Please Choose Your Language

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

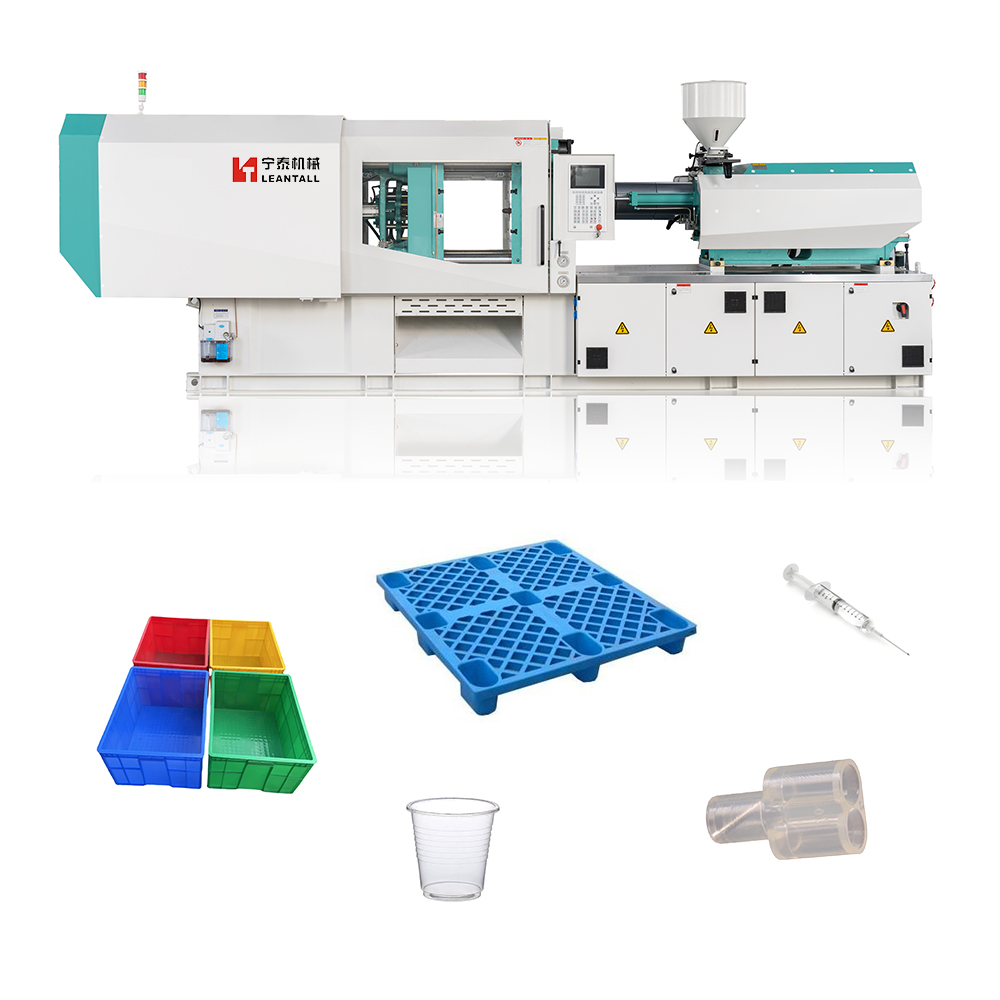

NT500

LEANTALL

8477101090

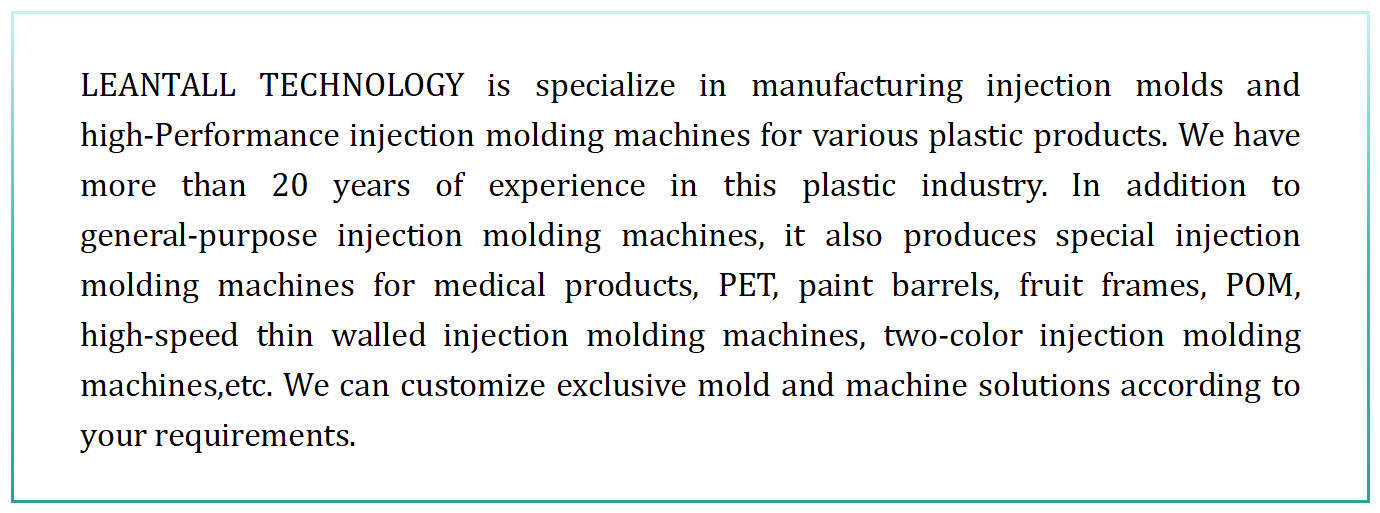

Two-color injection molding machines are designed to mold parts that require multiple colors or materials in a single injection cycle. These machines enable manufacturers to create multi-colored parts with intricate designs that would be difficult or costly to produce with traditional methods.

Dual Injection Units: These machines feature two separate injection units that can inject different materials or colors into the same mold, allowing for the creation of multi-color parts in one cycle.

Complex Molding: Two-color molding machines allow for the production of parts with two different materials, such as soft-touch grips combined with hard plastic bases, or two contrasting colors to enhance product design.

Multi-Stage Cycle: The molding process usually involves two injection stages – the first color or material is injected, followed by a second injection of a different material, either in the same mold or through rotating cores.

Consumer Electronics: Two-color housings and keypads for products like smartphones, TV remotes, and computers.

Automotive Parts: Dashboard components or interior trim pieces made from different colors or materials for both aesthetic and functional purposes.

Toys and Household Items: Many products, such as children's toys, kitchenware, and sports equipment, require multi-color molding.

Two-color injection molding machines are ideal for manufacturers looking to create aesthetically appealing and functional parts with multiple materials or colors.

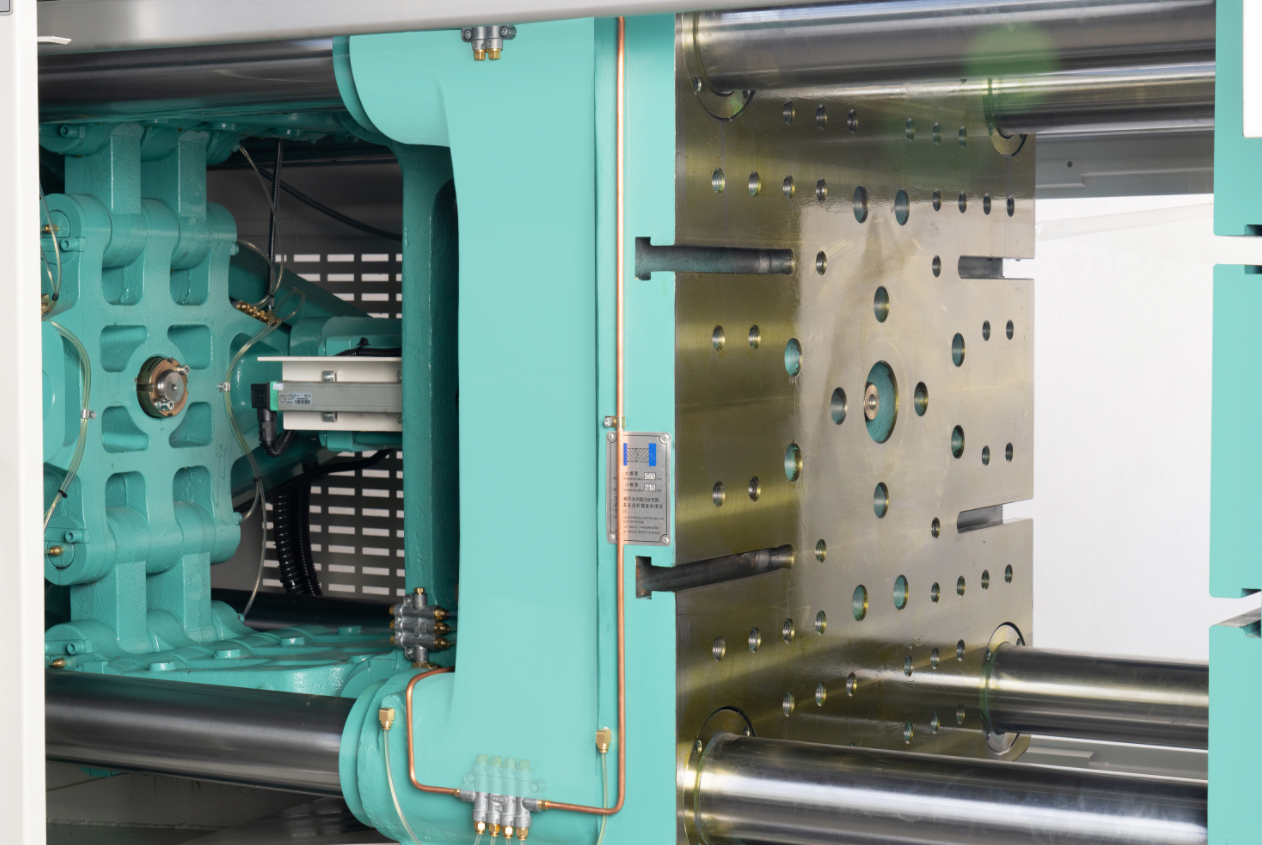

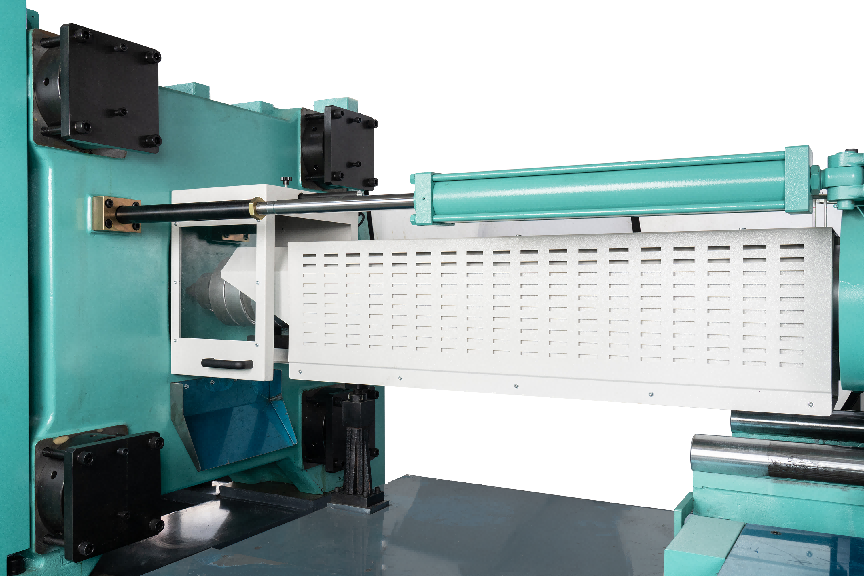

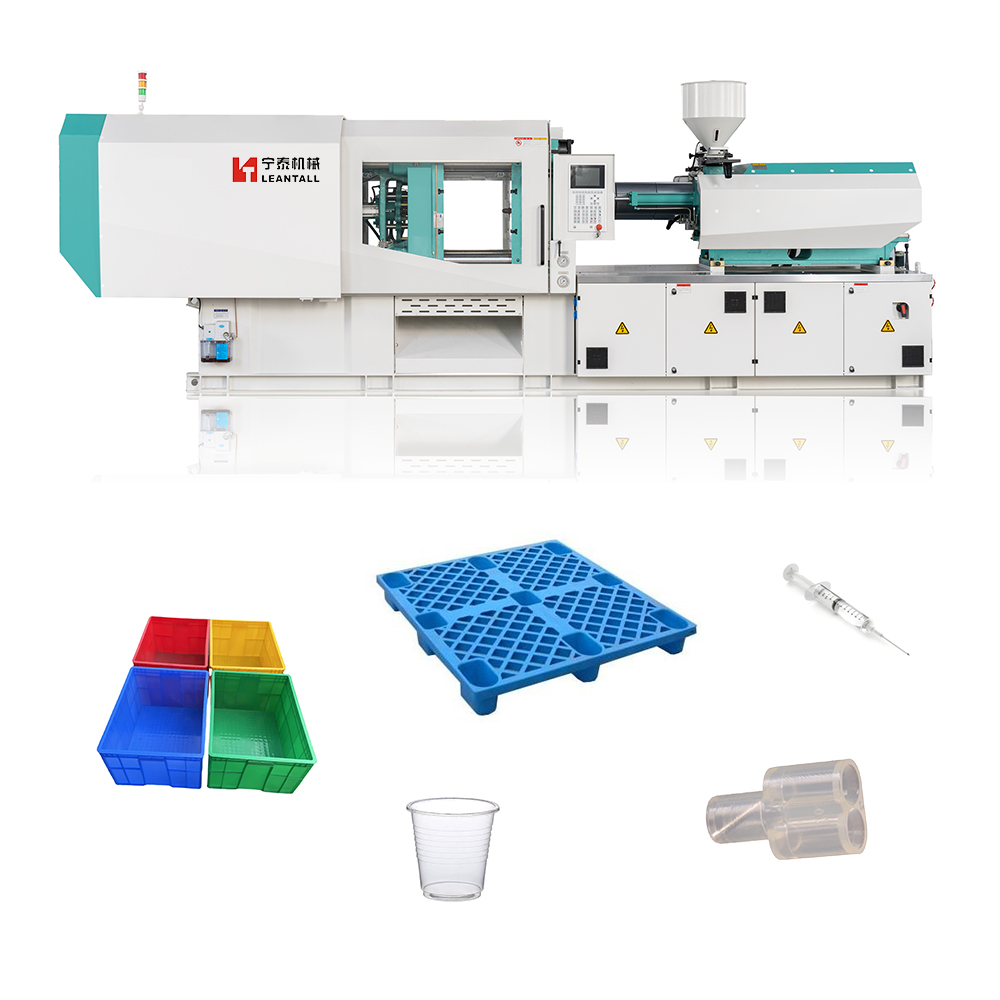

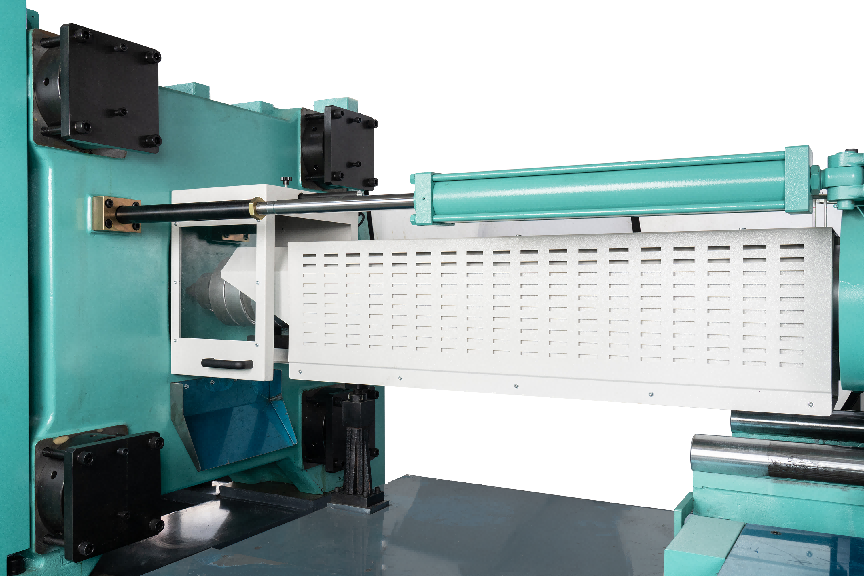

CLAMPING UNIT

High rigidity template structure design Stable operation and fast speed

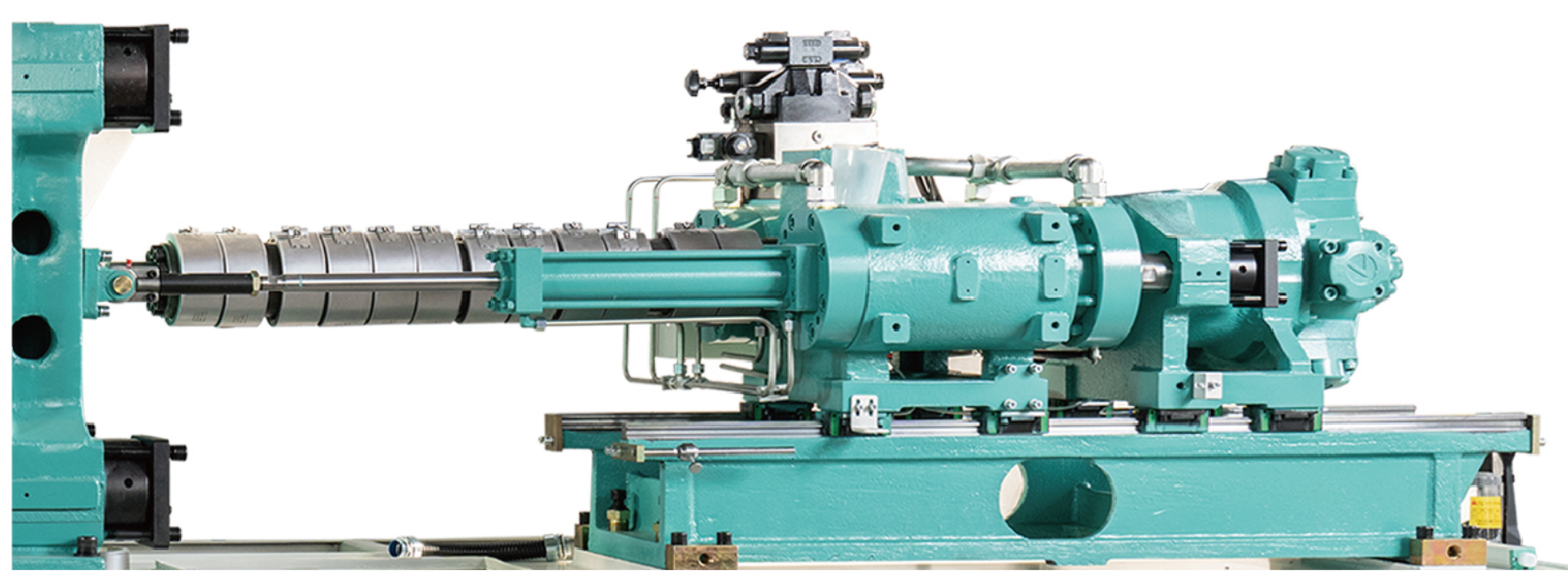

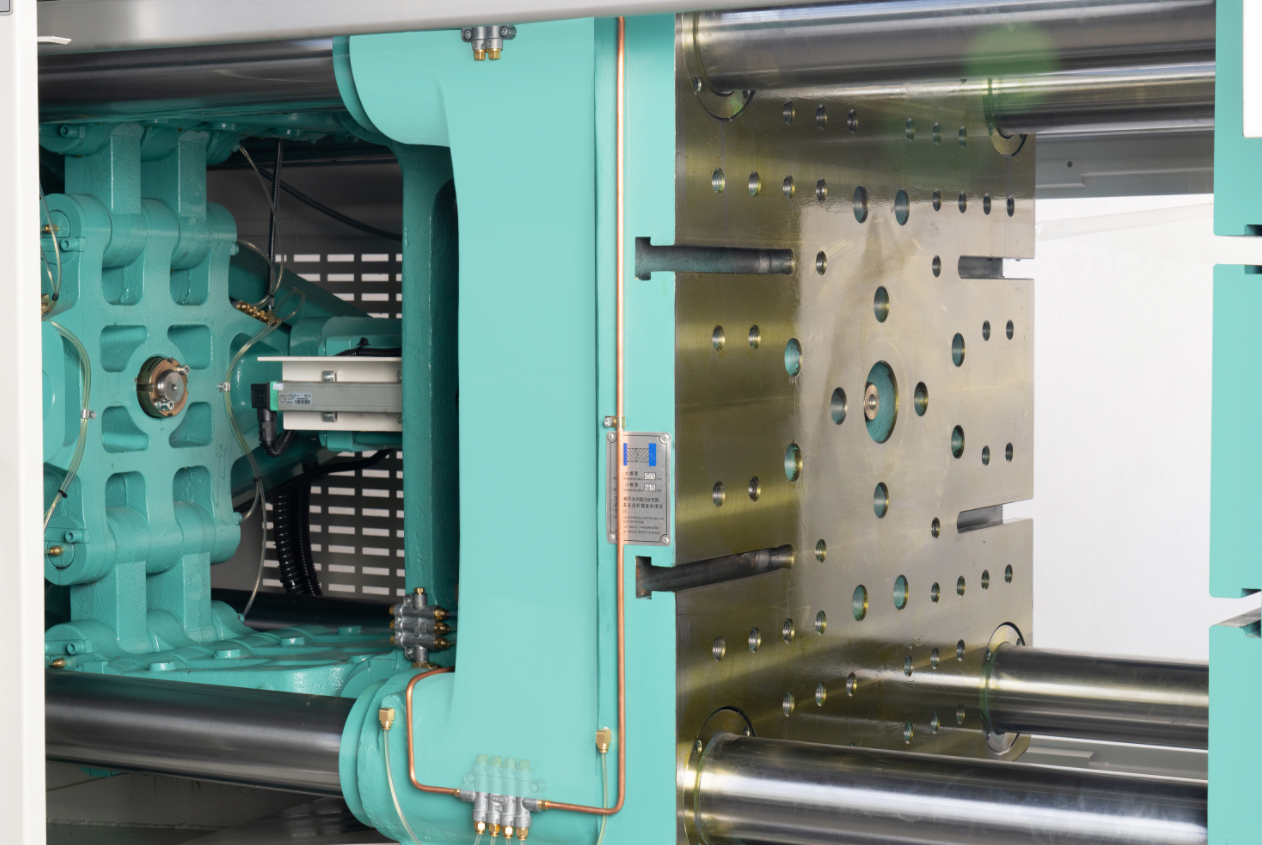

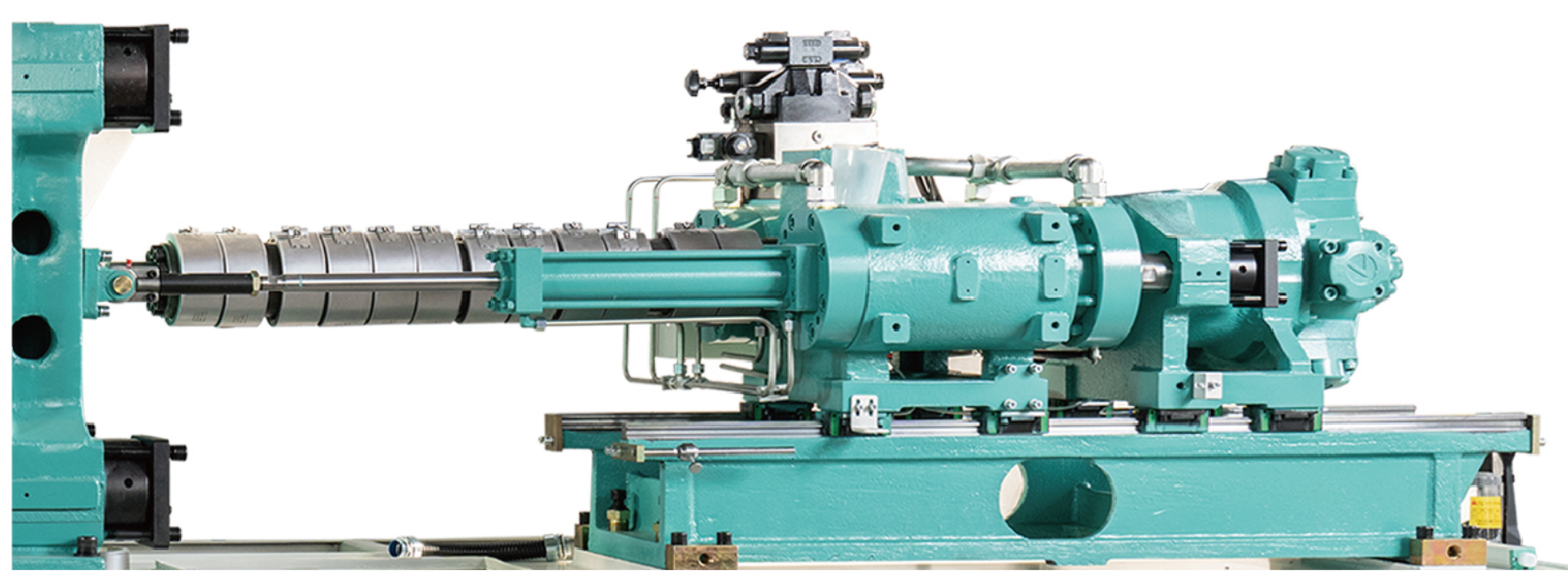

INJECTION UNIT

Powerful Performance Low Energy Consumption

Technical Parameter | |||||

Part | Name | Unit | NT500 | ||

Injection unit | SCREW DIAMETER | mm | 70 | 75 | 80 |

SCREW L/D RATIO | L/D | 21.4 | 20 | 19 | |

SHOT VOLUME(THEORETICAL) | CM3 | 1501 | 1723 | 1960 | |

INJECTION WEIGHT(PS) | g | 1366 | 1568 | 1784 | |

INJECTION PRESSURE | Mpa | 194 | 169 | 148 | |

INJECTION RATE | cm⊃3;/sec | 396 | 455 | 517 | |

PLASTICZATION CAPACITY(PS) | g/sec | 63 | 78 | 93 | |

INJECTION STROKE | mm | 390 | |||

INJECTION SPEED | Mm/sec | 103 | |||

SCREW SPEED | rpm | 160 | |||

Clamping unit | CLAMP FORCE | Kn | 5000 | ||

OPEN STROKE | mm | 800 | |||

SPACE BETWEEN TIE BARS | mm×mm | 830X780 | |||

MAX.MOULD HEIGHT | mm | 850 | |||

MIN.MOULD HEIGHT | mm | 280 | |||

EJECTOR STROKE | mm | 200 | |||

EJECTOR FORCE | Kn | 111 | |||

EJECTOR NUMBER | N | 13 | |||

Others | MAX.PUMP PRESSURE | Mpa | 16 | ||

PUMP MOTOR POWER | Kw | 50 | |||

HEATING POWER | Kw | 29.5 | |||

MACHINE DIMENSION(L*W*H) | m×m×m | 7.9*1.95*2.4 | |||

MACHINE WEIGHT(ESTIMATE) | T | 16 | |||

1. Q: What is the product range?

A: Focus on the manufacture and development of plastic injection molding machines and its auxiliary equipment such as cooling tower, chiller, etc.

2. Q: Where is your main selling market?

A: We have business domestic, USA, Russia, Indonesia, Egypt, Turkey, Uzbekistan, Pakistan, etc.

3. Q: Will you offer field installation and operator training at the buyer's factory?

A: Yes, we will arrange our skilled engineers for filed installation and training.

4. Q: What is the delivery time(equipment production time)?

A: It will be ready around 50-75 days after getting mutual confirmation about the order details and prepayment.

5. Q: Do you also have source for molds and spare parts?

A: Yes, we can offer with the competitive quality and reasonable price. Customized as required.

6. Q: What is the standard of package?

A: Wooden case packing for the auxiliary equipment, bare packing for the plastic injection molding machine. Full container shipment is highly suggest.

Two-color injection molding machines are designed to mold parts that require multiple colors or materials in a single injection cycle. These machines enable manufacturers to create multi-colored parts with intricate designs that would be difficult or costly to produce with traditional methods.

Dual Injection Units: These machines feature two separate injection units that can inject different materials or colors into the same mold, allowing for the creation of multi-color parts in one cycle.

Complex Molding: Two-color molding machines allow for the production of parts with two different materials, such as soft-touch grips combined with hard plastic bases, or two contrasting colors to enhance product design.

Multi-Stage Cycle: The molding process usually involves two injection stages – the first color or material is injected, followed by a second injection of a different material, either in the same mold or through rotating cores.

Consumer Electronics: Two-color housings and keypads for products like smartphones, TV remotes, and computers.

Automotive Parts: Dashboard components or interior trim pieces made from different colors or materials for both aesthetic and functional purposes.

Toys and Household Items: Many products, such as children's toys, kitchenware, and sports equipment, require multi-color molding.

Two-color injection molding machines are ideal for manufacturers looking to create aesthetically appealing and functional parts with multiple materials or colors.

CLAMPING UNIT

High rigidity template structure design Stable operation and fast speed

INJECTION UNIT

Powerful Performance Low Energy Consumption

Technical Parameter | |||||

Part | Name | Unit | NT500 | ||

Injection unit | SCREW DIAMETER | mm | 70 | 75 | 80 |

SCREW L/D RATIO | L/D | 21.4 | 20 | 19 | |

SHOT VOLUME(THEORETICAL) | CM3 | 1501 | 1723 | 1960 | |

INJECTION WEIGHT(PS) | g | 1366 | 1568 | 1784 | |

INJECTION PRESSURE | Mpa | 194 | 169 | 148 | |

INJECTION RATE | cm⊃3;/sec | 396 | 455 | 517 | |

PLASTICZATION CAPACITY(PS) | g/sec | 63 | 78 | 93 | |

INJECTION STROKE | mm | 390 | |||

INJECTION SPEED | Mm/sec | 103 | |||

SCREW SPEED | rpm | 160 | |||

Clamping unit | CLAMP FORCE | Kn | 5000 | ||

OPEN STROKE | mm | 800 | |||

SPACE BETWEEN TIE BARS | mm×mm | 830X780 | |||

MAX.MOULD HEIGHT | mm | 850 | |||

MIN.MOULD HEIGHT | mm | 280 | |||

EJECTOR STROKE | mm | 200 | |||

EJECTOR FORCE | Kn | 111 | |||

EJECTOR NUMBER | N | 13 | |||

Others | MAX.PUMP PRESSURE | Mpa | 16 | ||

PUMP MOTOR POWER | Kw | 50 | |||

HEATING POWER | Kw | 29.5 | |||

MACHINE DIMENSION(L*W*H) | m×m×m | 7.9*1.95*2.4 | |||

MACHINE WEIGHT(ESTIMATE) | T | 16 | |||

1. Q: What is the product range?

A: Focus on the manufacture and development of plastic injection molding machines and its auxiliary equipment such as cooling tower, chiller, etc.

2. Q: Where is your main selling market?

A: We have business domestic, USA, Russia, Indonesia, Egypt, Turkey, Uzbekistan, Pakistan, etc.

3. Q: Will you offer field installation and operator training at the buyer's factory?

A: Yes, we will arrange our skilled engineers for filed installation and training.

4. Q: What is the delivery time(equipment production time)?

A: It will be ready around 50-75 days after getting mutual confirmation about the order details and prepayment.

5. Q: Do you also have source for molds and spare parts?

A: Yes, we can offer with the competitive quality and reasonable price. Customized as required.

6. Q: What is the standard of package?

A: Wooden case packing for the auxiliary equipment, bare packing for the plastic injection molding machine. Full container shipment is highly suggest.