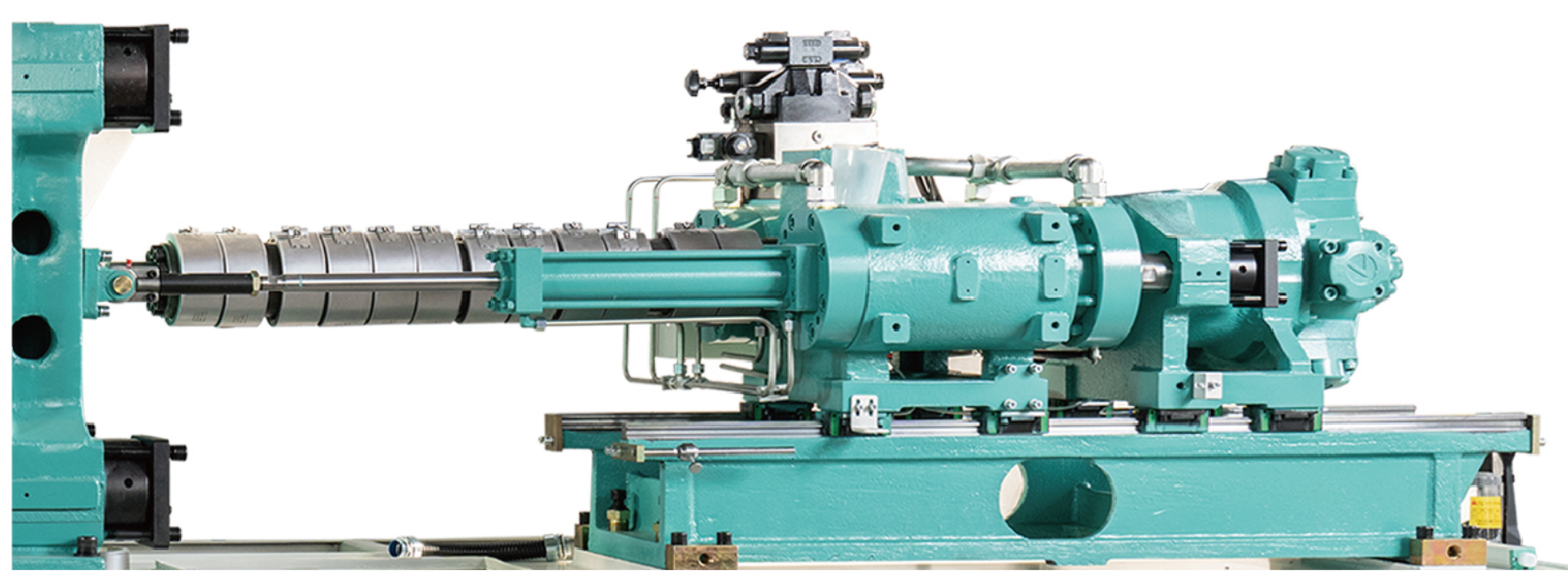

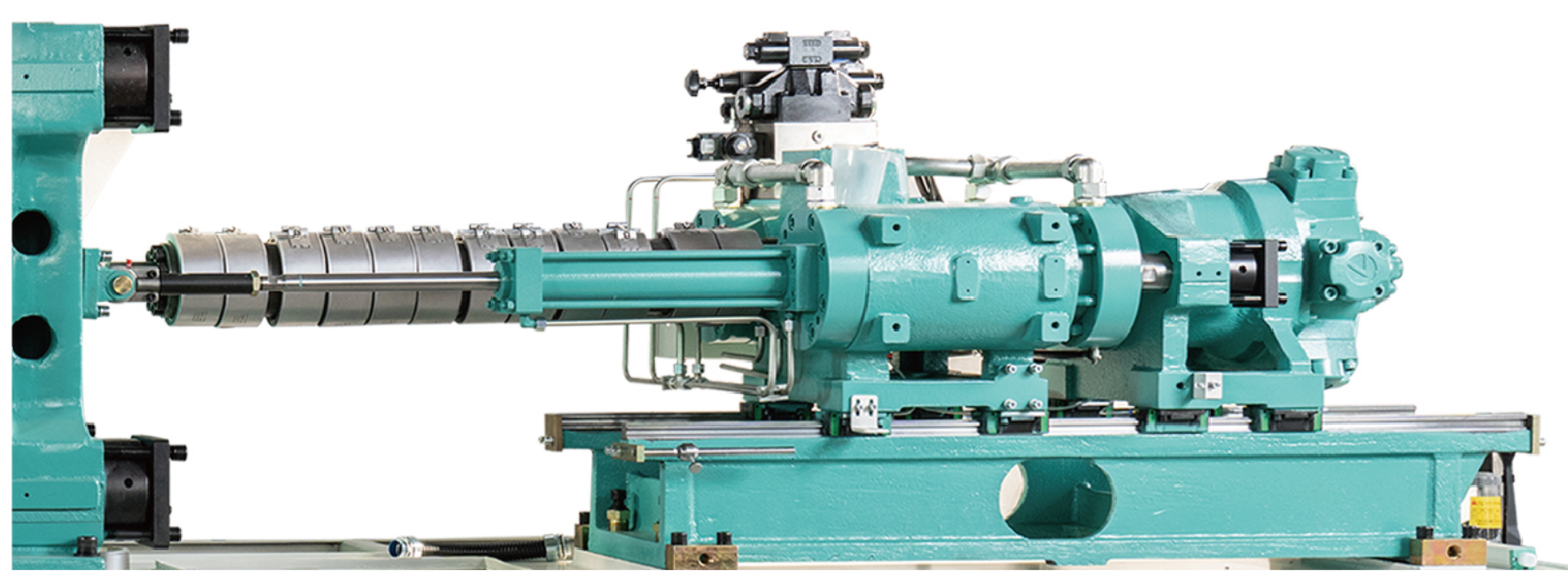

INJECTION UNIT

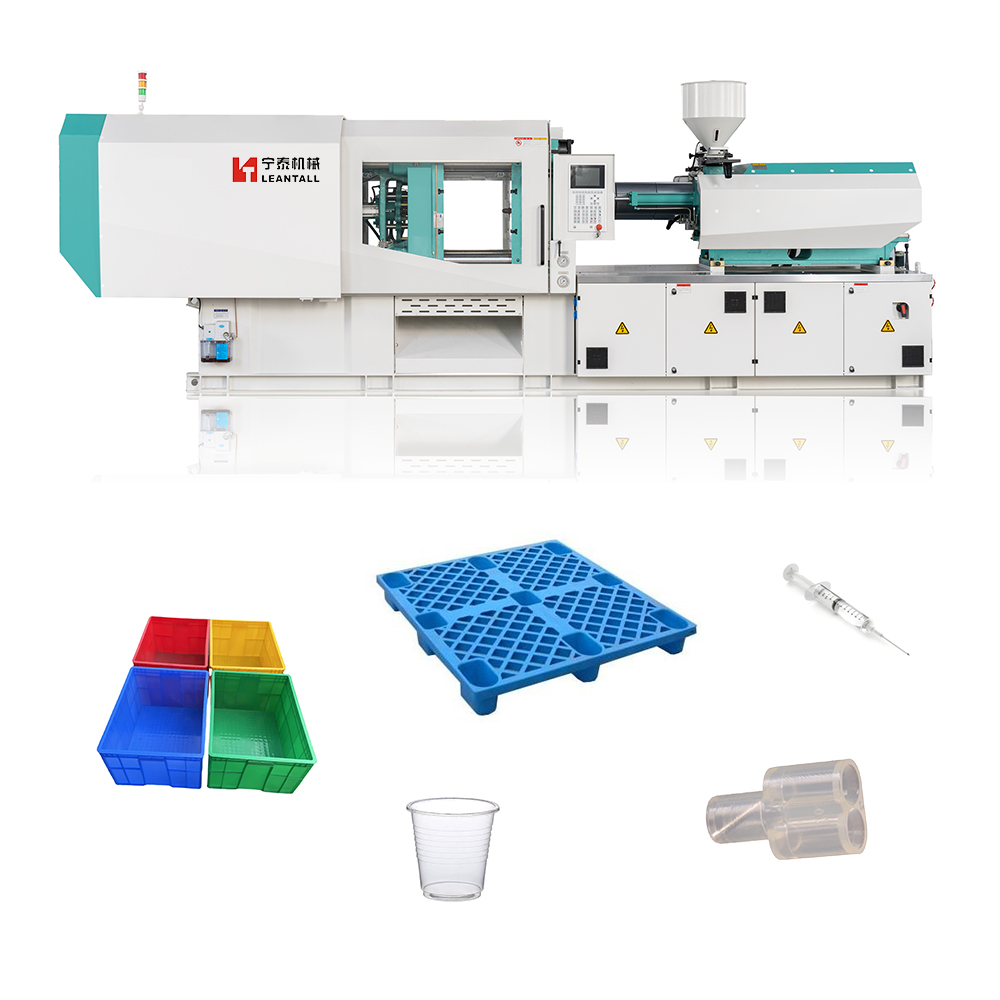

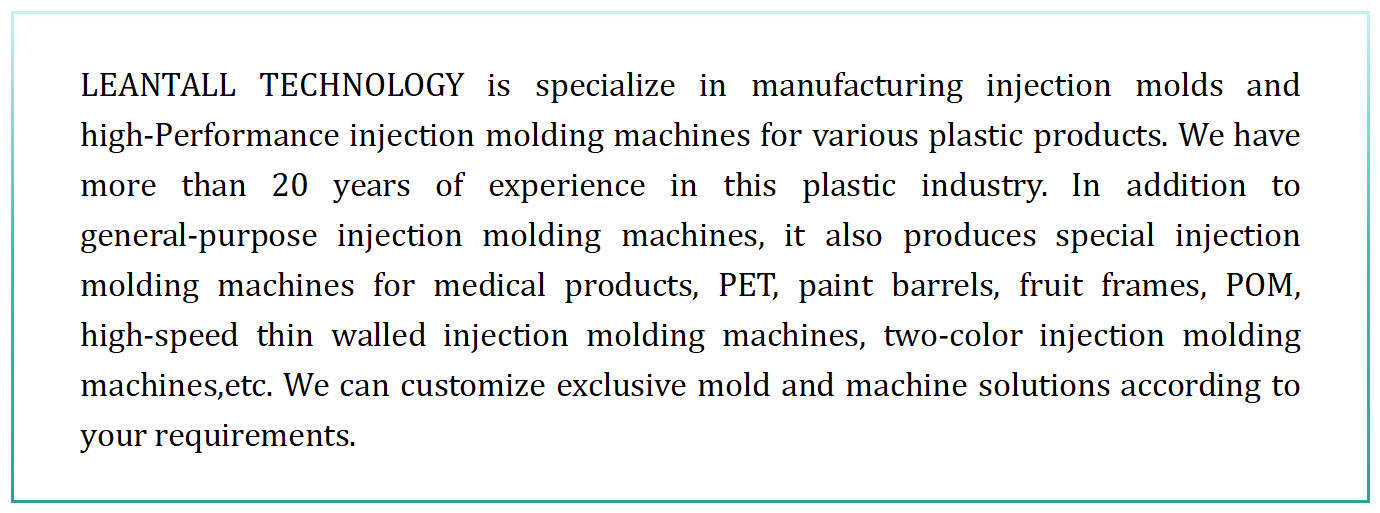

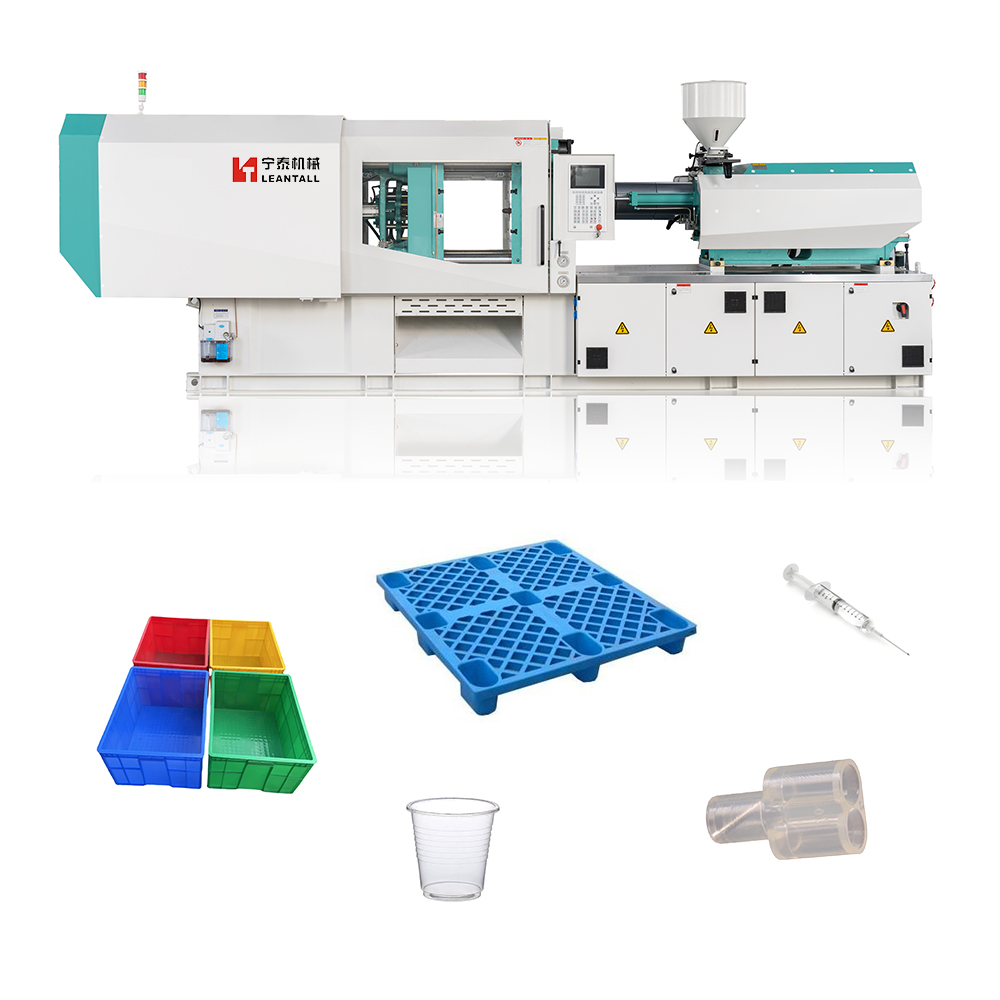

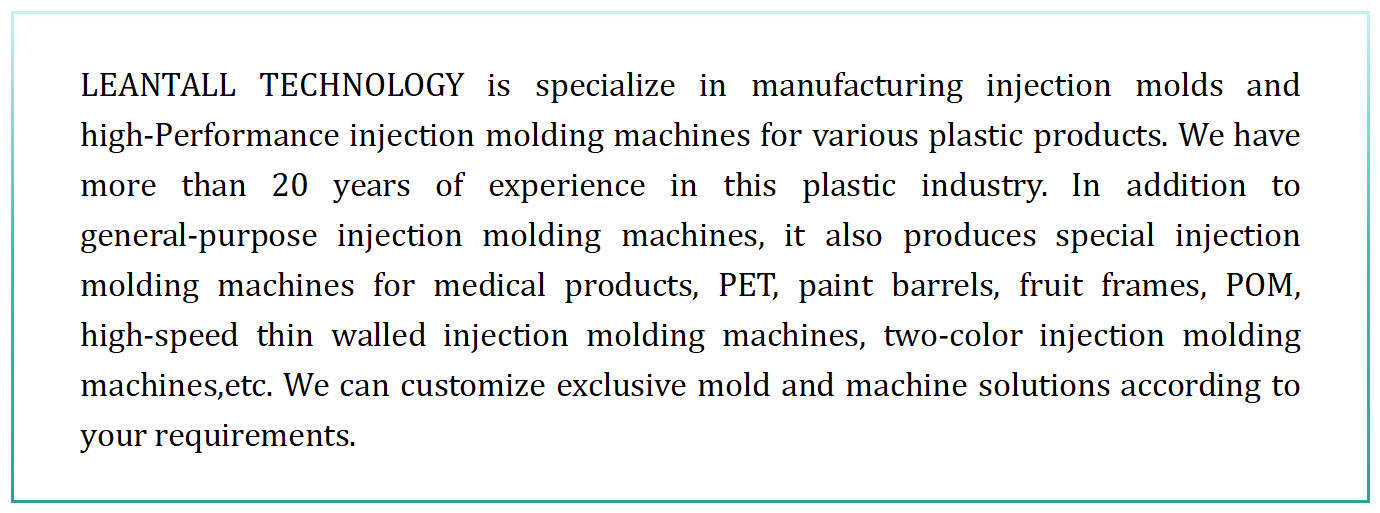

Injection molding machines for paint barrels are specially designed to manufacture large, durable plastic containers used for storing paint and other industrial liquids. These machines are built to handle large volumes of material and are optimized for producing thick-walled, heavy-duty barrels that can withstand the pressures of industrial storage and transport.

Large Mold Capacity: Paint barrel molding machines can accommodate larger molds to create the large, thick-walled plastic containers required by industries such as paint, chemicals, and construction.

High Injection Pressure: These machines are designed to operate at higher injection pressures, which helps in forming thicker parts that maintain their strength and durability.

Enhanced Cooling Systems: Given the thickness of the parts being molded, these machines are equipped with advanced cooling systems to reduce cycle times and improve the efficiency of the production process.

Material Compatibility: They are designed to process high-density polyethylene (HDPE) or other strong polymers, which are ideal for creating tough, impact-resistant containers.

Paint Storage and Transport: Molding paint barrels, drums, and containers used for storing and shipping large quantities of liquid products.

Chemical Containers: Producing containers that hold industrial chemicals, solvents, and lubricants.

Bulk Material Storage: These machines are also used in manufacturing large plastic containers for storing and transporting bulk materials in other industries.

Injection molding machines for paint barrels are vital for ensuring the strength, durability, and cost-effectiveness of large-scale production of industrial containers.

Technical Parameter | |||||

Part | Name | Unit | NT320 | ||

Injection unit | SCREW DIAMETER | mm | 60 | 65 | 70 |

SCREW L/D RATIO | L/D | 21.6 | 20 | 18.5 | |

SHOT VOLUME(THEORETICAL) | CM3 | 848 | 995 | 1154 | |

INJECTION WEIGHT(PS) | g | 771 | 905 | 1050 | |

INJECTION PRESSURE | Mpa | 176 | 150 | 129 | |

INJECTION RATE | cm⊃3;/sec | 302 | 355 | 412 | |

PLASTICZATION CAPACITY(PS) | g/sec | 48 | 63 | 76 | |

INJECTION STROKE | mm | 300 | |||

INJECTION SPEED | Mm/sec | 107 | |||

SCREW SPEED | rpm | 180 | |||

Clamping unit | CLAMP FORCE | Kn | 3200 | ||

OPEN STROKE | mm | 620 | |||

SPACE BETWEEN TIE BARS | mm×mm | 660X625 | |||

MAX.MOULD HEIGHT | mm | 630 | |||

MIN.MOULD HEIGHT | mm | 230 | |||

EJECTOR STROKE | mm | 160 | |||

EJECTOR FORCE | Kn | 101 | |||

EJECTOR NUMBER | N | 13 | |||

Others | MAX.PUMP PRESSURE | Mpa | 16 | ||

PUMP MOTOR POWER | Kw | 39 | |||

HEATING POWER | Kw | 18.5 | |||

MACHINE DIMENSION(L*W*H) | m×m×m | 6.45*1.65*2.35 | |||

MACHINE WEIGHT(ESTIMATE) | T | 9.0 | |||

1. Q: What is the product range?

A: Focus on the manufacture and development of plastic injection molding machines and its auxiliary equipment such as cooling tower, chiller, etc.

2. Q: Where is your main selling market?

A: We have business domestic, USA, Russia, Indonesia, Egypt, Turkey, Uzbekistan, Pakistan, etc.

3. Q: Will you offer field installation and operator training at the buyer's factory?

A: Yes, we will arrange our skilled engineers for filed installation and training.

4. Q: What is the delivery time(equipment production time)?

A: It will be ready around 50-75 days after getting mutual confirmation about the order details and prepayment.

5. Q: Do you also have source for molds and spare parts?

A: Yes, we can offer with the competitive quality and reasonable price. Customized as required.

6. Q: What is the standard of package?

A: Wooden case packing for the auxiliary equipment, bare packing for the plastic injection molding machine. Full container shipment is highly suggest.

CLAMPING UNIT

INJECTION UNIT

Injection molding machines for paint barrels are specially designed to manufacture large, durable plastic containers used for storing paint and other industrial liquids. These machines are built to handle large volumes of material and are optimized for producing thick-walled, heavy-duty barrels that can withstand the pressures of industrial storage and transport.

Large Mold Capacity: Paint barrel molding machines can accommodate larger molds to create the large, thick-walled plastic containers required by industries such as paint, chemicals, and construction.

High Injection Pressure: These machines are designed to operate at higher injection pressures, which helps in forming thicker parts that maintain their strength and durability.

Enhanced Cooling Systems: Given the thickness of the parts being molded, these machines are equipped with advanced cooling systems to reduce cycle times and improve the efficiency of the production process.

Material Compatibility: They are designed to process high-density polyethylene (HDPE) or other strong polymers, which are ideal for creating tough, impact-resistant containers.

Paint Storage and Transport: Molding paint barrels, drums, and containers used for storing and shipping large quantities of liquid products.

Chemical Containers: Producing containers that hold industrial chemicals, solvents, and lubricants.

Bulk Material Storage: These machines are also used in manufacturing large plastic containers for storing and transporting bulk materials in other industries.

Injection molding machines for paint barrels are vital for ensuring the strength, durability, and cost-effectiveness of large-scale production of industrial containers.

Technical Parameter | |||||

Part | Name | Unit | NT320 | ||

Injection unit | SCREW DIAMETER | mm | 60 | 65 | 70 |

SCREW L/D RATIO | L/D | 21.6 | 20 | 18.5 | |

SHOT VOLUME(THEORETICAL) | CM3 | 848 | 995 | 1154 | |

INJECTION WEIGHT(PS) | g | 771 | 905 | 1050 | |

INJECTION PRESSURE | Mpa | 176 | 150 | 129 | |

INJECTION RATE | cm⊃3;/sec | 302 | 355 | 412 | |

PLASTICZATION CAPACITY(PS) | g/sec | 48 | 63 | 76 | |

INJECTION STROKE | mm | 300 | |||

INJECTION SPEED | Mm/sec | 107 | |||

SCREW SPEED | rpm | 180 | |||

Clamping unit | CLAMP FORCE | Kn | 3200 | ||

OPEN STROKE | mm | 620 | |||

SPACE BETWEEN TIE BARS | mm×mm | 660X625 | |||

MAX.MOULD HEIGHT | mm | 630 | |||

MIN.MOULD HEIGHT | mm | 230 | |||

EJECTOR STROKE | mm | 160 | |||

EJECTOR FORCE | Kn | 101 | |||

EJECTOR NUMBER | N | 13 | |||

Others | MAX.PUMP PRESSURE | Mpa | 16 | ||

PUMP MOTOR POWER | Kw | 39 | |||

HEATING POWER | Kw | 18.5 | |||

MACHINE DIMENSION(L*W*H) | m×m×m | 6.45*1.65*2.35 | |||

MACHINE WEIGHT(ESTIMATE) | T | 9.0 | |||

1. Q: What is the product range?

A: Focus on the manufacture and development of plastic injection molding machines and its auxiliary equipment such as cooling tower, chiller, etc.

2. Q: Where is your main selling market?

A: We have business domestic, USA, Russia, Indonesia, Egypt, Turkey, Uzbekistan, Pakistan, etc.

3. Q: Will you offer field installation and operator training at the buyer's factory?

A: Yes, we will arrange our skilled engineers for filed installation and training.

4. Q: What is the delivery time(equipment production time)?

A: It will be ready around 50-75 days after getting mutual confirmation about the order details and prepayment.

5. Q: Do you also have source for molds and spare parts?

A: Yes, we can offer with the competitive quality and reasonable price. Customized as required.

6. Q: What is the standard of package?

A: Wooden case packing for the auxiliary equipment, bare packing for the plastic injection molding machine. Full container shipment is highly suggest.