Please Choose Your Language

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

NT320

LEANTALL

8477101090

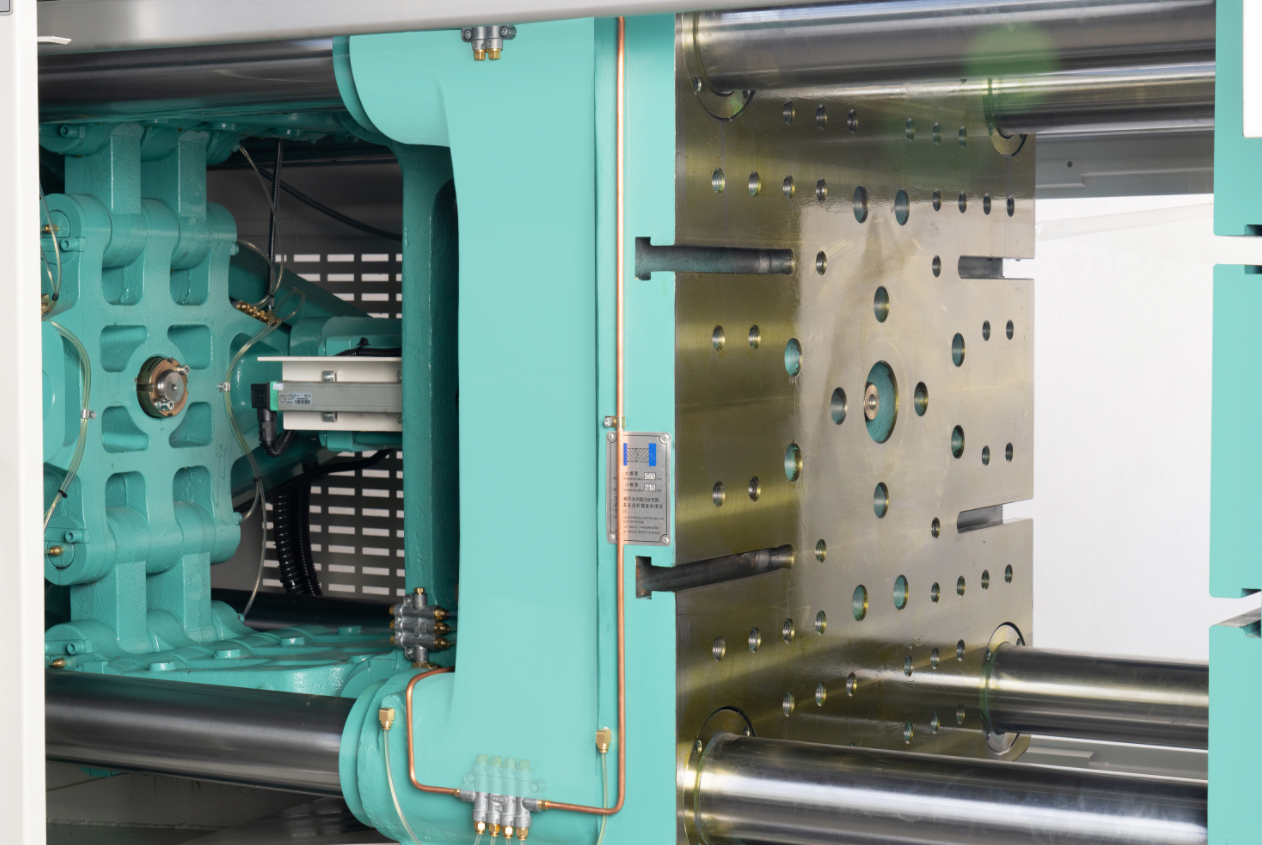

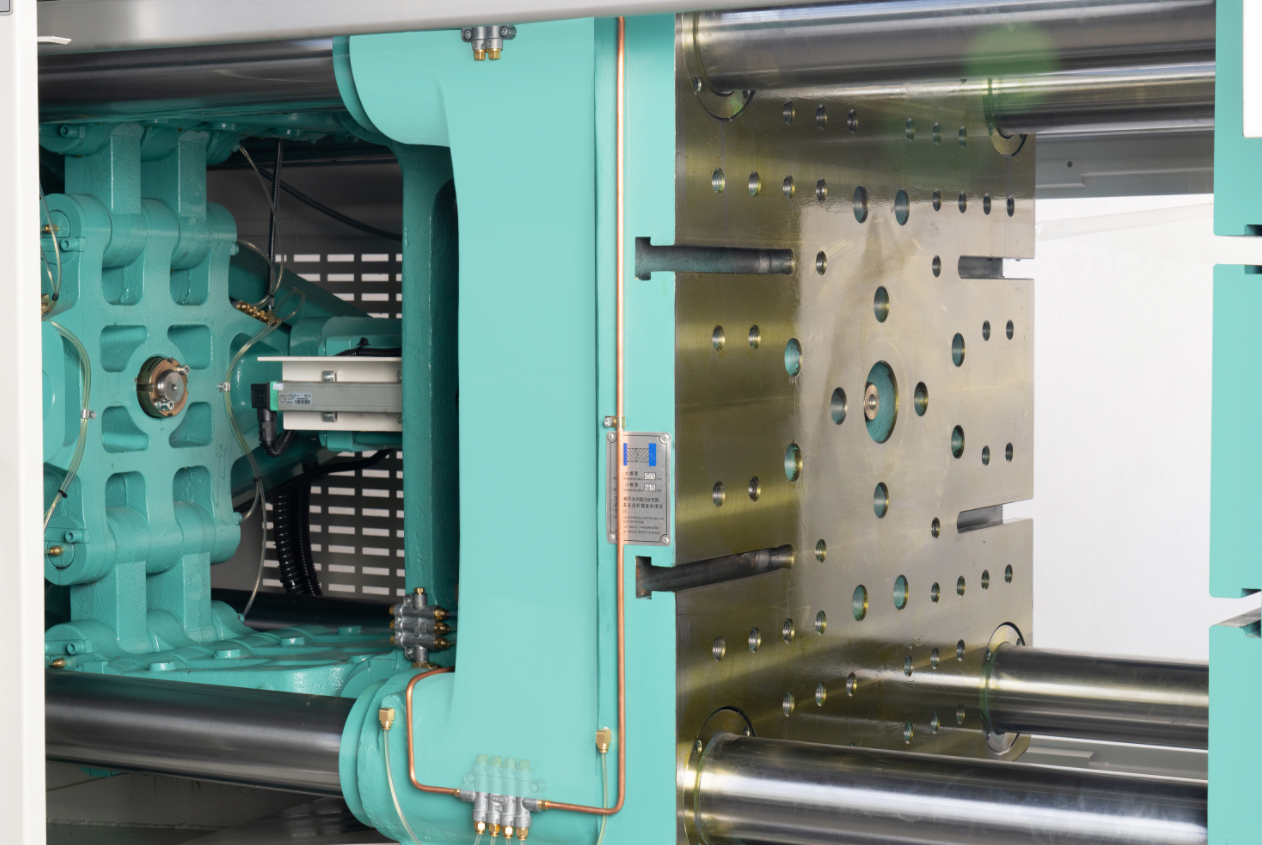

CLAMPING UNIT

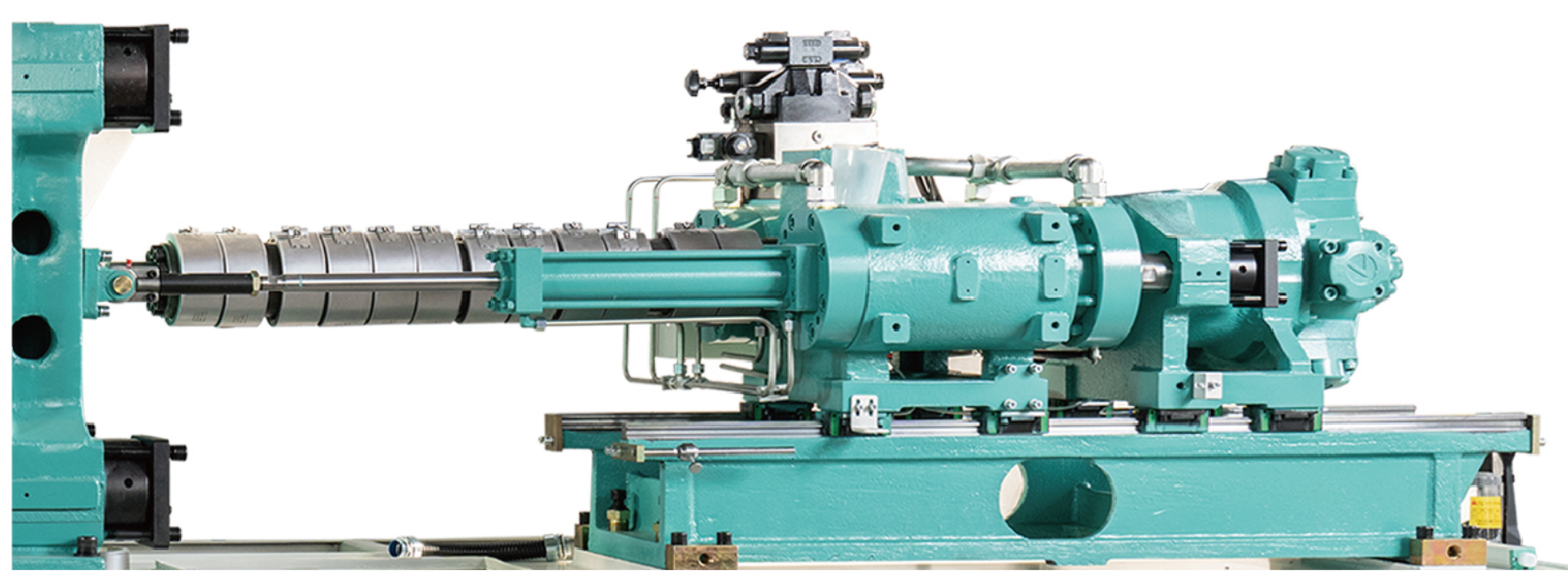

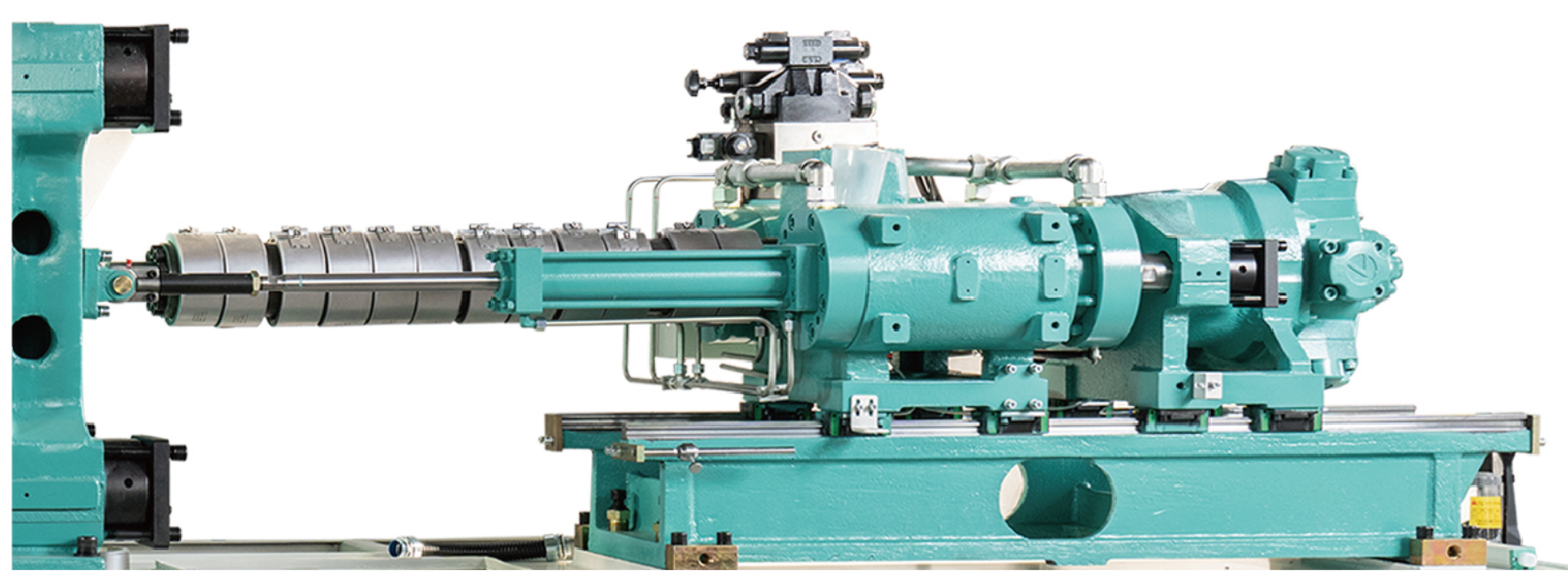

INJECTION UNIT

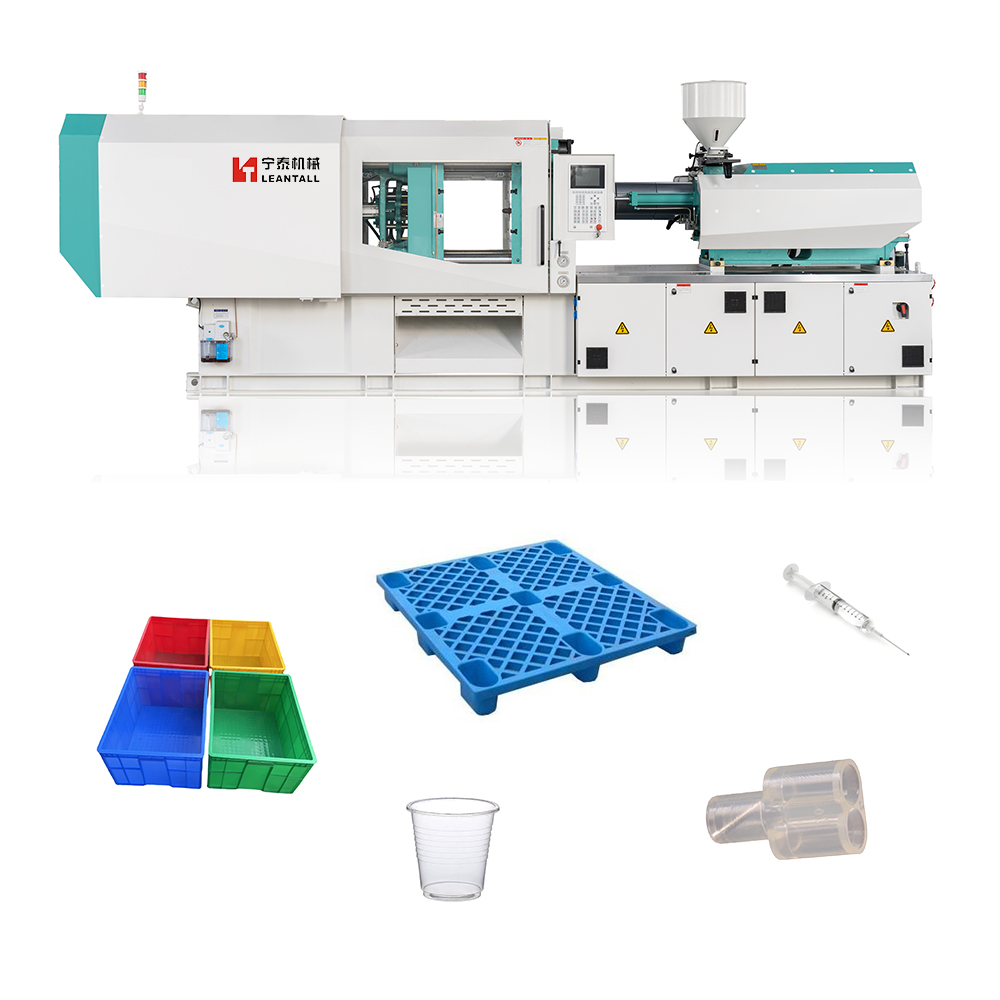

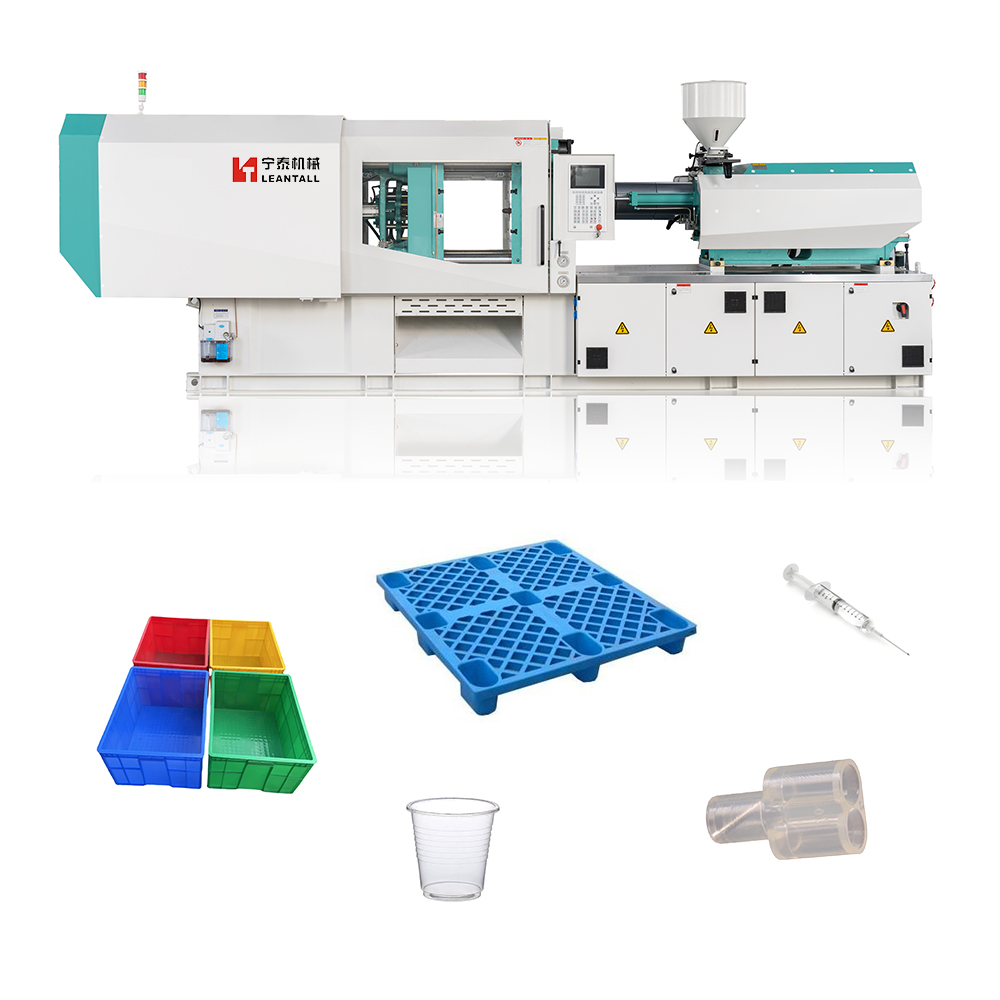

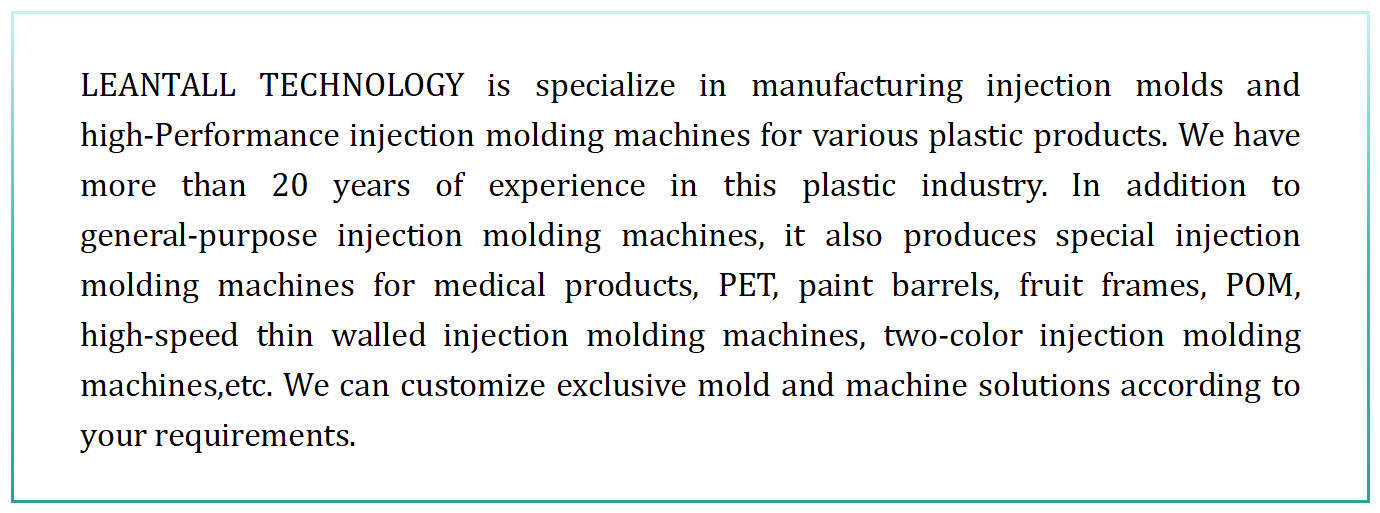

Injection molding machines are the backbone of modern plastic manufacturing, enabling the mass production of complex, high-precision plastic components used in industries from automotive to healthcare. At their core, these machines operate on a cyclic process that transforms solid plastic pellets into finished products by leveraging heat, pressure, and precision engineering. Understanding this process is key to appreciating how injection molding machines deliver consistent, efficient, and versatile production capabilities.

The working principle of an injection molding machine can be broken down into five sequential stages: material feeding and melting, injection, clamping and holding, cooling, and ejection. Each stage is tightly controlled by the machine’s central system (typically a PLC or computerized controller) to ensure product quality, repeatability, and efficiency.

Technical Parameter | |||||

Part | Name | Unit | NT320 | ||

Injection unit | SCREW DIAMETER | mm | 60 | 65 | 70 |

SCREW L/D RATIO | L/D | 21.6 | 20 | 18.5 | |

SHOT VOLUME(THEORETICAL) | CM3 | 848 | 995 | 1154 | |

INJECTION WEIGHT(PS) | g | 771 | 905 | 1050 | |

INJECTION PRESSURE | Mpa | 176 | 150 | 129 | |

INJECTION RATE | cm⊃3;/sec | 302 | 355 | 412 | |

PLASTICZATION CAPACITY(PS) | g/sec | 48 | 63 | 76 | |

INJECTION STROKE | mm | 300 | |||

INJECTION SPEED | Mm/sec | 107 | |||

SCREW SPEED | rpm | 180 | |||

Clamping unit | CLAMP FORCE | Kn | 3200 | ||

OPEN STROKE | mm | 620 | |||

SPACE BETWEEN TIE BARS | mm×mm | 660X625 | |||

MAX.MOULD HEIGHT | mm | 630 | |||

MIN.MOULD HEIGHT | mm | 230 | |||

EJECTOR STROKE | mm | 160 | |||

EJECTOR FORCE | Kn | 101 | |||

EJECTOR NUMBER | N | 13 | |||

Others | MAX.PUMP PRESSURE | Mpa | 16 | ||

PUMP MOTOR POWER | Kw | 39 | |||

HEATING POWER | Kw | 18.5 | |||

MACHINE DIMENSION(L*W*H) | m×m×m | 6.45*1.65*2.35 | |||

MACHINE WEIGHT(ESTIMATE) | T | 9.0 | |||

1. Q: What is the product range?

A: Focus on the manufacture and development of plastic injection molding machines and its auxiliary equipment such as cooling tower, chiller, etc.

2. Q: Where is your main selling market?

A: We have business domestic, USA, Russia, Indonesia, Egypt, Turkey, Uzbekistan, Pakistan, etc.

3. Q: Will you offer field installation and operator training at the buyer's factory?

A: Yes, we will arrange our skilled engineers for filed installation and training.

4. Q: What is the delivery time(equipment production time)?

A: It will be ready around 50-75 days after getting mutual confirmation about the order details and prepayment.

5. Q: Do you also have source for molds and spare parts?

A: Yes, we can offer with the competitive quality and reasonable price. Customized as required.

6. Q: What is the standard of package?

A: Wooden case packing for the auxiliary equipment, bare packing for the plastic injection molding machine. Full container shipment is highly suggest.

CLAMPING UNIT

INJECTION UNIT

Injection molding machines are the backbone of modern plastic manufacturing, enabling the mass production of complex, high-precision plastic components used in industries from automotive to healthcare. At their core, these machines operate on a cyclic process that transforms solid plastic pellets into finished products by leveraging heat, pressure, and precision engineering. Understanding this process is key to appreciating how injection molding machines deliver consistent, efficient, and versatile production capabilities.

The working principle of an injection molding machine can be broken down into five sequential stages: material feeding and melting, injection, clamping and holding, cooling, and ejection. Each stage is tightly controlled by the machine’s central system (typically a PLC or computerized controller) to ensure product quality, repeatability, and efficiency.

Technical Parameter | |||||

Part | Name | Unit | NT320 | ||

Injection unit | SCREW DIAMETER | mm | 60 | 65 | 70 |

SCREW L/D RATIO | L/D | 21.6 | 20 | 18.5 | |

SHOT VOLUME(THEORETICAL) | CM3 | 848 | 995 | 1154 | |

INJECTION WEIGHT(PS) | g | 771 | 905 | 1050 | |

INJECTION PRESSURE | Mpa | 176 | 150 | 129 | |

INJECTION RATE | cm⊃3;/sec | 302 | 355 | 412 | |

PLASTICZATION CAPACITY(PS) | g/sec | 48 | 63 | 76 | |

INJECTION STROKE | mm | 300 | |||

INJECTION SPEED | Mm/sec | 107 | |||

SCREW SPEED | rpm | 180 | |||

Clamping unit | CLAMP FORCE | Kn | 3200 | ||

OPEN STROKE | mm | 620 | |||

SPACE BETWEEN TIE BARS | mm×mm | 660X625 | |||

MAX.MOULD HEIGHT | mm | 630 | |||

MIN.MOULD HEIGHT | mm | 230 | |||

EJECTOR STROKE | mm | 160 | |||

EJECTOR FORCE | Kn | 101 | |||

EJECTOR NUMBER | N | 13 | |||

Others | MAX.PUMP PRESSURE | Mpa | 16 | ||

PUMP MOTOR POWER | Kw | 39 | |||

HEATING POWER | Kw | 18.5 | |||

MACHINE DIMENSION(L*W*H) | m×m×m | 6.45*1.65*2.35 | |||

MACHINE WEIGHT(ESTIMATE) | T | 9.0 | |||

1. Q: What is the product range?

A: Focus on the manufacture and development of plastic injection molding machines and its auxiliary equipment such as cooling tower, chiller, etc.

2. Q: Where is your main selling market?

A: We have business domestic, USA, Russia, Indonesia, Egypt, Turkey, Uzbekistan, Pakistan, etc.

3. Q: Will you offer field installation and operator training at the buyer's factory?

A: Yes, we will arrange our skilled engineers for filed installation and training.

4. Q: What is the delivery time(equipment production time)?

A: It will be ready around 50-75 days after getting mutual confirmation about the order details and prepayment.

5. Q: Do you also have source for molds and spare parts?

A: Yes, we can offer with the competitive quality and reasonable price. Customized as required.

6. Q: What is the standard of package?

A: Wooden case packing for the auxiliary equipment, bare packing for the plastic injection molding machine. Full container shipment is highly suggest.