Please Choose Your Language

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

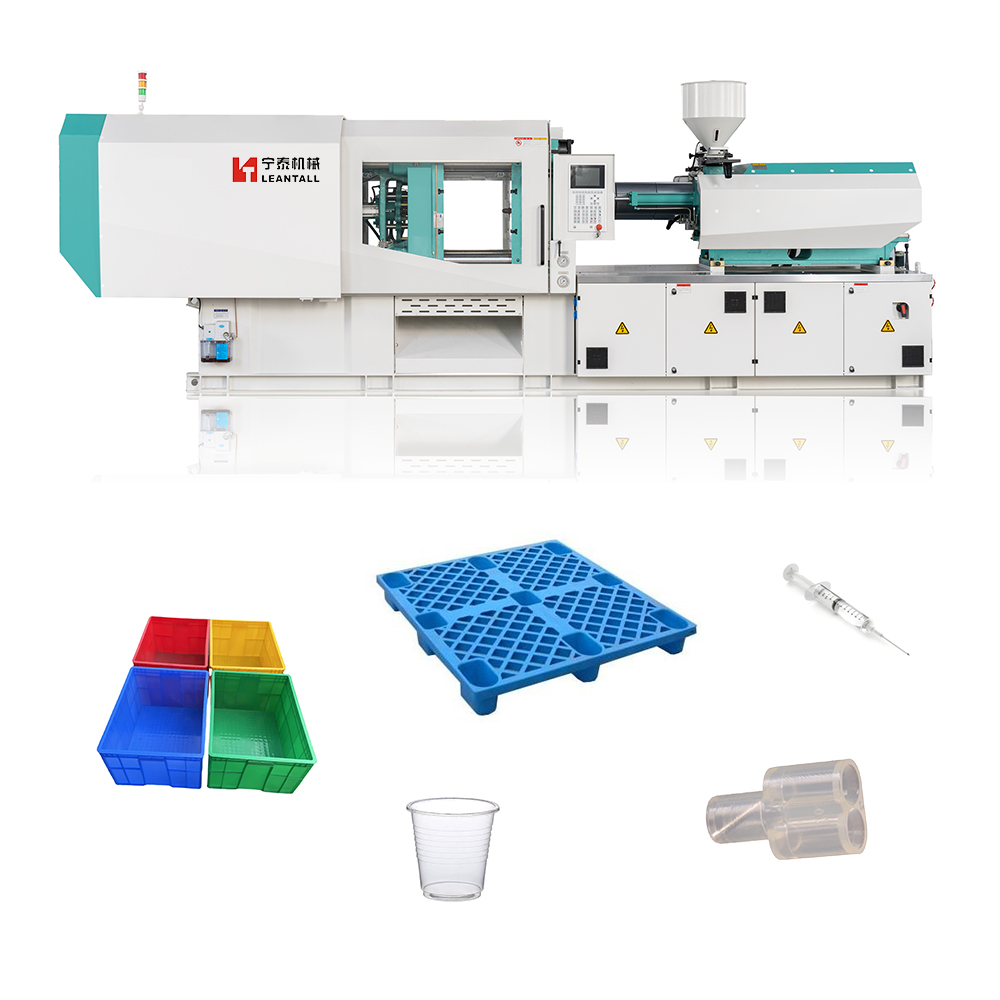

NT400

LEANTALL

8477101090

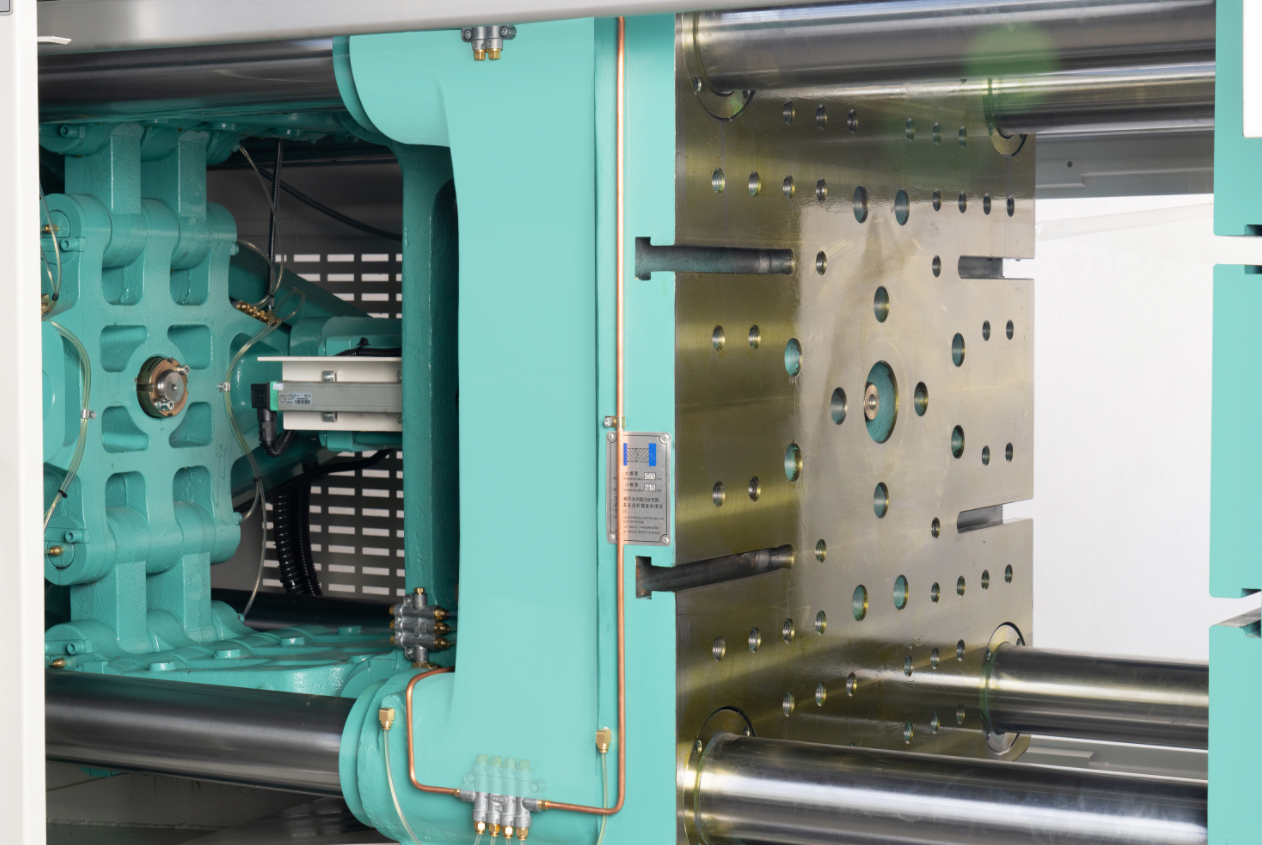

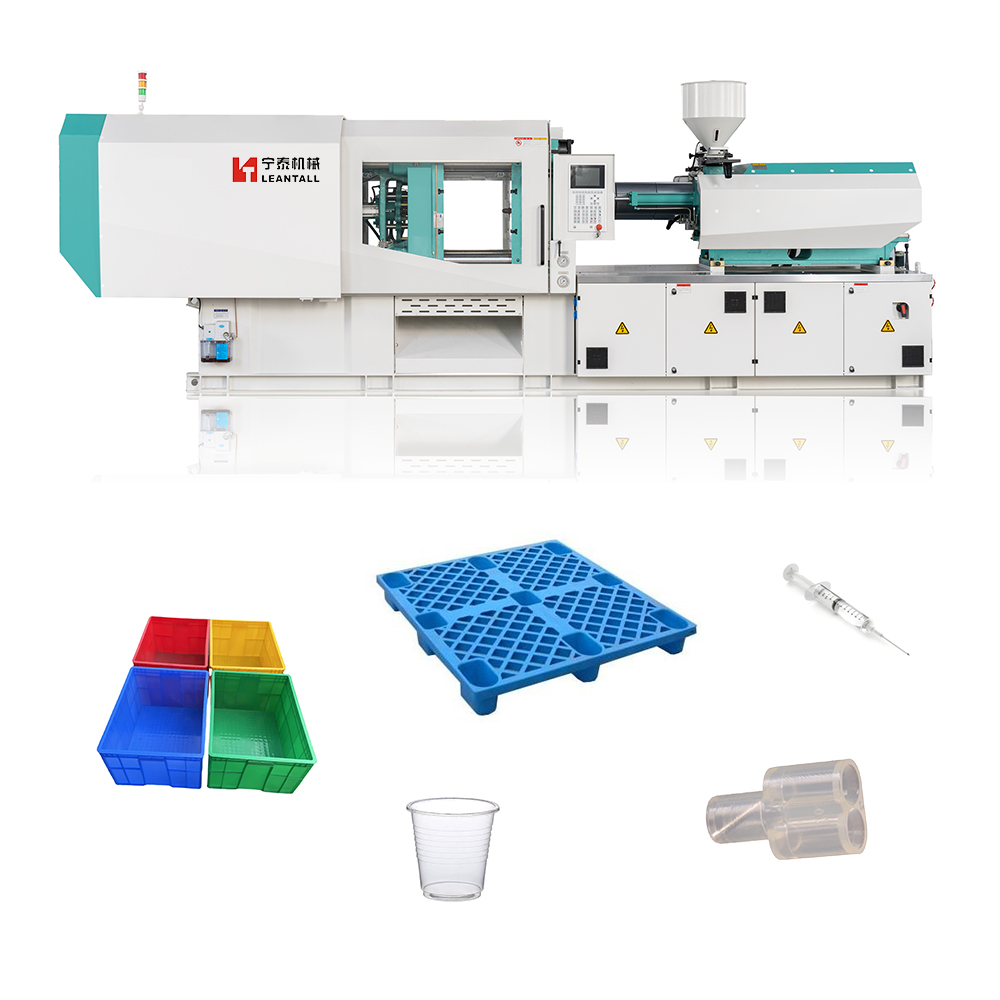

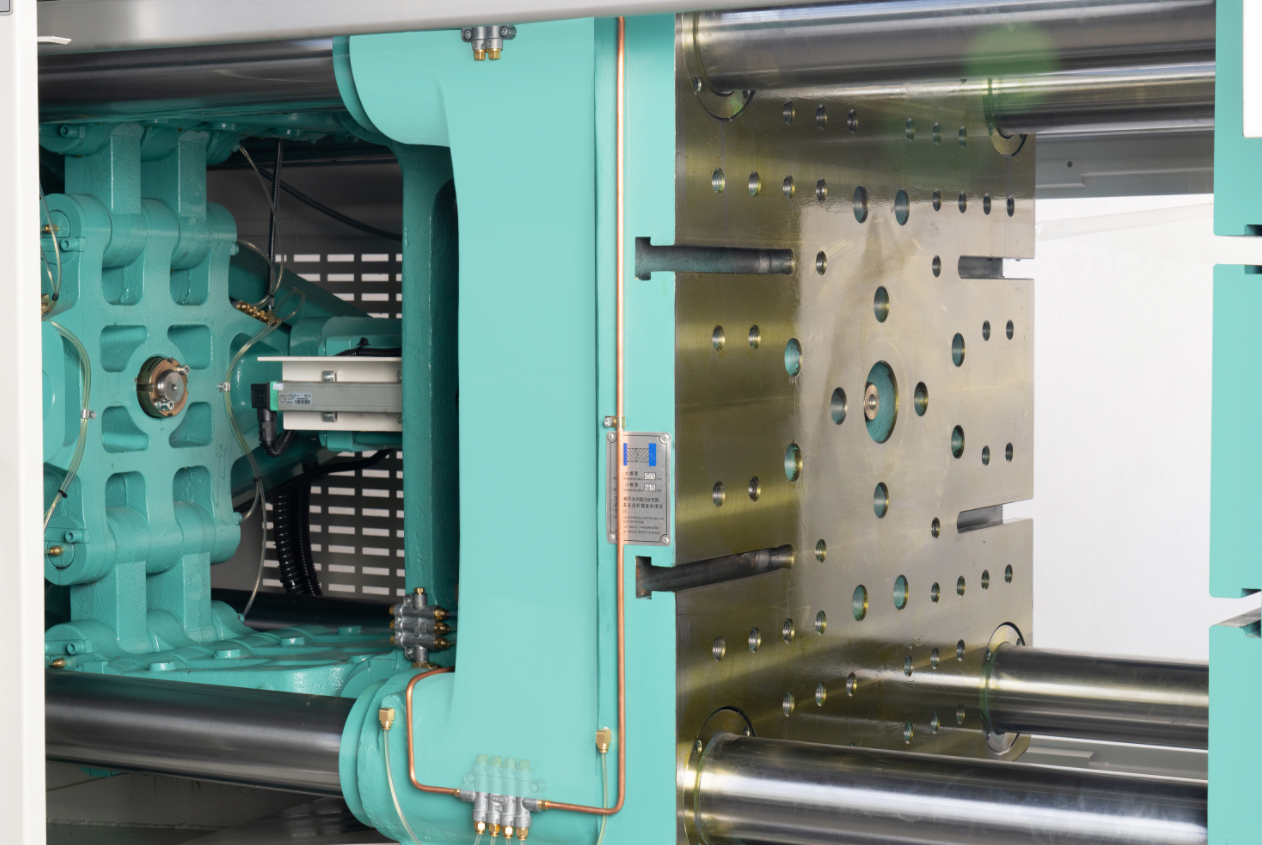

CLAMPING UNIT

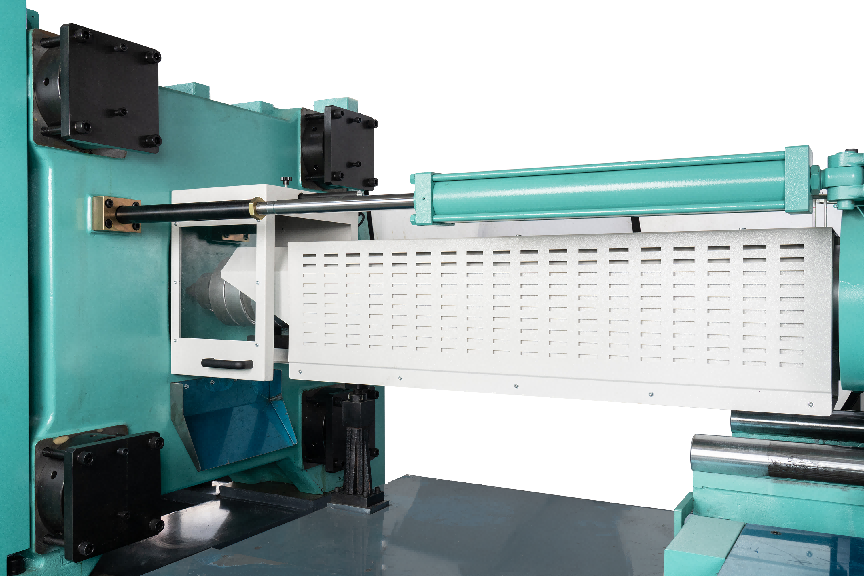

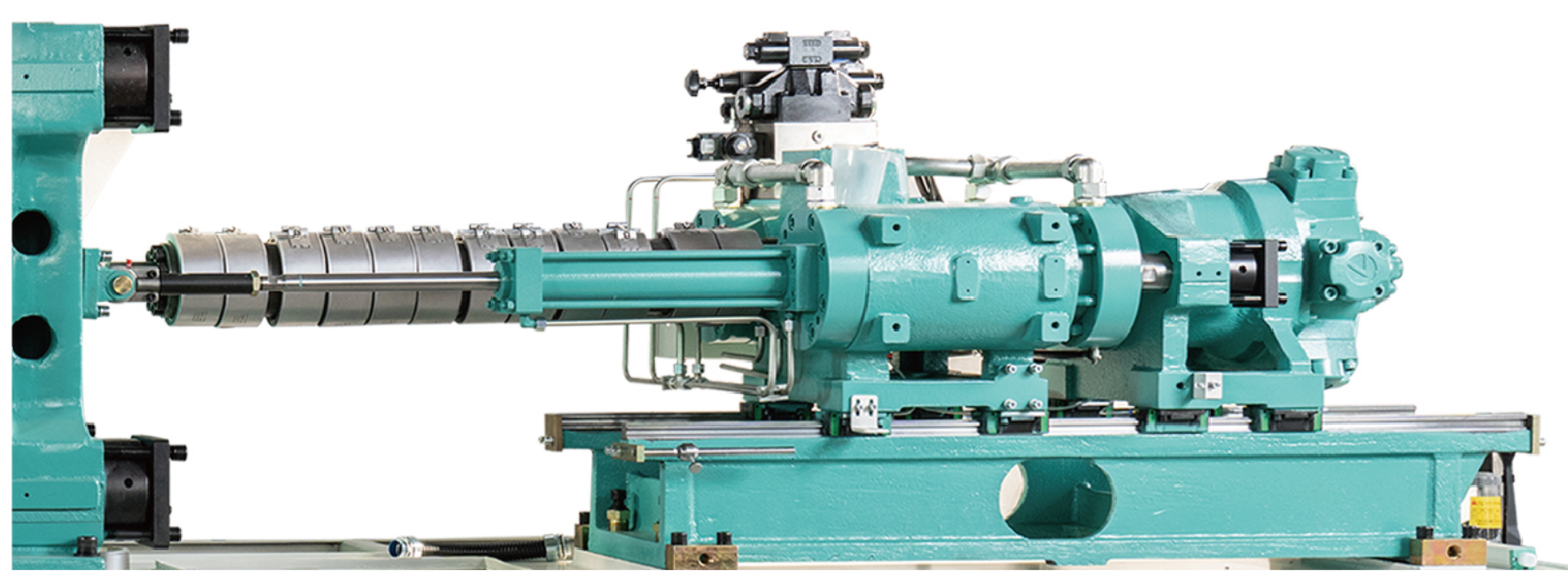

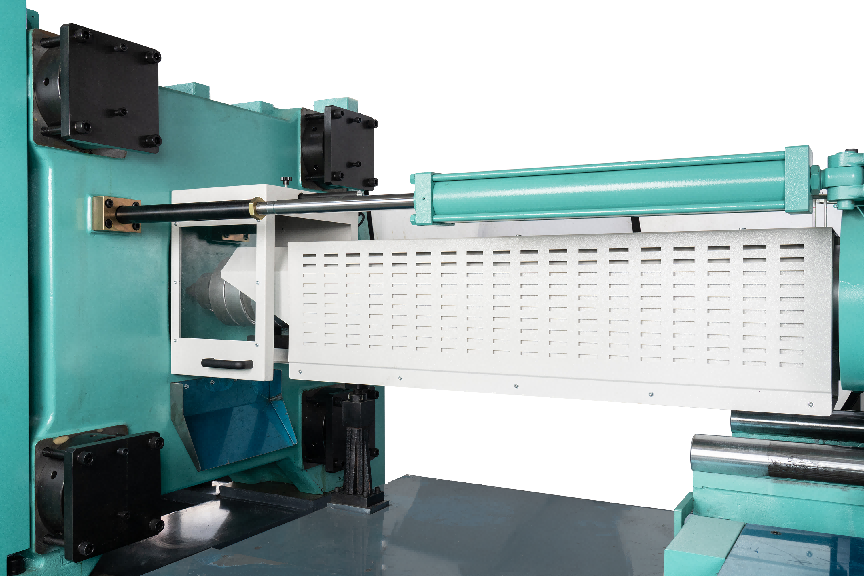

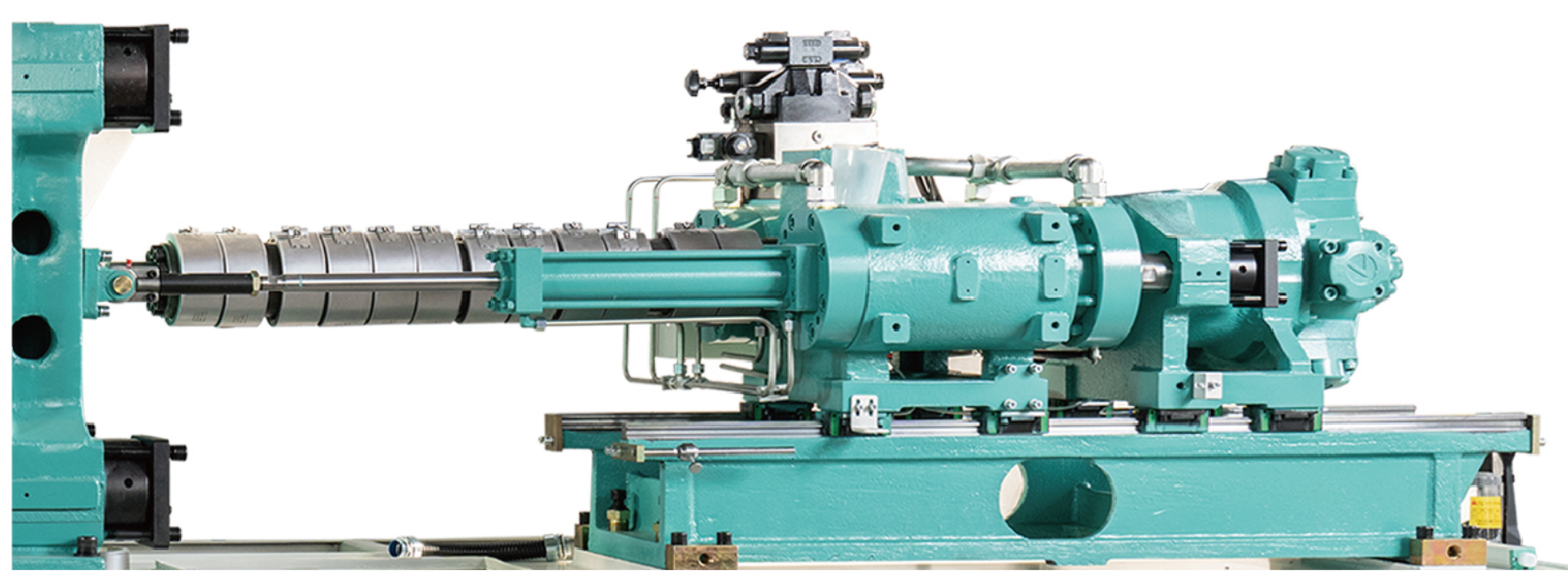

INJECTION UNIT

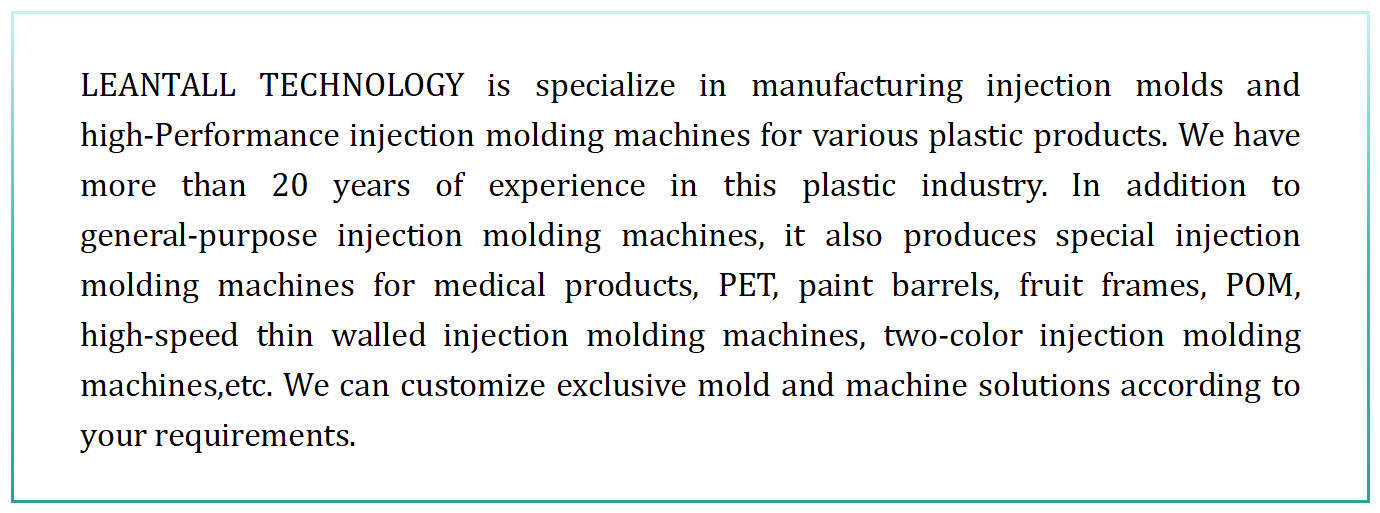

The Fast Injection Speed Injection Molding Machine is designed to inject plastic into molds at high speeds, improving cycle time and enhancing the production of intricate, high-precision parts. Speed is particularly important in industries with large-scale production runs, like automotive and electronics.

High-Pressure Injection: These machines use high-speed injection units capable of injecting molten plastic rapidly into molds without compromising material flow or part quality.

Precision Control: Advanced control systems ensure that injection speeds are consistent and precise, preventing defects like flash or uneven fill.

High Throughput: By reducing the time required for each molding cycle, these machines can produce large quantities of parts in a shorter period.

Automotive Parts: Fast injection speeds are ideal for producing small and medium-sized automotive components quickly.

Electronics Enclosures: Fast injection ensures that complex parts with tight tolerances are produced in high volume.

Packaging: Fast injection speeds are ideal for producing high volumes of molded packaging items, such as containers and lids.

Technical Parameter | |||||

Part | Name | Unit | NT400 | ||

Injection unit | SCREW DIAMETER | mm | 70 | 75 | 80 |

SCREW L/D RATIO | L/D | 21.4 | 20 | 19 | |

SHOT VOLUME(THEORETICAL) | CM3 | 1501 | 1723 | 1960 | |

INJECTION WEIGHT(PS) | g | 1366 | 1568 | 1784 | |

INJECTION PRESSURE | Mpa | 194 | 169 | 148 | |

INJECTION RATE | cm⊃3;/sec | 396 | 455 | 517 | |

PLASTICZATION CAPACITY(PS) | g/sec | 63 | 78 | 93 | |

INJECTION STROKE | mm | 390 | |||

INJECTION SPEED | Mm/sec | 103 | |||

SCREW SPEED | rpm | 160 | |||

Clamping unit | CLAMP FORCE | Kn | 4000 | ||

OPEN STROKE | mm | 725 | |||

SPACE BETWEEN TIE BARS | mm×mm | 730X730 | |||

MAX.MOULD HEIGHT | mm | 800 | |||

MIN.MOULD HEIGHT | mm | 300 | |||

EJECTOR STROKE | mm | 180 | |||

EJECTOR FORCE | Kn | 111 | |||

EJECTOR NUMBER | N | 13 | |||

Others | MAX.PUMP PRESSURE | Mpa | 16 | ||

PUMP MOTOR POWER | Kw | 50 | |||

HEATING POWER | Kw | 29.5 | |||

MACHINE DIMENSION(L*W*H) | m×m×m | 7.6*1.85*2.35 | |||

MACHINE WEIGHT(ESTIMATE) | T | 13 | |||

1. Q: What is the product range?

A: Focus on the manufacture and development of plastic injection molding machines and its auxiliary equipment such as cooling tower, chiller, etc.

2. Q: Where is your main selling market?

A: We have business domestic, USA, Russia, Indonesia, Egypt, Turkey, Uzbekistan, Pakistan, etc.

3. Q: Will you offer field installation and operator training at the buyer's factory?

A: Yes, we will arrange our skilled engineers for filed installation and training.

4. Q: What is the delivery time(equipment production time)?

A: It will be ready around 50-75 days after getting mutual confirmation about the order details and prepayment.

5. Q: Do you also have source for molds and spare parts?

A: Yes, we can offer with the competitive quality and reasonable price. Customized as required.

6. Q: What is the standard of package?

A: Wooden case packing for the auxiliary equipment, bare packing for the plastic injection molding machine. Full container shipment is highly suggest.

CLAMPING UNIT

INJECTION UNIT

The Fast Injection Speed Injection Molding Machine is designed to inject plastic into molds at high speeds, improving cycle time and enhancing the production of intricate, high-precision parts. Speed is particularly important in industries with large-scale production runs, like automotive and electronics.

High-Pressure Injection: These machines use high-speed injection units capable of injecting molten plastic rapidly into molds without compromising material flow or part quality.

Precision Control: Advanced control systems ensure that injection speeds are consistent and precise, preventing defects like flash or uneven fill.

High Throughput: By reducing the time required for each molding cycle, these machines can produce large quantities of parts in a shorter period.

Automotive Parts: Fast injection speeds are ideal for producing small and medium-sized automotive components quickly.

Electronics Enclosures: Fast injection ensures that complex parts with tight tolerances are produced in high volume.

Packaging: Fast injection speeds are ideal for producing high volumes of molded packaging items, such as containers and lids.

Technical Parameter | |||||

Part | Name | Unit | NT400 | ||

Injection unit | SCREW DIAMETER | mm | 70 | 75 | 80 |

SCREW L/D RATIO | L/D | 21.4 | 20 | 19 | |

SHOT VOLUME(THEORETICAL) | CM3 | 1501 | 1723 | 1960 | |

INJECTION WEIGHT(PS) | g | 1366 | 1568 | 1784 | |

INJECTION PRESSURE | Mpa | 194 | 169 | 148 | |

INJECTION RATE | cm⊃3;/sec | 396 | 455 | 517 | |

PLASTICZATION CAPACITY(PS) | g/sec | 63 | 78 | 93 | |

INJECTION STROKE | mm | 390 | |||

INJECTION SPEED | Mm/sec | 103 | |||

SCREW SPEED | rpm | 160 | |||

Clamping unit | CLAMP FORCE | Kn | 4000 | ||

OPEN STROKE | mm | 725 | |||

SPACE BETWEEN TIE BARS | mm×mm | 730X730 | |||

MAX.MOULD HEIGHT | mm | 800 | |||

MIN.MOULD HEIGHT | mm | 300 | |||

EJECTOR STROKE | mm | 180 | |||

EJECTOR FORCE | Kn | 111 | |||

EJECTOR NUMBER | N | 13 | |||

Others | MAX.PUMP PRESSURE | Mpa | 16 | ||

PUMP MOTOR POWER | Kw | 50 | |||

HEATING POWER | Kw | 29.5 | |||

MACHINE DIMENSION(L*W*H) | m×m×m | 7.6*1.85*2.35 | |||

MACHINE WEIGHT(ESTIMATE) | T | 13 | |||

1. Q: What is the product range?

A: Focus on the manufacture and development of plastic injection molding machines and its auxiliary equipment such as cooling tower, chiller, etc.

2. Q: Where is your main selling market?

A: We have business domestic, USA, Russia, Indonesia, Egypt, Turkey, Uzbekistan, Pakistan, etc.

3. Q: Will you offer field installation and operator training at the buyer's factory?

A: Yes, we will arrange our skilled engineers for filed installation and training.

4. Q: What is the delivery time(equipment production time)?

A: It will be ready around 50-75 days after getting mutual confirmation about the order details and prepayment.

5. Q: Do you also have source for molds and spare parts?

A: Yes, we can offer with the competitive quality and reasonable price. Customized as required.

6. Q: What is the standard of package?

A: Wooden case packing for the auxiliary equipment, bare packing for the plastic injection molding machine. Full container shipment is highly suggest.