Please Choose Your Language

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

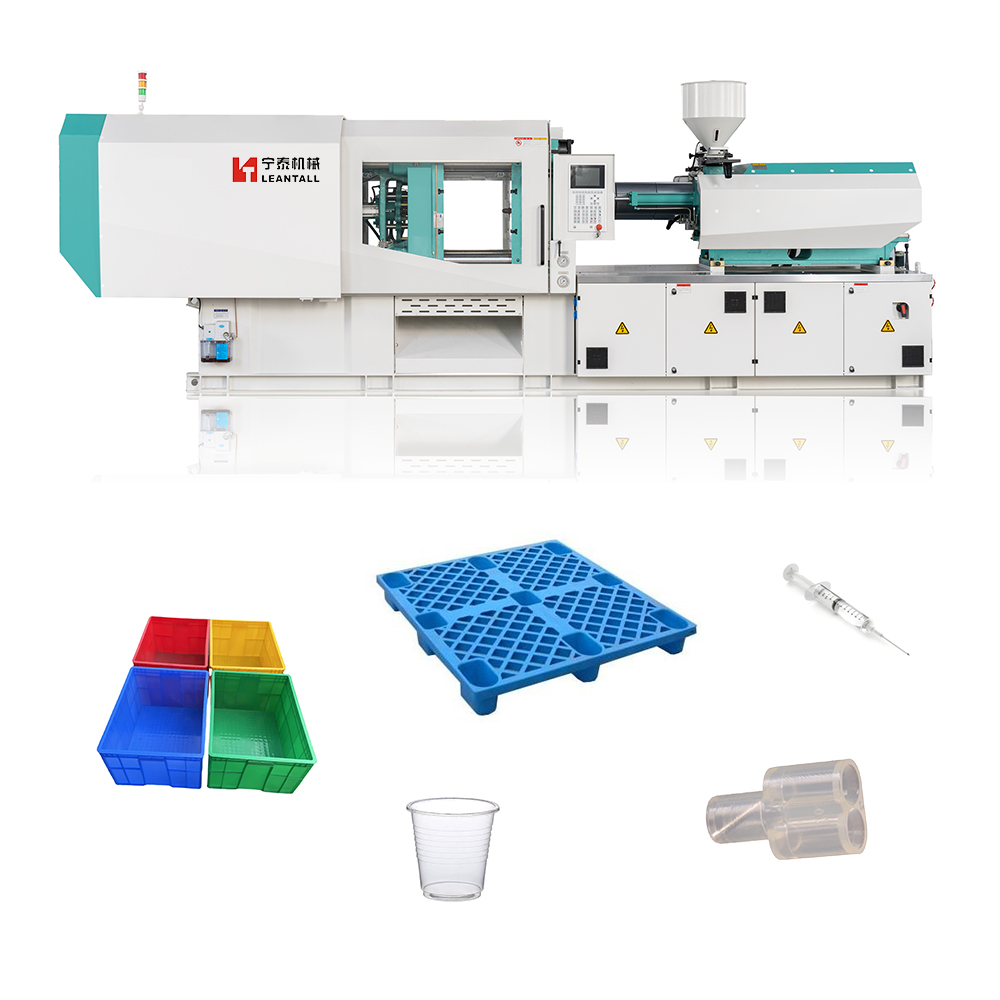

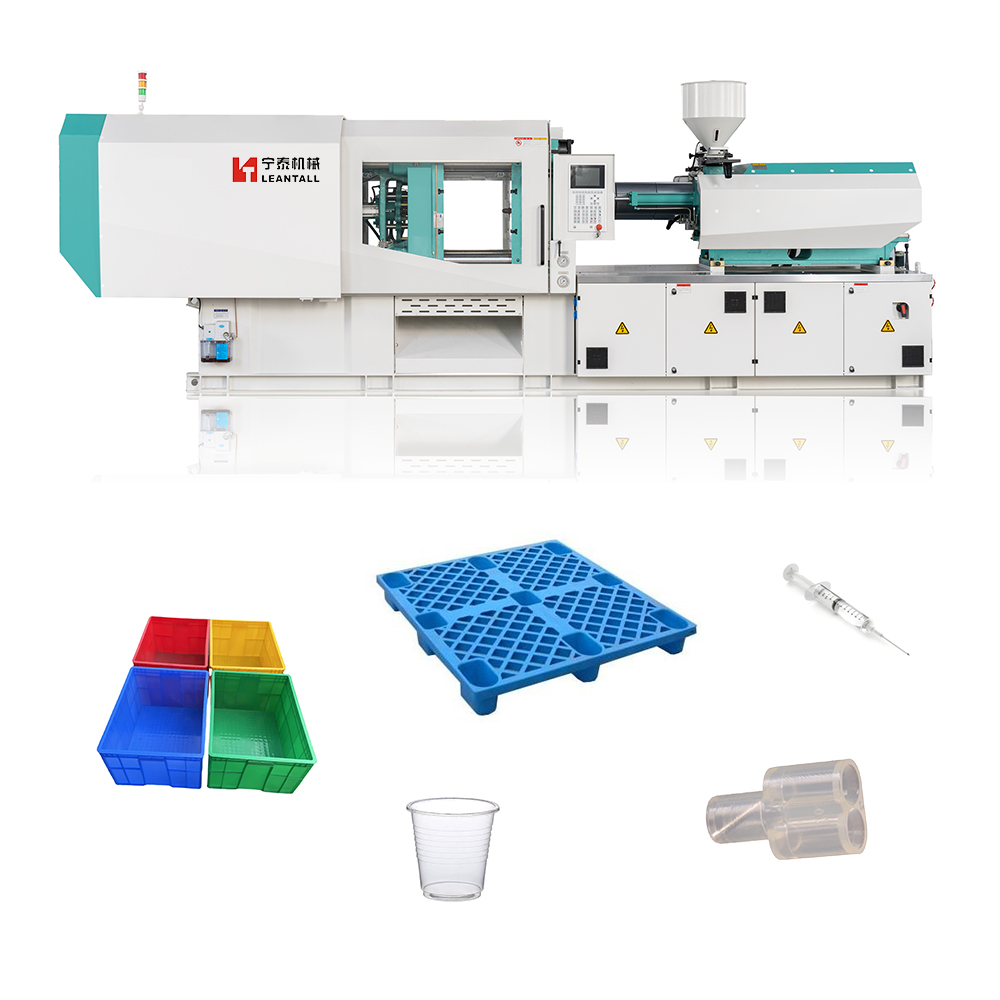

NT300

LEANTALL

8477101090

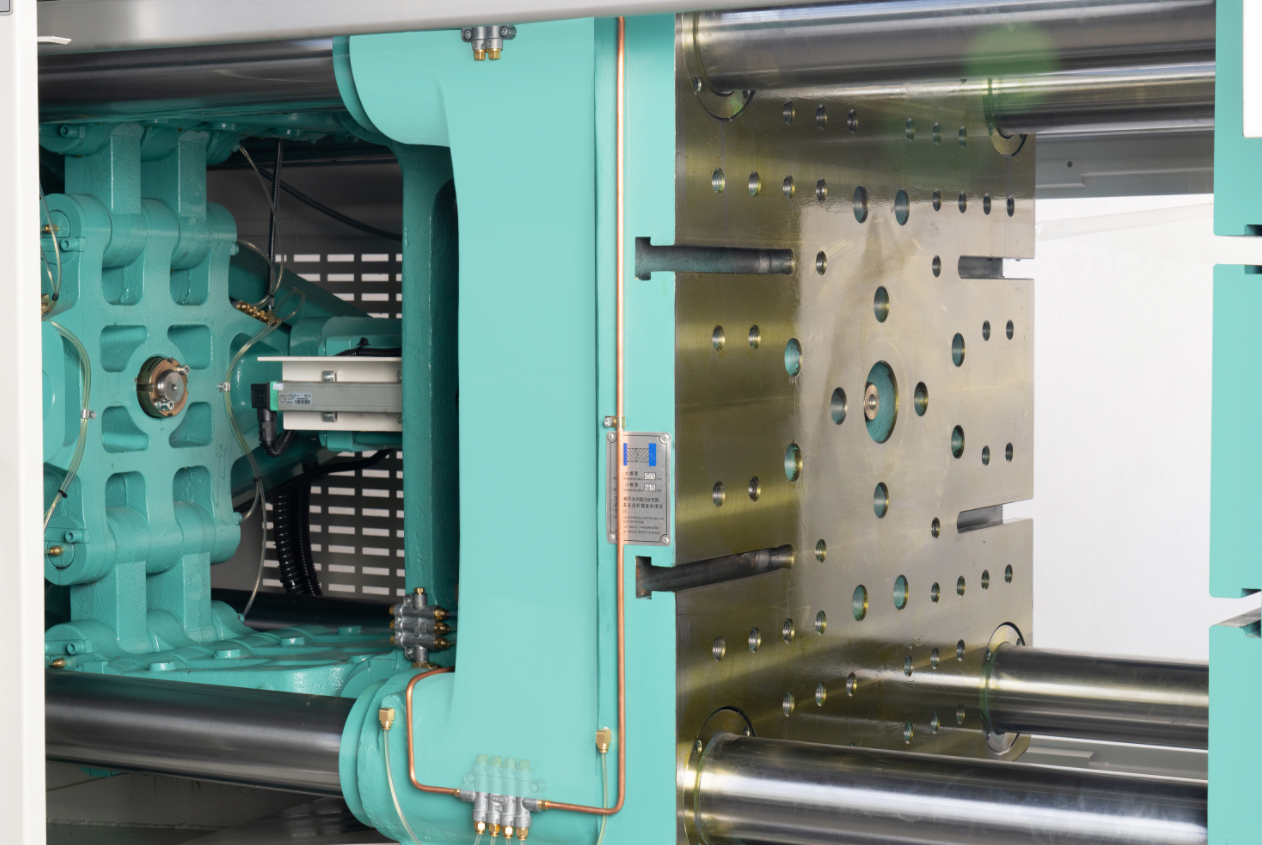

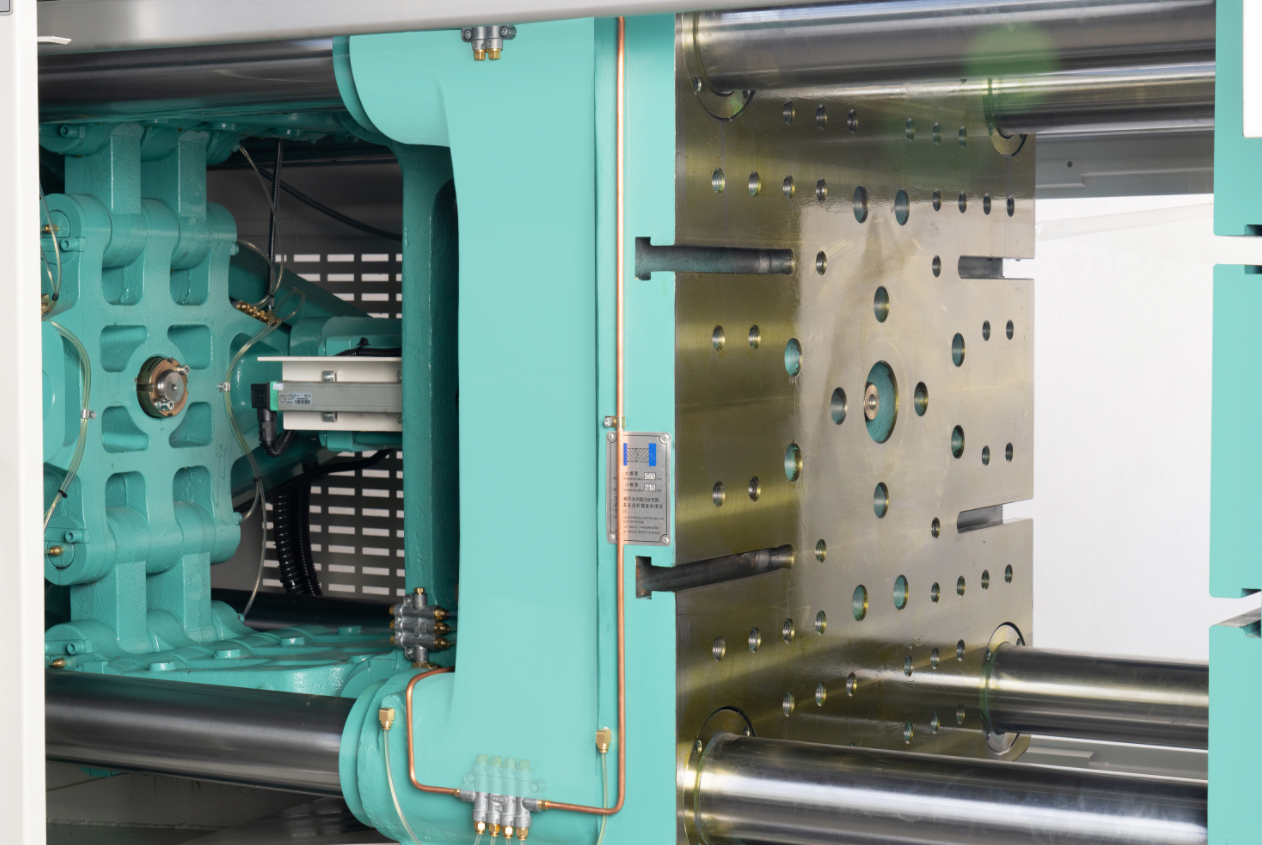

CLAMPING UNIT

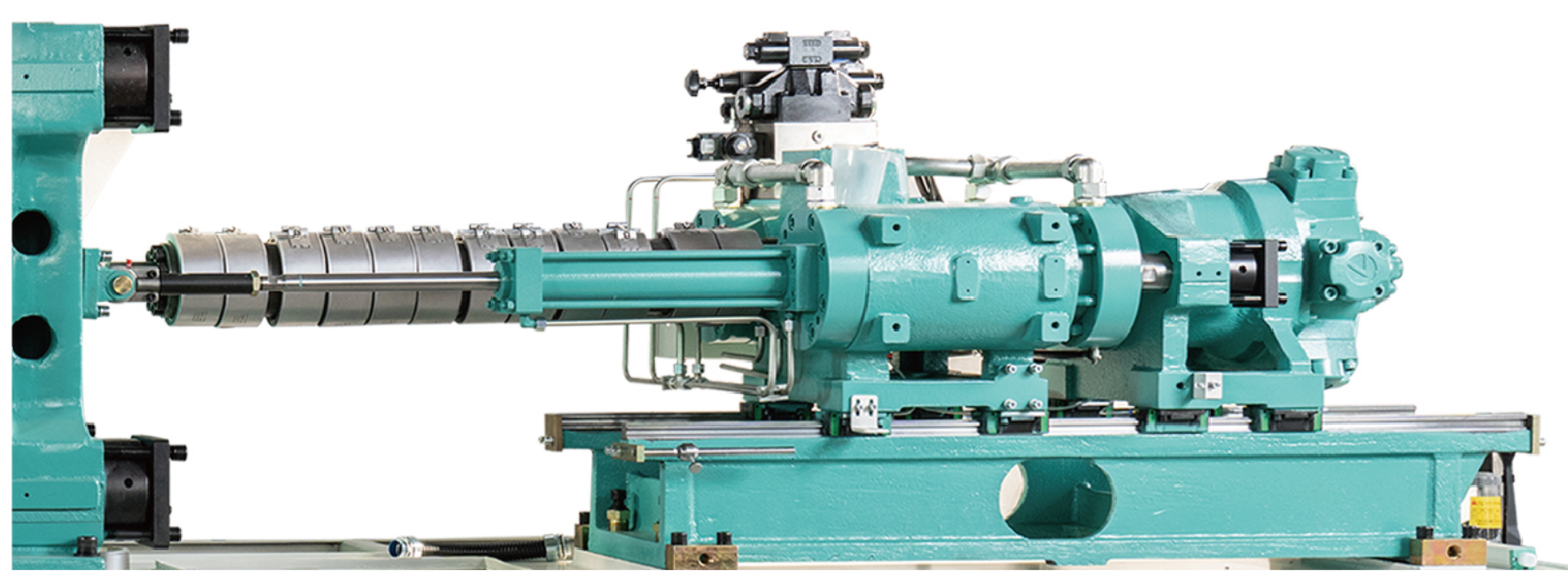

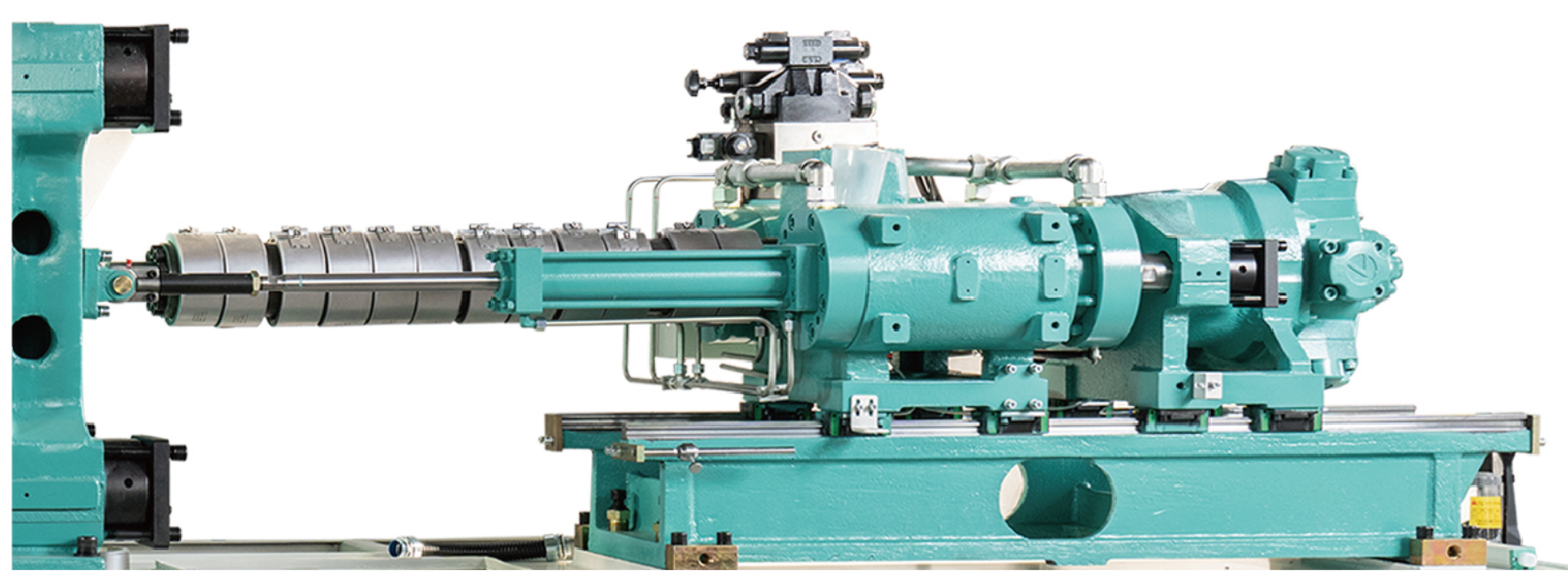

INJECTION UNIT

2. Injection: Forcing Melt into the Mold

The second stage—injection—is where the molten plastic is pushed into the mold cavity. The mold itself is a two-part metal tool (usually made of steel or aluminum) custom-designed to match the shape of the desired product. Before injection begins, the mold’s two halves (the “fixed half” and “moving half”) are already closed and secured by the machine’s clamping unit (a detail expanded on in the next stage).

To inject the melt, the screw acts as a piston: hydraulic or electric actuators push the screw forward rapidly, applying high pressure to the molten plastic. This pressure (known as “injection pressure”) ranges from 10 to 200 MPa (1,450 to 29,000 psi), depending on the plastic’s viscosity and the mold’s complexity. The high pressure ensures the melt fills every detail of the mold cavity—even tiny features like ribs, holes, or text. The melt flows through a narrow opening at the end of the barrel called the “nozzle,” which connects directly to the mold’s “sprue” (a channel that distributes the melt to the cavity). The injection stage is completed once the mold cavity is fully filled with melt.

Technical Parameter | |||||

Part | Name | Unit | NT300 | ||

Injection unit | SCREW DIAMETER | mm | 55 | 60 | 65 |

SCREW L/D RATIO | L/D | 23 | 21 | 19 | |

SHOT VOLUME(THEORETICAL) | CM3 | 677 | 805 | 945 | |

INJECTION WEIGHT(PS) | g | 616 | 732 | 860 | |

INJECTION PRESSURE | Mpa | 202 | 170 | 145 | |

INJECTION RATE | cm⊃3;/sec | 261 | 311 | 365 | |

PLASTICZATION CAPACITY(PS) | g/sec | 48 | 56 | 71 | |

INJECTION STROKE | mm | 285 | |||

INJECTION SPEED | Mm/sec | 110 | |||

SCREW SPEED | rpm | 210 | |||

Clamping unit | CLAMP FORCE | Kn | 3000 | ||

OPEN STROKE | mm | 590 | |||

SPACE BETWEEN TIE BARS | mm×mm | 630X630 | |||

MAX.MOULD HEIGHT | mm | 630 | |||

MIN.MOULD HEIGHT | mm | 200 | |||

EJECTOR STROKE | mm | 135 | |||

EJECTOR FORCE | Kn | 90 | |||

EJECTOR NUMBER | N | 9 | |||

Others | MAX.PUMP PRESSURE | Mpa | 16 | ||

PUMP MOTOR POWER | Kw | 39 | |||

HEATING POWER | Kw | 18.5 | |||

MACHINE DIMENSION(L*W*H) | m×m×m | 6.35*1.6*2.35 | |||

MACHINE WEIGHT(ESTIMATE) | T | 9.0 | |||

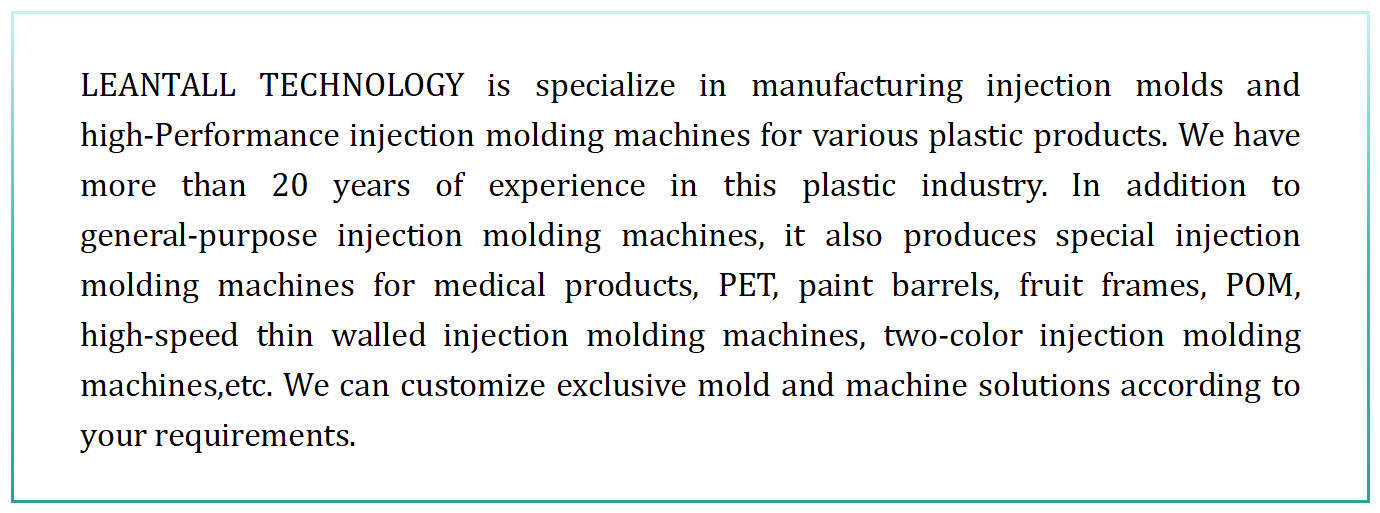

1. Q: What is the product range?

A: Focus on the manufacture and development of plastic injection molding machines and its auxiliary equipment such as cooling tower, chiller, etc.

2. Q: Where is your main selling market?

A: We have business domestic, USA, Russia, Indonesia, Egypt, Turkey, Uzbekistan, Pakistan, etc.

3. Q: Will you offer field installation and operator training at the buyer's factory?

A: Yes, we will arrange our skilled engineers for filed installation and training.

4. Q: What is the delivery time(equipment production time)?

A: It will be ready around 50-75 days after getting mutual confirmation about the order details and prepayment.

5. Q: Do you also have source for molds and spare parts?

A: Yes, we can offer with the competitive quality and reasonable price. Customized as required.

6. Q: What is the standard of package?

A: Wooden case packing for the auxiliary equipment, bare packing for the plastic injection molding machine. Full container shipment is highly suggest.

CLAMPING UNIT

INJECTION UNIT

2. Injection: Forcing Melt into the Mold

The second stage—injection—is where the molten plastic is pushed into the mold cavity. The mold itself is a two-part metal tool (usually made of steel or aluminum) custom-designed to match the shape of the desired product. Before injection begins, the mold’s two halves (the “fixed half” and “moving half”) are already closed and secured by the machine’s clamping unit (a detail expanded on in the next stage).

To inject the melt, the screw acts as a piston: hydraulic or electric actuators push the screw forward rapidly, applying high pressure to the molten plastic. This pressure (known as “injection pressure”) ranges from 10 to 200 MPa (1,450 to 29,000 psi), depending on the plastic’s viscosity and the mold’s complexity. The high pressure ensures the melt fills every detail of the mold cavity—even tiny features like ribs, holes, or text. The melt flows through a narrow opening at the end of the barrel called the “nozzle,” which connects directly to the mold’s “sprue” (a channel that distributes the melt to the cavity). The injection stage is completed once the mold cavity is fully filled with melt.

Technical Parameter | |||||

Part | Name | Unit | NT300 | ||

Injection unit | SCREW DIAMETER | mm | 55 | 60 | 65 |

SCREW L/D RATIO | L/D | 23 | 21 | 19 | |

SHOT VOLUME(THEORETICAL) | CM3 | 677 | 805 | 945 | |

INJECTION WEIGHT(PS) | g | 616 | 732 | 860 | |

INJECTION PRESSURE | Mpa | 202 | 170 | 145 | |

INJECTION RATE | cm⊃3;/sec | 261 | 311 | 365 | |

PLASTICZATION CAPACITY(PS) | g/sec | 48 | 56 | 71 | |

INJECTION STROKE | mm | 285 | |||

INJECTION SPEED | Mm/sec | 110 | |||

SCREW SPEED | rpm | 210 | |||

Clamping unit | CLAMP FORCE | Kn | 3000 | ||

OPEN STROKE | mm | 590 | |||

SPACE BETWEEN TIE BARS | mm×mm | 630X630 | |||

MAX.MOULD HEIGHT | mm | 630 | |||

MIN.MOULD HEIGHT | mm | 200 | |||

EJECTOR STROKE | mm | 135 | |||

EJECTOR FORCE | Kn | 90 | |||

EJECTOR NUMBER | N | 9 | |||

Others | MAX.PUMP PRESSURE | Mpa | 16 | ||

PUMP MOTOR POWER | Kw | 39 | |||

HEATING POWER | Kw | 18.5 | |||

MACHINE DIMENSION(L*W*H) | m×m×m | 6.35*1.6*2.35 | |||

MACHINE WEIGHT(ESTIMATE) | T | 9.0 | |||

1. Q: What is the product range?

A: Focus on the manufacture and development of plastic injection molding machines and its auxiliary equipment such as cooling tower, chiller, etc.

2. Q: Where is your main selling market?

A: We have business domestic, USA, Russia, Indonesia, Egypt, Turkey, Uzbekistan, Pakistan, etc.

3. Q: Will you offer field installation and operator training at the buyer's factory?

A: Yes, we will arrange our skilled engineers for filed installation and training.

4. Q: What is the delivery time(equipment production time)?

A: It will be ready around 50-75 days after getting mutual confirmation about the order details and prepayment.

5. Q: Do you also have source for molds and spare parts?

A: Yes, we can offer with the competitive quality and reasonable price. Customized as required.

6. Q: What is the standard of package?

A: Wooden case packing for the auxiliary equipment, bare packing for the plastic injection molding machine. Full container shipment is highly suggest.